VHF N4+

vhf®

N4+ Dental Mill

The plus in wet grinding and milling

Enhance your dental clinic or laboratory's production value with the N4+ by vhf. It is an eye-catching dental mill in four axes with an integrated water-cooled spindle. This way, you get improved process stability, and even in continuous operation, you can always count on first-class results.

The Essence of Wet Grinding.

The N4+ is an efficient wet processing machine for grinding and milling glass ceramic, composite, and zircon blocks, as well as CoCr and titanium abutments. Thanks to its high precision, fast drives, and ultra-compact housing with a closed fluid circuit, it impresses. Eight fine nozzles on the spindle direct the cooling liquid precisely onto the effective area between the tools and the workpiece, delivering an optimal cooling effect.

Features

Proven Advantages of N4+

N4+ Technical Specifications

Field of Application |

Field of ApplicationWet Machining |

Base System Construction |

Base System ConstructionMachine bed made of solid cast aluminum body |

Housing |

HousingSheet steel housing, white high-gloss lacquer finish, with working chamber flap and cooling liquid tank integrated in the drawer |

Axes |

Axes

|

Control Unit |

Control Unit4-axis simultaneous control electronics with continuous path progression and dynamic pre-calculation · hardware-based real-time operating system with standardized command set · FPGA-integrated processor · updateable hardware · real-time path calculation via dedicated hardware engines in the FPGA · four-quadrant control of the motors for particularly smooth running · multiple analogue and digital I/Os for controlling the peripherals · integrated inverter for synchronous and asynchronous motors, electronic gate detection · Ethernet and USB interface |

Lighting & Camera |

Lighting & CameraRGB LED Lighting with status display | The camera system is integrated in the working chamber of the N4+ milling machine for easy remote support and the possibility of internal recording. |

Spindle |

Spindle

|

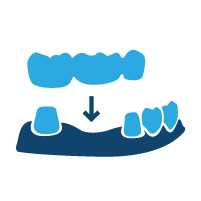

Tool Change |

Tool ChangeTool magazine for 8 tools, removable · length measurement and tool breakage monitoring via precision measuring key · access through working chamber door, safety lock |