VHF E3

vhf®

E3

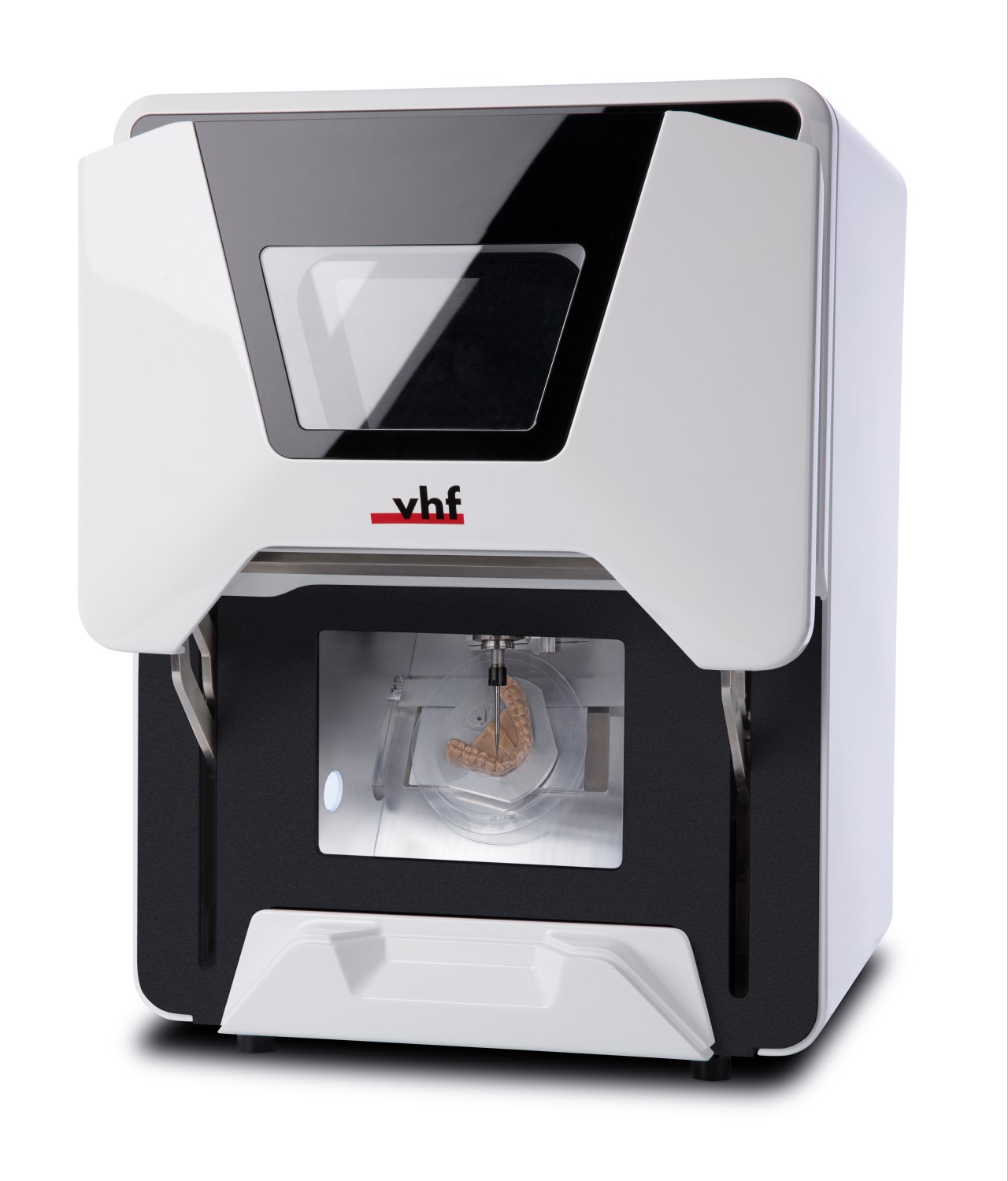

The milling machine for orthodontic applications

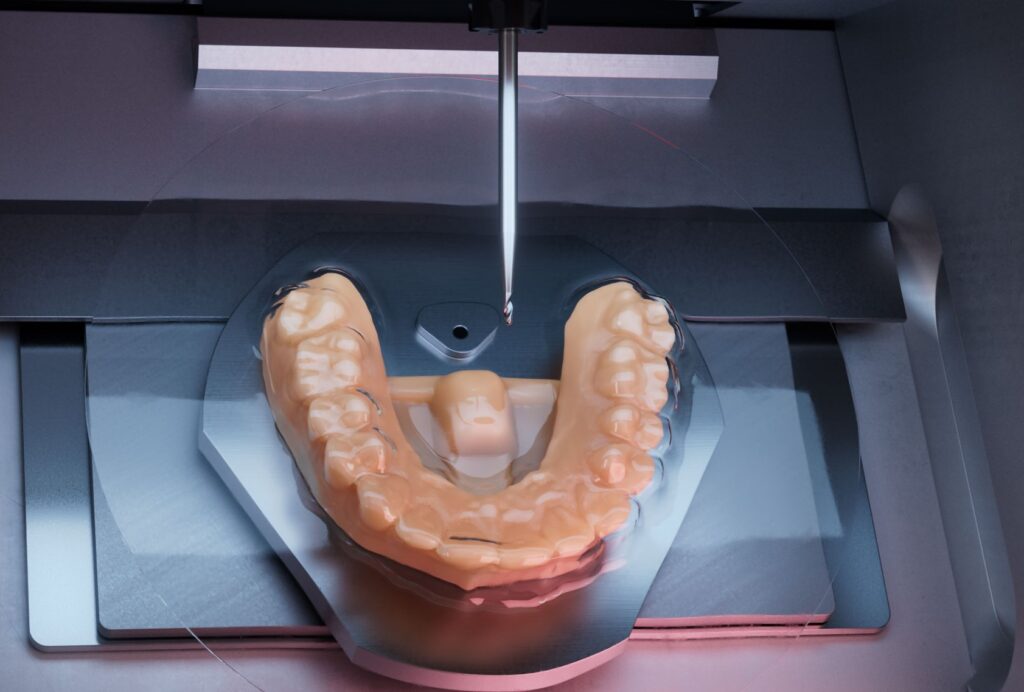

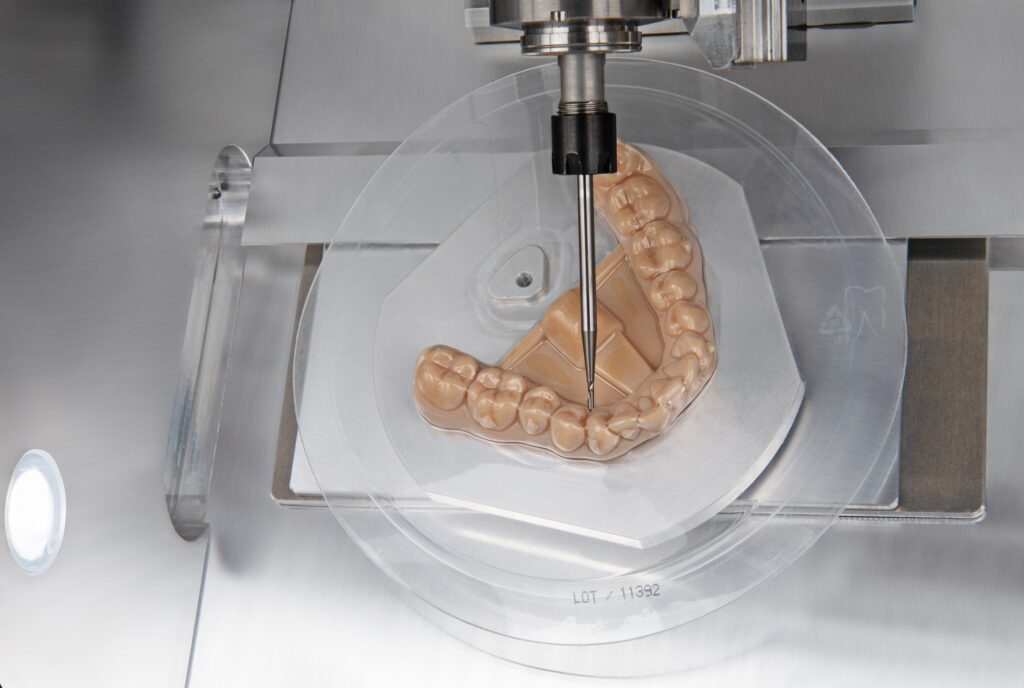

E3 is vhf®'s specialist for the processing of occlusal appliances. It helps dental professionals to automate the precision of trimming the occlusal appliances such as aligners, bite splints, grinding splints and other variants up to sports mouth guards.

Features

E3. Cut Out Occlusal Appliances @ Low Production Costs

Fast, Reliable and Affordable process

No Manual Labour.

vhf® E3 is the first machine for an automated cutting process of thermoformed splints, such as aligners, bite splints, grinding splints or sports mouthguards. Until now, this process was manually done. Not anymore.

Aligner and Splint Production | Easier than Ever

Thanks to its compact size, the E3 doesn’t require compressed air connection, therefore, it offers great flexibility in terms of installation site. In addition, no other extraction system is required, as this German-engineered milling machine was designed with a practical collection tray for chips.

Machine Aligners in 45 to max. 60 Seconds

Despite its compact design, E3 offers you CNC production high-precision accuracy and speed. For example, an aligner can be milled out in less than 60 seconds (45” in average).

vhf’s E3 is a tool-free clamping system built to ease your work and save you time in your entire series of aligners production. Besides aligners, this machine is also recommended for all sorts of occlusal appliances such as bite splints, grinding splints and other splints, including sports mouth guards.

TRIMCAM 1.4 with Open Interface to Planning Software

Technical Specifications

General Specs |

General Specs

|

Base System |

Base System

|

Spindle |

Spindle

|

Connection Requirements |

Connection Requirements

|

Environmental Conditions |

Environmental Conditions

|

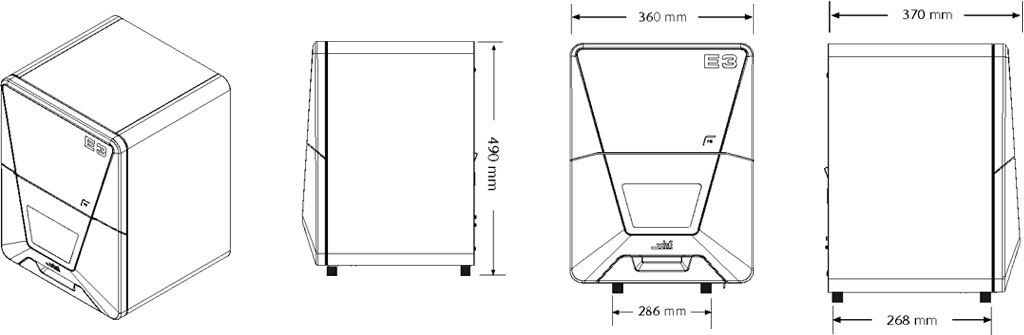

Dimensions & Weights |

Dimensions & Weights

|

Scope of Delivery |

Scope of DeliveryCAM Software | TRIMCAM software for aligner production included in the scope of delivery |

Accessories |

Accessories

|