KeyPrint® KeyOrtho IBT™

KEYSTONE INDUSTRIES

KeyPrint® KeyOrtho IBT™

Manufacture highly-precise indirect bonding trays

With KeyOrtho IBT™ biocompatible photomolymer resin from Keystone Industries you can have less chair time and improve the patient's comfort during the orthodontic bracket setting process.

Accurately Set Brackets with Strong and Precise IBTs

KeyOrtho IBT™ is ideal for printing orthodontic transfer trays for positioning brackets. KeyOrtho IBT’s translucency allows for precise positioning before and during bracket placement. Its high tensile strength allows for easy application of brackets in a single step, reducing chair time to minutes. It is flexible for easy removal and works with all general bracket systems. It is also odorless and tasteless for patient comfort.

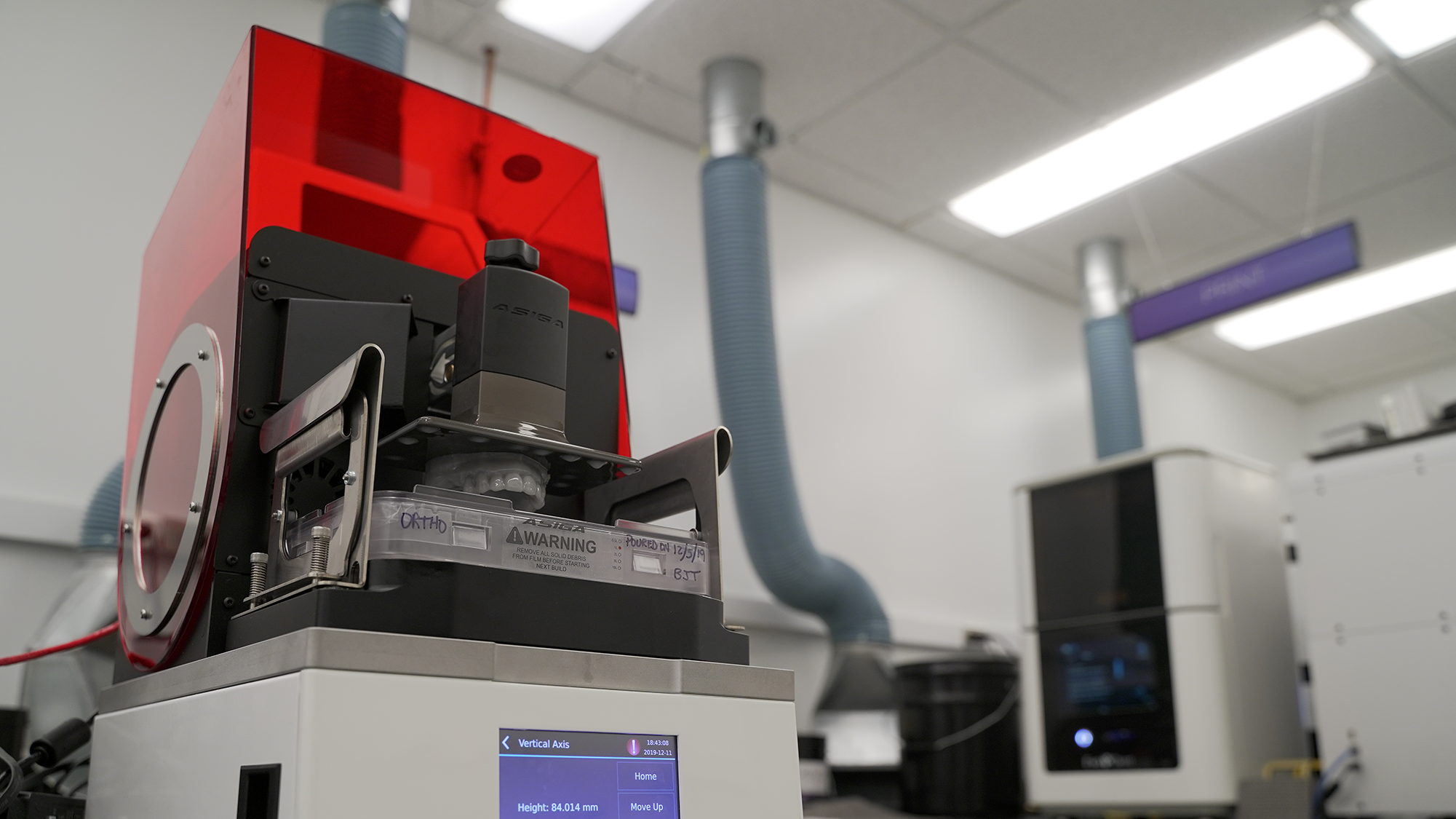

This liquid photopolymer 3D printing resin is designed for additive manufacturing in vat Polymerization DLP printers utilizing wavelengths between 385 nm–405 nm. Characterized by its flexibility, elongation at break, and adhesive release from dental cement, KeyOrtho IBT™ is the optimal material for 3D printing Indirect Bonding Trays.

Features

Find the right material for your dental application.

Specifications

| Tested property | Standard method | Result |

| Tensile Strength | ASTM D638 | 8.0 – 10.5 MPa |

| Tensile Modulus | ASTM D638 | 15.5 – 31.0 MPa |

| Elongation at Break | ASTM D638 | > 130% |

| Free Monomer Extraction | ISO 20795-2 | < 2.2% |

| Cytotoxicity | ISO 10993 | PASS |

| Orthodontic Adhesive Release | Internal | PASS |

*Denotes Keystone determined passing criteria based on design requirements