PostProcess® AUX-400-RINSE

PostProcess® AUX-400-RINSE Technical Spec Sheet

Read More

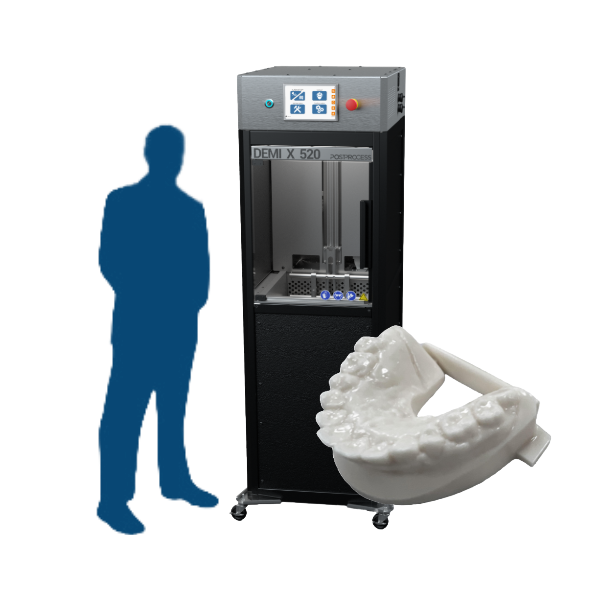

PostProcess® DEMI X 520 is a complete and automated resin removal system for 3D-printed dental parts & devices that comes with integrated custom AUTOMAT3D software, an adjustable build platform fixture with Catch Tray and is IPA-free. This system works with biocompatible detergents such as PLM-403-SUB in combination with a rinsing solution, AUX-400-RINSE, so that you can ensure productivity in a safe lab-environment.

Thanks to the innovative Axis Flow Technology and patented chemistry with biocompatible and environmentally friendly detergents, you’ll have a seamless, efficient, error-free post-processing operation. DEMI X 520 eliminates time-consuming and expensive piece-by-piece manual cleaning.

The DEMI X 520 for Dental Resin Removal Solution features a combination of PLM-403-SUB detergent used in the hardware, followed by a rinse step with AUX-400-RINSE* in a separate container.

*Biocompatibility testing has not yet been completed for AUX-400-RINSE.

PostProcess® AUX-400-RINSE Technical Spec Sheet

Read MoreApplication Note | Chemistry Advancements for Automated Resin Removal PLM-403-SUB

Read MorePostProcess® Proprietary Detergents used according to the 3D printing technology type.

Read More

Size and Weight |

Size and WeightEnvelope

Machine Footprint

Approx. Weight

|

Electrical | US |

Electrical | USPower: 120V, 60HzConnector: NEMA 5-15P Axial agitation; includes heater |

Safety |

Safety

|