VHF

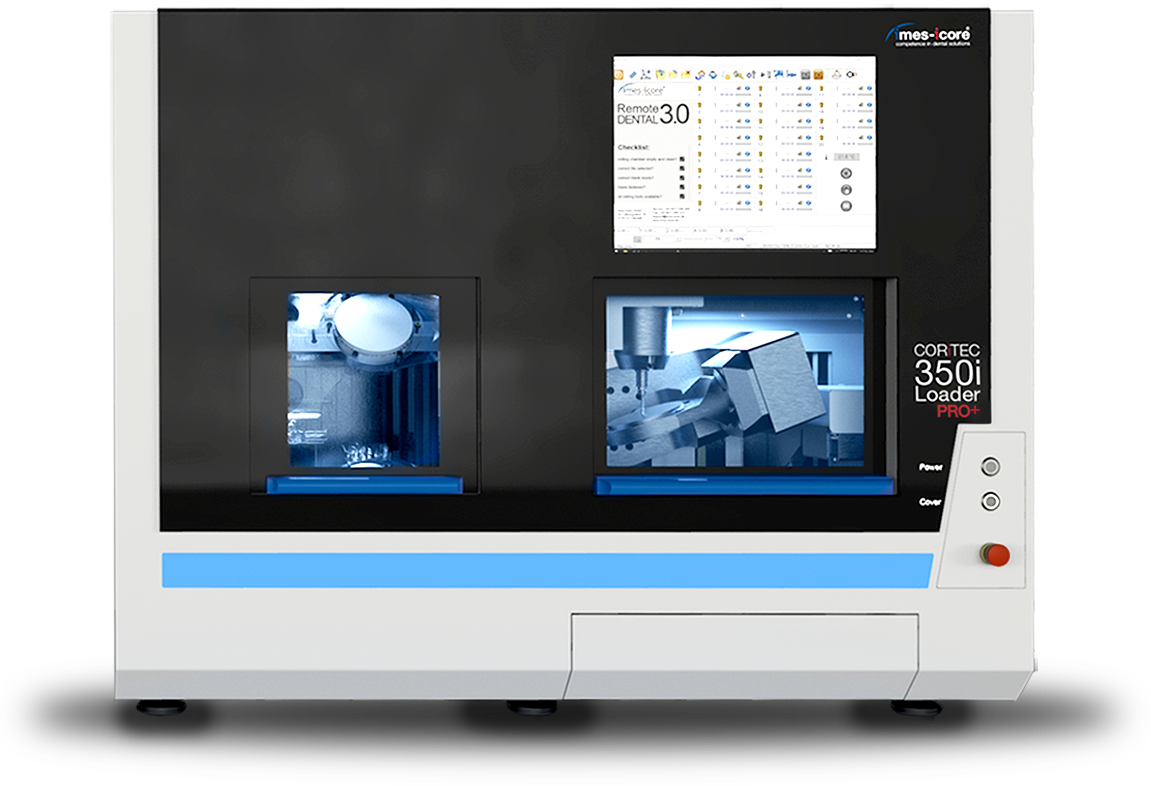

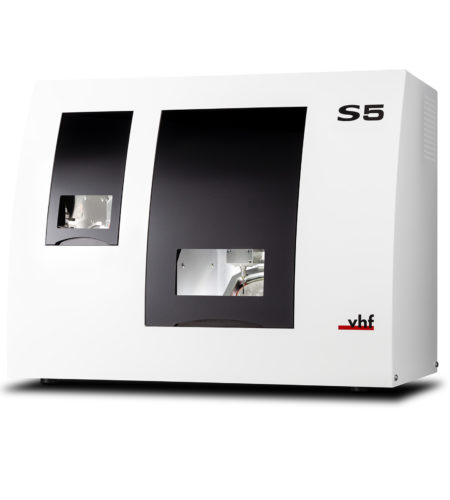

S5 Dental Mill

The affordable option for high throughput milling

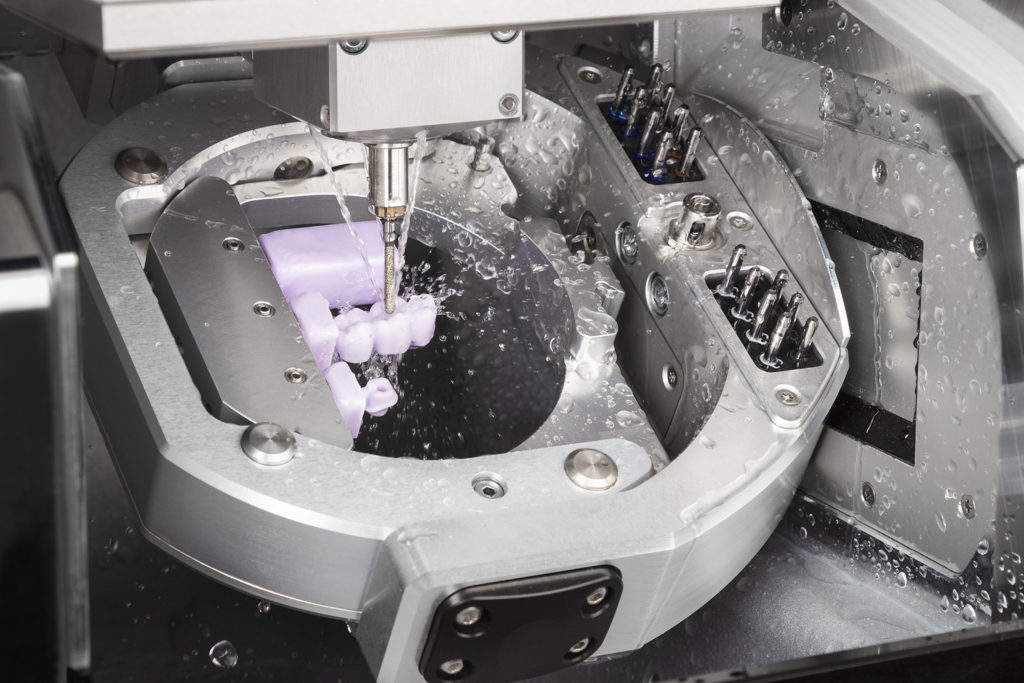

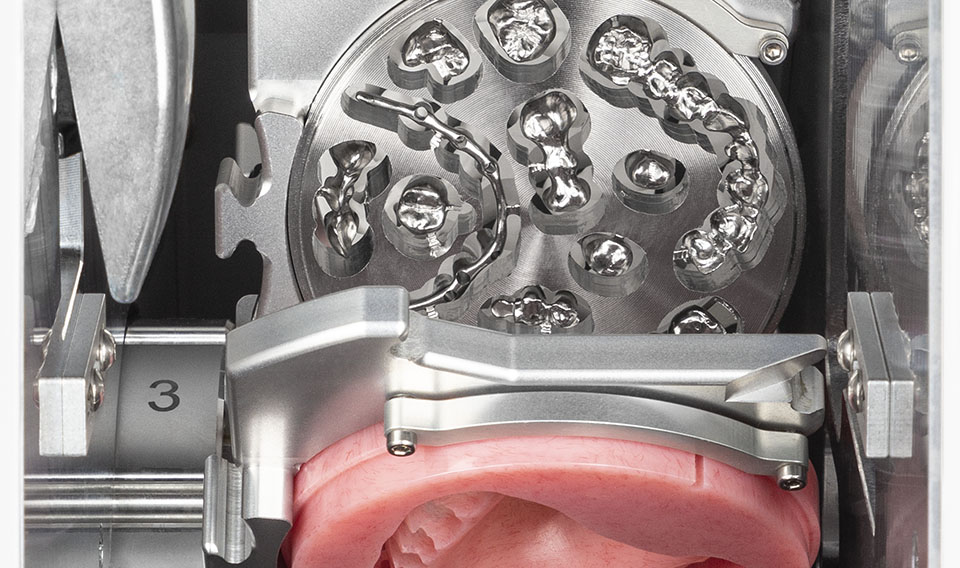

With five simultaneously working axes, a blank changer for 8 blanks, VHF's S5 is engineered for wet and dry machining. You can grind almost any type of glass-ceramics with the add-on wet grinding module. Whether your dental lab's milling and grinding needs are higher or lower, the S5 workhorse is undeniably the perfect solution.

5-axis machine gives you more freedom in milling

PRECISION is the fundamental prerequisite for every milling machine. Like any other VHF machine, S5 has the capability to mill beautiful restorations in ultra HD. The S5 has 5 simultaneously working axes and it is an open-system machine with almost unlimited material accessibility in 98 mm disc format, 38 different block materials and over 800 prefab titanium and cobalt chrome abutment blanks.

Key Features

Economical

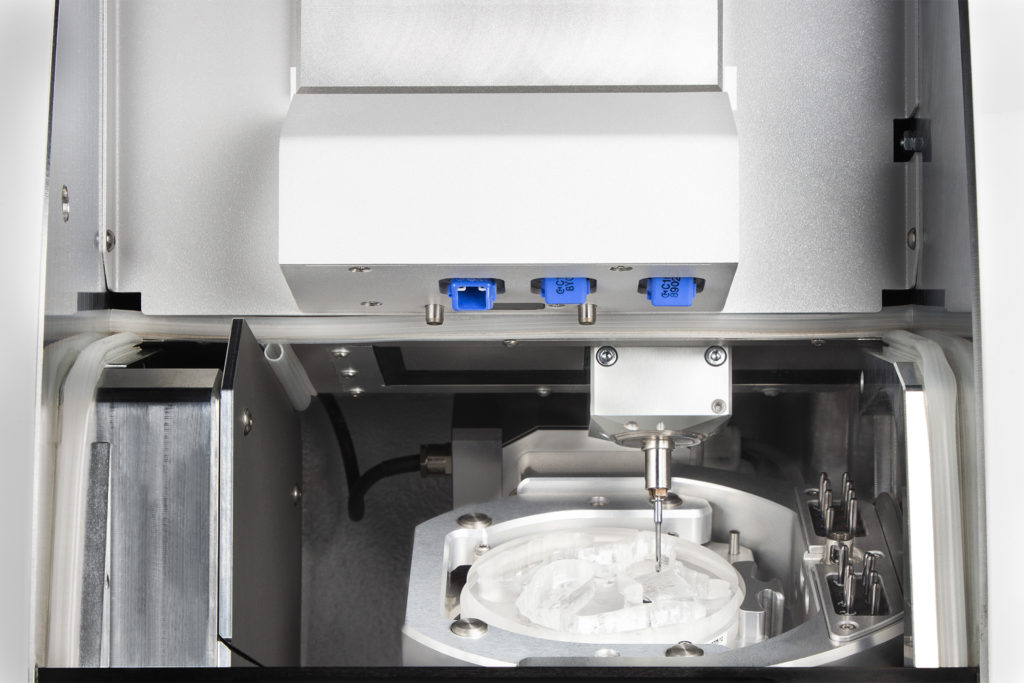

- Automatic changer for 8 discs, 24 blocks or 48 prefab abutments

- Automatic changer for 16 tools

- Three ionizers for a cleaner work chamber

- Quick frame magnetic changer

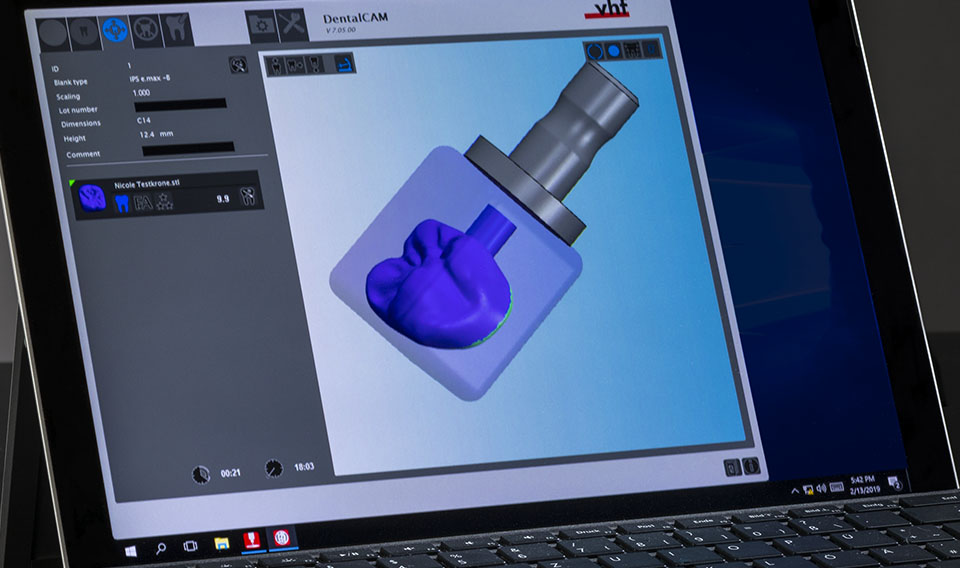

DENTALCAM software included with DIRECTMILL Technology

Open-source system

- Almost unlimited material compatibility with 98 mm disc format

- 38 different block materials

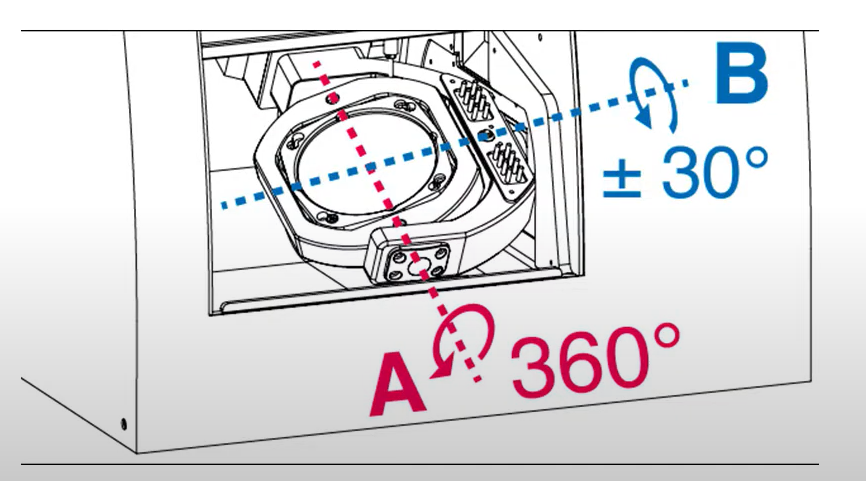

- Large indication diversity due to the ±30° rotation angle in the 5th axis

- Available wet grinding module as an add-on

Stability & Material Accessibility

- Solid cast-body for limited vibrations

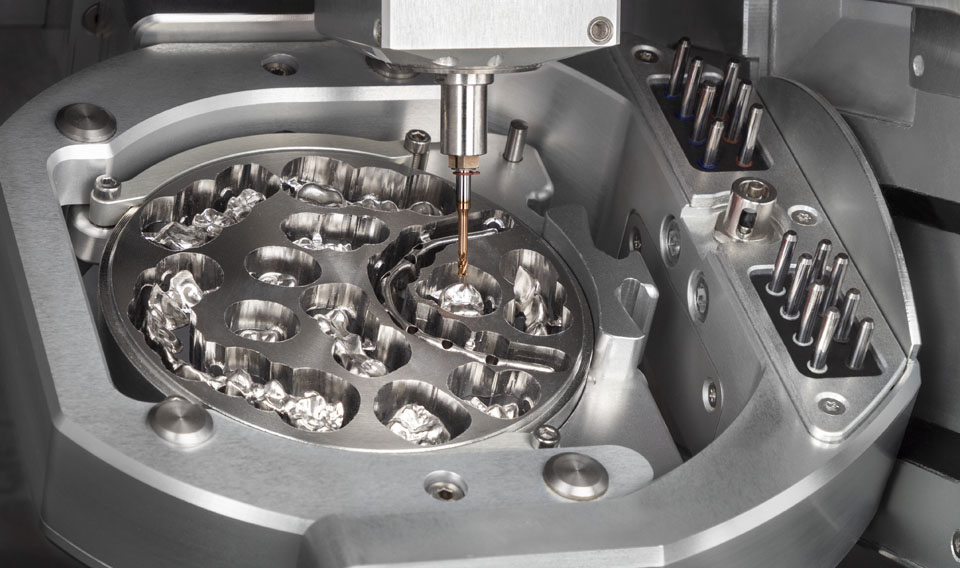

- Milling of any kind of materials including titanium (Ti), cobalt-chrome (CoCr) and Glass ceramics

Extreme Precision

- Restorations in HD

- Powerful spindle with 600 watts and 60.000 RPM

- 3 μm repetition accuracy

Reliability

- Non-stop performance with around the clock operation

- Designed and manufactured in Germany

- Two years warranty

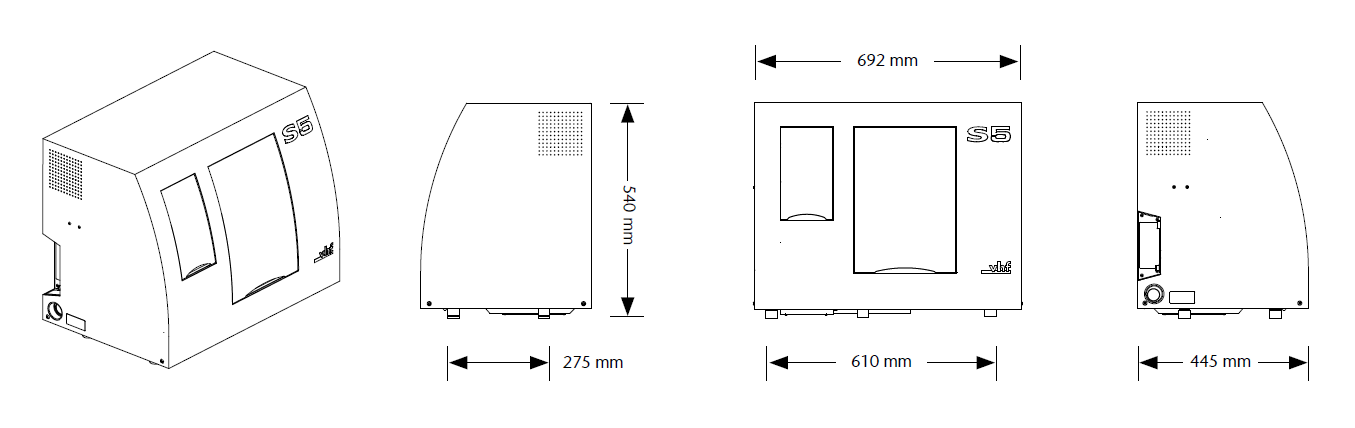

High performance on a small footprint

- Slick and modern look

- Table-top blank changer machine on a small footprint

- For higher or lower lab production

Key Highlights

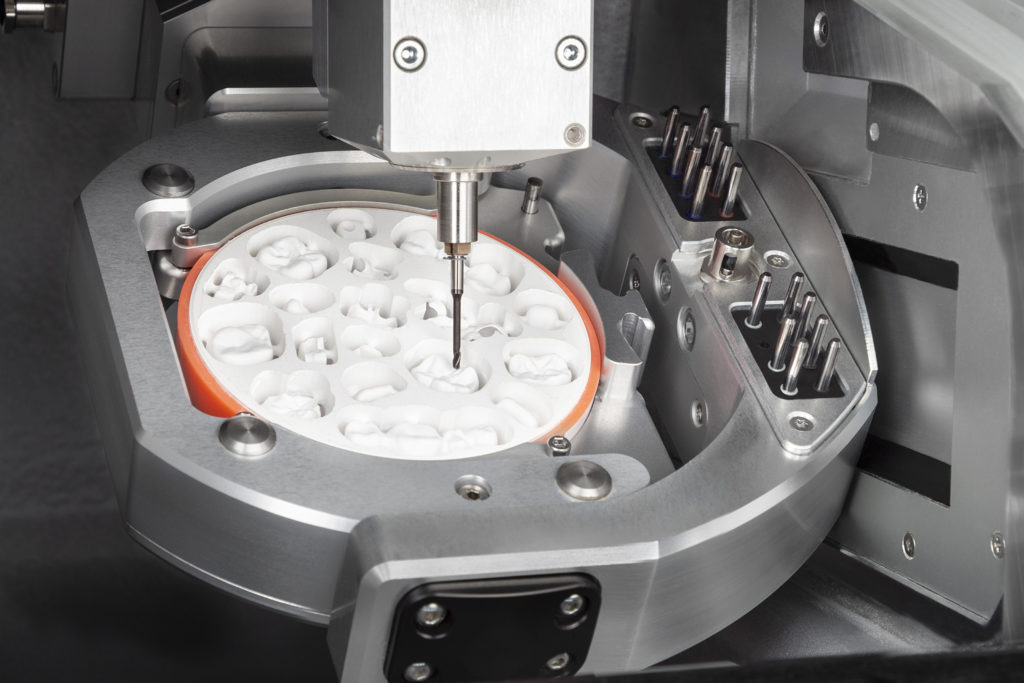

5-axis machine

S5 has five simultaneously working axes. While the fourth axis flips the length 360°, the fifth axis has a rotation angle of ±30° which makes it possible for additional freedom in milling. The milling tools can reach difficult areas thus having fewer undercuts to work manually, in particular for implant restorations or full arches.

Powerful spindle

The S5 has a German-made premium 600-watt spindle with 4-fold ceramic ball-bearings which guarantees the highest concentricity and smooth running. It allows the processing of metals and not only.

The wet-grinding module makes it possible for wet machining of glass ceramics or titanium.

Robust built

S5 achieves an astounding 3-micron repetition accuracy with a system of high-quality components directly mounted to a heavy and solid aluminum cast chassis.

This prevents vibrations and distortions so it can mill the toughest materials such as cobalt chrome, titanium, and glass ceramics.

In-house dental tools

VHF manufactures its own dental milling tools whether single or double tooth cutters, radius cutters or mounted points. This reduces the delivery times and a portfolio geared to the requirements of users. The dental milling cutters are made from a superfine grain carbide mixture from German production, characterized by high edge strength and outstanding wear resistance.

Quick magnetic frame

Traditionally, the frame for blank discs needs to be manually fixed with screws which is time-consuming. In addition, the risk of overtaking the screws leads to breaking the disc’s ring especially with the translucent zirconia, a super brittle material. The new magnetic quick frame is extremely convenient and fast: open-insert-close.

Benefits

Material flexibility

- Almost unlimited material accessibility in 98 mm diameter disc format

- 38 different block materials

- More than 800 prefab titanium and cobalt chrome abutment blanks

- up to 30 mm blanks

Exceptional accuracy

With the highly automated S5 milling and grinding machine that has an 8-station blank changer and a 16-position tool changer, you can have the lab production running around the clock. The repetition accuracy of 3 μm ensures first-class results for every workpiece, and the second rotary axis (B axis) with its tilt angle of up to ± 30 degrees also enables the precise milling of undercuts.

Integrated 3 ionizers

The versatile S5 has 3 integrated ionizers for easy machine cleaning, especially after a PMMA job. The static charge of the acrylic chips like the PMMA, is highly neutralized. The ionized air is distributed by the air nozzles in the working chamber, therefore less time spent on cleaning.

CAM software with DIRECTMIL

S5 comes with DENTALCAM software with DIRECTMIL Technology therefore no license fees are required. Typically a machine does not start until the calculation of the tool path is completed. For faster milling, due to DIRECTMIL the S5 starts working and it keeps milling while the calculation is being finished.

Wet Grinding Module

You can add at a later date the wet grinding option if your dental lab or clinic requires it. This module consists of an 11-liter water tank, a pump for the water to circulate and a sophisticated triple filter system. The water level is monitored by an ultrasonic sensor and the status is shown on the display in different colours.

Economical & Convenient

- Material accessibility

- 5-axis simultaneously working

- Automatic changer for 8 discs, 24 blocks or 48 prefabricated abutments

- Automatic changer for 16 tools

- 3 ionizers

- Quick frame magnetic holder for easy, tool-free clamping of discs

Materials

Zirconia

Titanium

Cobalt Chrome

WAX / Plastics

Composites

Glass ceramics

Applications

Technical Specifications

Base System |

Base System

|

Spindle |

Spindle

|

Connection Requirements |

Connection Requirements

|