CORiTEC 350i series

imes-icore®

CORiTEC 350i series

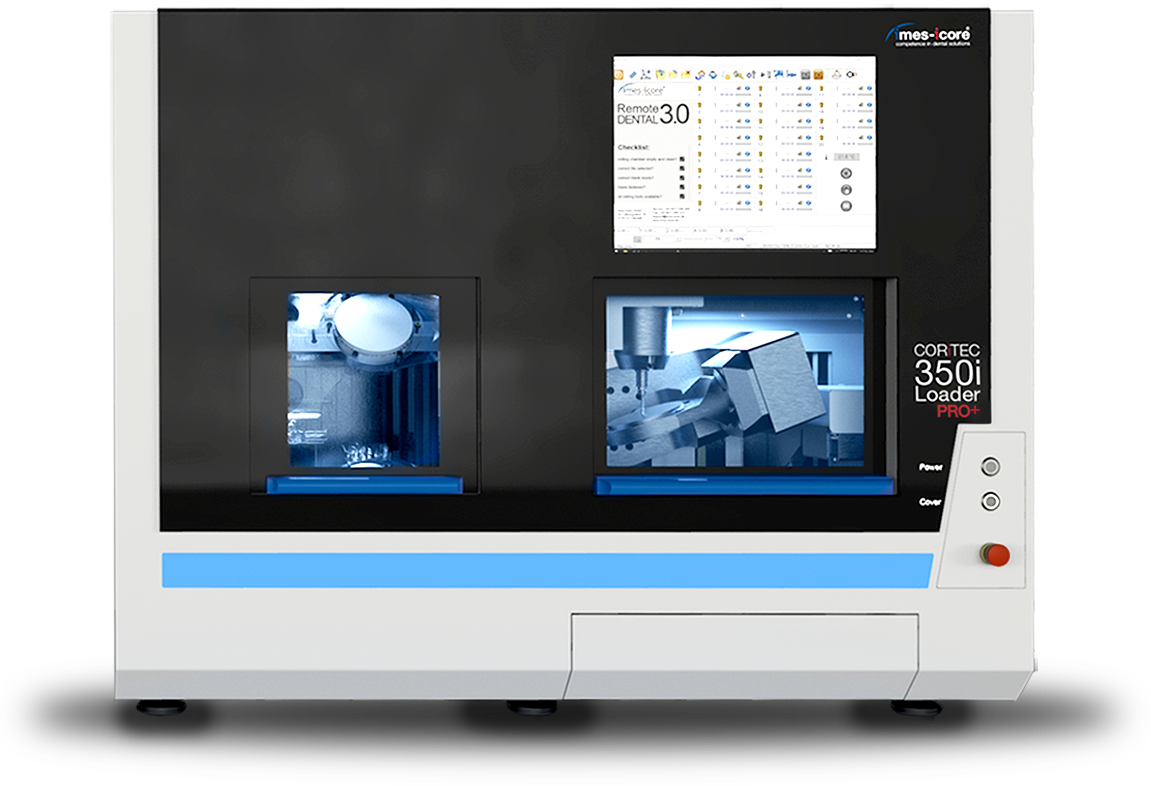

The Automated All-In-One Solution

The CORiTEC 350i series from imes-icore are the ultimate milling machines for dental production. Their unique capabilities and automation systems make them ideal for demanding production environments where accuracy, efficiency, reliability, and throughput are essential. Their robust design allows for the processing of a range of materials including glass ceramics, composites, polymers, pre-milled abutments, and metals.

20% faster milling with optimum precision

The high-resolution dynamic servo motors with absolute measuring systems used in the CORiTEC 350i PRO series guarantee up to 20 % faster machining with optimum precision. This machine system is constructed from a one-piece machine frame made of polymer concrete, hence ensuring the highest possible stability for vibration-free machining. The CORiTEC 350i Loader PRO, with a fully automated blank magazine, permits all-around machining of up to 12 blanks in unmanned operation. Due to the precise repositioning of the zero-point clamping system, different PreFab abutment holders can be used.

As already implemented in the CORiTEC 350i PRO, the CORiTEC 350i PRO+ series also comes with high-resolution dynamic servo motors and extraordinary measuring systems. To use this advanced technology and to be able to exploit its full potential, the CORiTEC 350i PRO+ is equipped with a water-cooled, powerful 3-fold hybrid ball bearing 3.6 kW milling spindle. The massive stainless steel blank holders help to reach stability and reduce vibrations. The water cooling ensures a constant temperature of the milling spindle, thus significantly minimizing its thermal expansion.

Key Benefits

Available Models

CORiTEC 350i PRO

imes-icore® CORiTEC 350i PRO

Specs

- servo with absolute encoder

- 32.000 Inc (0.15 µm) resolution

- polymer concrete, steel rails

- 15″ HD touchscreen

- shiny design, LED illumination

- manual blank changer

- zero point clamping system inclusive

- 2 blank holder

- 1. kW spindle power

- 2 hybrid spindle bearings

- 6 mm collet

- air cooled spindle

CORiTEC 350i PRO+

imes-icore® CORiTEC 350i PRO+

Specs

- servo with absolute encoder

- 32.000 Inc (0.15 µm) resolution

- polymer concrete, steel rails

- 15″ HD touchscreen

- shiny design, LED illumination

- manual blank changer

- zero point clamping system inclusive

- 2 stainless steel blank holder

- 3.6 kW spindle power

- 3 hybrid spindle bearings

- 6 mm collet (self-cleaning)

- water cooled spindle

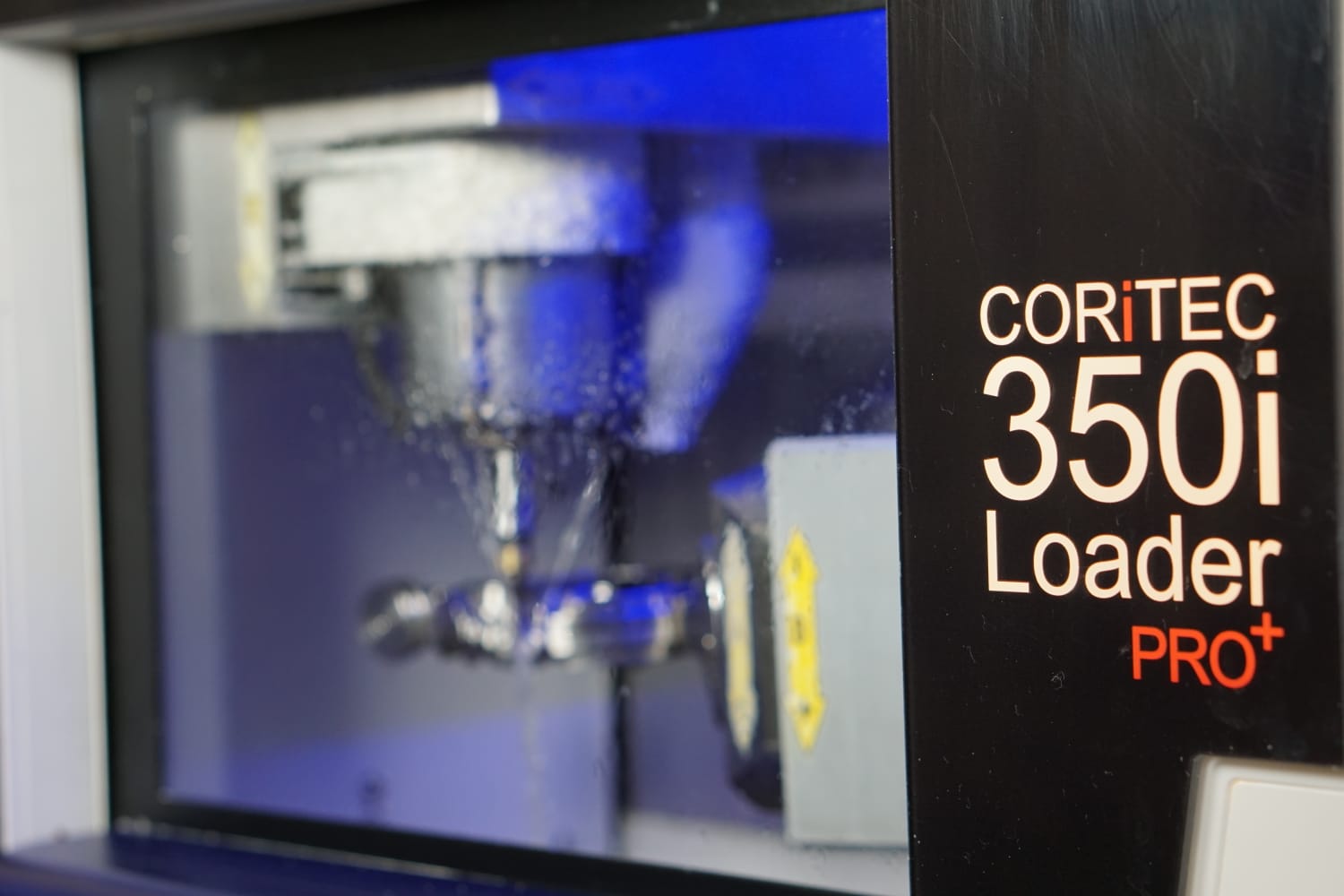

CORiTEC 350i Loader PRO

imes-icore® CORiTEC 350i Loader PRO

Specs

- servo with absolute encoder

- 32.000 Inc (0.15 µm) resolution

- polymer concrete, steel rails

- 15″ HD touchscreen

- shiny design, LED illumination

- 12-fold automatic blank changer

- zero point clamping system inclusive

- 8 blank holder

- 1. kW spindle power

- 2 hybrid spindle bearings

- 6 mm collet

- air cooled spindle

CORiTEC 350i Loader PRO+

Material: imes-icore® CORiTEC 350i Loader PRO+

Specs

- servo with absolute encoder

- 32.000 Inc (0.15 µm) resolution

- polymer concrete, steel rails

- 15″ HD touchscreen

- shiny design, LED illumination

- 12-fold automatic blank changer

- zero point clamping system inclusive

- 8 stainless steel blank holder

- 3.6 kW spindle power

- 3 hybrid spindle bearings

- 6 mm collet (self-cleaning)

- water cooled spindle

Key Features

CORiTEC® 350i series

350i PRO/350i Loader PRO

- Integrated Wet and Dry processing

- Integrated temperature compensation

- All CAD/CAM materials can be processed

- Absolute measuring system in all axes

- Zero-point clamping system

- 20-fold tool changer

- 15″ touchscreen

- Polymere concrete base structure

350i PRO+/350i Loader PRO+

- Integrated Wet and Dry processing

- Integrated temperature compensation

- High-resolution dynamic servo motors with absolute measuring system

- Optional ionizer possible

- 20-fold tool changer

- Stainless Steel blank holder

- High-dynamic servo drives for up to 20% faster processing

iCAM v5 smart

- 5-axis simultaneous machining for the CORiTEC 150i, 250i, 350i & 650i including implant module

iCAM v5 smart expert

- 5-axis simultaneous machining for the CORiTEC 150i & 250i, 350i & 650i, including access to the open development interface for the creation of own milling strategies

Materials

Video Gallery

Applications

CORiTEC 350i series Specifications

CORiTEC 350i PRO/Loader PRO |

CORiTEC 350i PRO+/Loader PRO+ |

||||

Spindle power |

1.0 kW | 3.6 kW (for PRO+ series) | |||

Spindle Technology |

Air Cooled, 2 Hybrid Bearings | Liquid Cooled, 3 Hybrid Bearings | |||

Motor Technology |

High-res Dynamic Servo with Absolute Encoder | High-res Dynamic Servo with Absolute Encoder | |||

Absolute Measuring System |

Yes | Yes | |||

Axis |

5 axis, simultaneous machining | 5 axis, simultaneously machining | |||

Angle of Rotation |

A-axis: 360°, B-axis: 115° | A-axis: 360°, B-axis: 115° | |||

Blank Capacity |

1 x Manual blank changer | 1 x Manual / Up to 12-fold automatic blank changer | |||

Blank Clamping System |

Zero Point (10 kN) | Zero Point (13 kN) | |||

Wet/Dry Processing |

Wet / Dry | Wet / Dry | |||

Blank Holder |

Aluminum | Stainless Steel | |||

Base Construction |

Steel & Polymerized Concrete | Steel & Polymerized Concrete | |||

On-board PC |

Windows based 15” Touchscreen | Windows based 15” Touchscreen | |||

Materials |

Chrome cobalt, titanium, zirconia, PMMA, acytal resins, PEEK, composites, wax, glass ceramics, sintered metal | Chrome cobalt, titanium, zirconia, PMMA, acytal resins, PEEK, composites, wax, glass ceramics, sintered metal | |||

Applications & Holders |

*only for CORiTEC PRO+ in preparation |

*only for CORiTEC PRO+ in preparation |