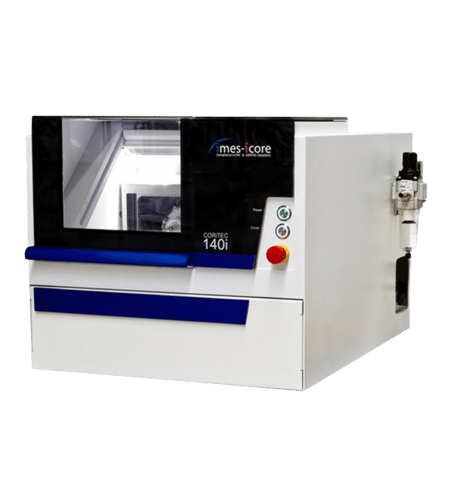

Imes-Icore

CORiTEC 140i

Specialized for Processing CAD/CAM Blocks

The CORiTEC 140i machine system is perfectly suited for everyday use for grinding virtually all block materials available on the market. The machine can produce restorations directly, in combination with an intraoral scanner.

A Practical Solution for

Dental Labs

The CORiTEC 140i is often used as a special machine in labs and milling centers for special wet processing of a wide variety of block materials. The stable industrial design of the machine makes processing in the highest quality possible – even the production of prefabricated abutment.

Watch the CORiTEC 140i in action >

CORiTEC 140i Key Features

Wet & Dry

A fully integrated wet machining with filter system

Priced for Performance

The attractive price-performance ratio ensures short payback time

4-Axis Freedom

4-axis machining of material blocks with undercut detection

60.000 RPM

Achieve the highest precision through a high-frequency spindle

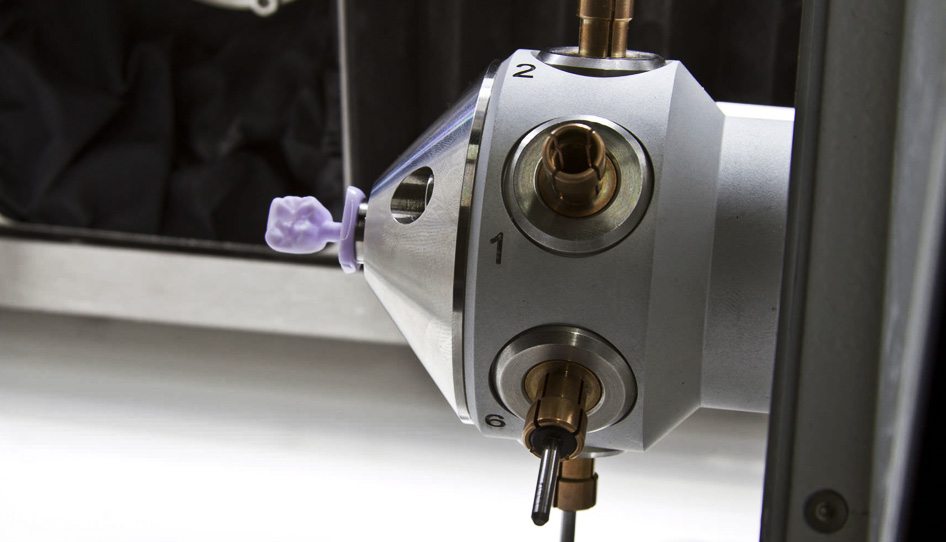

6-Fold

Increase productivity with an automatic tool changer with tool management

Multi-Adapter

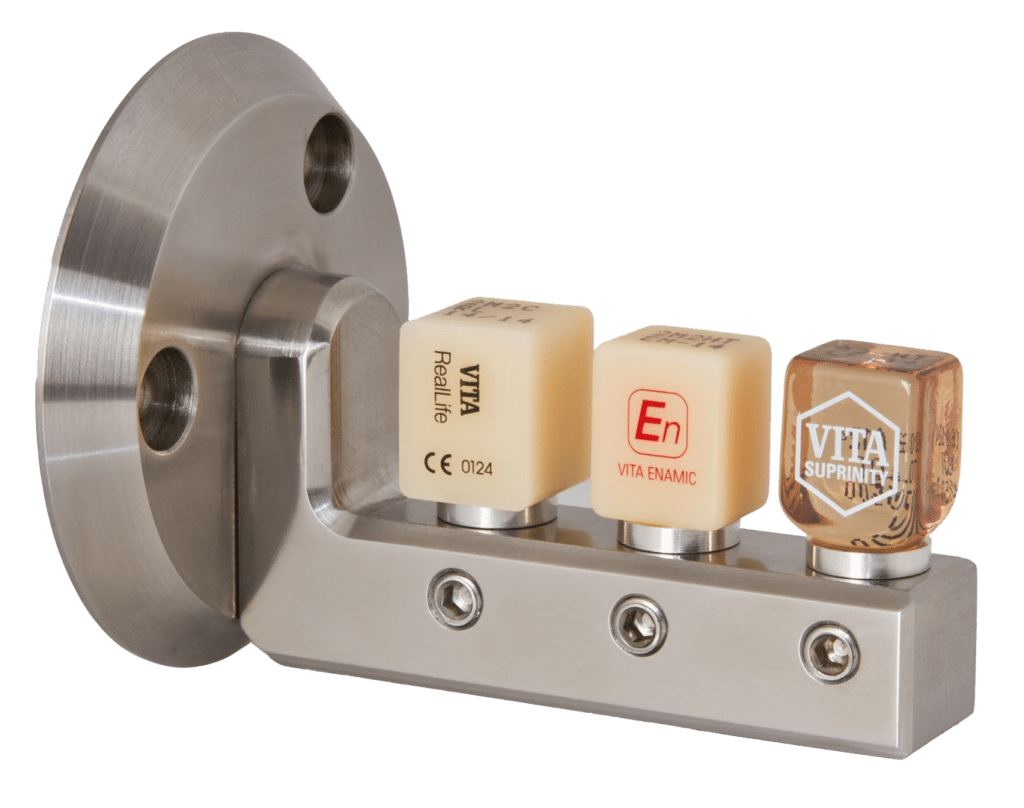

The multi-adapter allows up to 3 blocks for greater effeciency

CORiTEC 140i Advantages

High Performance Block Processing

The CORiTEC 140i processes all standard CAD/CAM blocks, such as glass ceramics, lithium disilicate, or feldspar. The multi-adapter allows up to three blocks to be processed simultaneously and 4-axis machining — with undercut detection — allows for efficient, high-precision results.

Automated for Efficiency

The CORiTEC 140i features an automatic 6-fold tool changer with tool management to simplify the milling process. Paired with a high-frequency spindle (up to 60,000 rpm) and a flexible adapter for different CAD/CAM block systems, the 140i is perfectly suited for everyday use in any lab environment.

CORiTEC 140i Specifications

# of Axles & Machining Type |

# of Axles & Machining Type4 axes, simultaneous machining |

Max. Tilt Angle (Rotary Axis) |

Max. Tilt Angle (Rotary Axis)360 degree processing possible |

Wet Processing |

Wet ProcessingIntegrated |

Spindle Max. |

Spindle Max.60,000 rpm / 0.4kW |

Axle Drives |

Axle DrivesMicrostep motors |

Tool Fitting |

Tool Fitting3mm shaft |

Tool Changer |

Tool Changer6-fold |

Workpiece Changer |

Workpiece Changermanual/1 and 3 way adapter possible/block processing |

Weight |

Weight55kg |

Width x Depth x Height |

Width x Depth x Height430 x 528 x 365mm |

Main voltage/frequency/power |

Main voltage/frequency/power100V-240V/50-60Hz/800W |

Compressed Air Supply |

Compressed Air Supply6-9 bar constant supply, 50 litres/minute |

Materials |

Materialsprefabricated abutment, zirconium dioxide, alimunium oxide, PMMA, plastics, composites, wax, glass ceramics, hybrid ceramics |

Compatibility |

CompatibilityCAD/CAM blocks (1 & 3 fold adapter), Medentika PreFace abutments |