Dekema Dental Furnaces

DEKEMA®

DEKEMA® DENTAL FURNACES

Maximum performance and consistent quality results

The DEKEMA® family of AUSTROMATs dental ceramic furnaces has a unique firing chamber concept with an intuitive user interface and functionality so that every ceramic restoration is a work of art that approximates nature as closely as possible.

Fire it up with Dekema® dental furnaces!

Produce zirconia restorations safer, easier and more accurate

The Dekema® furnaces work based on an innovative sintering technique for the modern digital workflow. They’re easy to use, small in size and they preserve the quality and the performance of the processed zirconia.

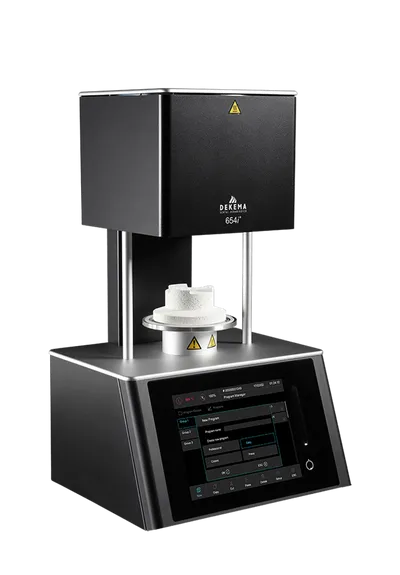

Dekema® AUSTROMAT™ Series 6

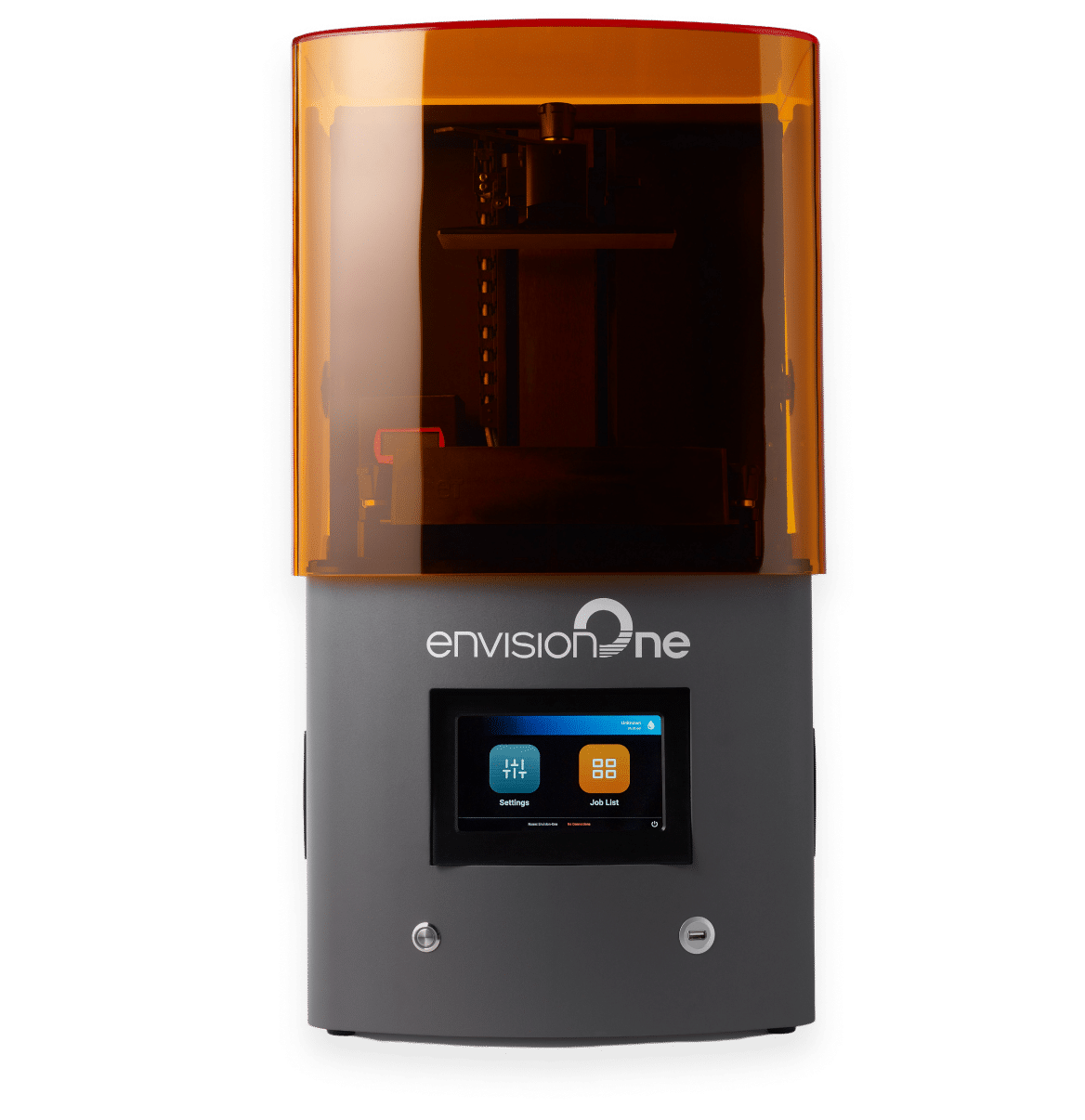

Dekema® AUSTROMAT™ 624

For Firing Dental Ceramics

The proven firing chamber concept assures excellent firing results within all temperature ranges. The combination of the intuitive user interface and internet-capable electronics ideally adapts to the practical needs of the modern dental technician. The focus is readjusted on the dental technician’s daily work.

Full Description

The AUSTROMAT 624 is operated through a high-resolution touch screen. Different data in and output possibilities, as well as several program editing functions perfectly adapt to the individual requirements of any dental technician. You can start one of the 200 active programs just by pushing one button. The program may be changed during operation, optionally even remotely over the network. In the background, you may store a more or less unlimited quantity of programs inside the furnace’s database.

Specs

-

- Size (H x W x D): 653 x 383 x 343 mm³

- Weight: 17,5 kg

- Power Supply: 230 V / 50 to 60 Hz

- Max. Power Consumption: 1,5 kW

- Tmax: 1200ºC

- Touch Screen: 7,5″, color

- Programming languages:

- Easy

- Professional

- Classic

- Dekema Vacuum Pump: Available

- Dekema AUTODRY: Available

- Housing: Anodized Aluminum

Dekema® AUSTROMAT™ 644

Combi Furnace for Firing & Pressing with One or Multi-Plunger-Ring-Systems

The reliable firing furnace expanded to a combi furnace for firing and pressing. Fire your dental restorations as usual. Press with the patented vacuum pressing system. It works independently of an external compressed air supply. It perfectly suits to excellent pressings a one-plunger ring system.

Full Description

Ambient pressure is cleverly exploited to reliably press with the AUSTROMAT 644. This patented, high-resolution process even allows controlled pressings at different, pre-defined press forces. Standard ring systems of any press ceramics’ supplier with diameters up to 70 mm and total heights up to 88 mm can be processed under vacuum inside the pressing chamber.

Specs

- Size (H x W x D): 757 x 383 x 343 mm³

- Weight: 18,5 kg

- Power Supply: 230 V / 50 to 60 Hz

- Max. Power Consumption: 1,5 kW

- Tmax: 1200ºC

- Touch Screen: 7,5″, color

- Programming languages:

- Easy

- Professional

- Classic

- Dekema Vacuum Pump: Available

- Dekema AUTODRY: Available

- Housing: Anodized Aluminum

Dekema® AUSTROMAT™ 654

654 press-i-dent Combi Furnace for Firing & Pressing with One or Multi-Plunger-Ring-Systems

The Austromat 654 is equipped with innovative, controlled, electro-mechanical upwards-pressing propulsion. It also has a closed firing chamber, no hole on top therefore no cold spots thus delivering the homogeneous temperature distribution, needed to perfectly fire every layered dental restoration.

Full Description

- Pressing several colours/ingots with multiple plungers in one ring

- Press without vacuum

- Quick cooling steps during pressing

- Firing high and low fusion dental ceramics towards the highest customer satisfaction.

Specs

- Size (H x W x D): 653 x 383 x 343 mm³

- Weight: 22 kg

- Power Supply: 230 V / 50 to 60 Hz

- Max. Power Consumption: 1,5 kW

- Tmax: 1200ºC

- Touch Screen: 7,5″, color

- Programming languages:

- Easy

- Professional

- Classic

- Dekema Vacuum Pump: Available

- Dekema AUTODRY: Available

- Housing: Anodized Aluminum

Dekema® AUSTROMAT™ 664

For sintering copings up to 1.530°C

DEKEMA®’s specific SiC (Silicon carbide) heating technology makes it possible to merge user-oriented operation, short sintering cycles, low energy consumption and a very small footprint. Approx. 40 copings or restorations with up to 6 units can be reliably sintered in one cycle with up to 1.530°C.

Full Description

The high-temperature furnace AUSTROMAT 664 is equipped with two silicon carbide heating elements to safely and consistently operate at temperatures up to 1.530°C. All the components of the AUSTROMAT 664 sintering chamber are made of the highest purity, durable materials to ensure very homogeneous heat distribution in a clean atmosphere.

A patent-pending, DEKEMA specific Platinum/Platinum Rhodium thermocouple monitors the temperature inside the sintering chamber. Approximately 20 copings with a max diameter of 65 mm may be simultaneously sintered on top of the patented insulation table, optionally in two levels doubling capacity. The AUTODRY feature provides precise drying steps and quick and direct heating and cooling steps for extremely short sintering cycles.

Specs

- Size (H x W x D): 780 x 383 x 343 mm³

- Weight: 21 kg

- Power Supply: 230 V / 50 to 60 Hz

- Max. Power Consumption: 2 kW

- Tmax:

- 1530ºC

- 1560ºC (optional)

- Touch Screen: 7,5″, color

- Programming languages:

- Classic

- Dekema Vacuum Pump: Available

- Dekema AUTODRY: Available

- Housing: Anodized Aluminum

Dekema® AUSTROMAT™ 674

For sintering copings up to 100 mm in diameter

Three heating elements realize a homogeneous temperature distribution up to as high as 1.530°C. Remote control and quality management are optionally integrated and provide a reliable partner for your milling or grinding machine. QR Scanning is available with this model.

Full Description

The AUSTROMAT 674 is equipped with three silicon carbide heating elements, perfectly fitting for sintering at temperatures up to 1.530 °C. These heating elements feature robustness and durability and won’t discolour copings.

The firing chamber is closed through the vibration-free lift system.

Each sintering level has a capacity of 40 sintering units. You can equip the furnace with 2 levels to reach the highest throughput. The diameters of sintering goods may reach up to 100 mm.

Specs

- Size (H x W x D): 780 x 383 x 343 mm³

- Weight: 24 kg

- Power Supply: 230 V / 50 to 60 Hz

- Max. Power Consumption: 2 kW

- Tmax:

- 1530ºC

- 1560ºC (optional)

- Touch Screen: 7,5″, color

- Programming languages:

- Classic

- Dekema Vacuum Pump: Available

- Dekema AUTODRY: Available

- Housing: Anodized Aluminum

Dekema® AUSTROMAT™ Series i

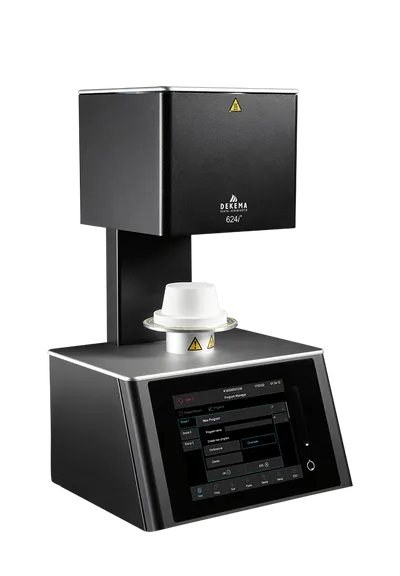

Dekema® AUSTROMAT™ 624i

Overview

- Firing Furnace up to 1200°C

- Fire & Glaze with and without Vacuum

- Crystallize & Infiltrate with and without Vacuum

Dekema® AUSTROMAT™ 654i

Overview

- Combi Furnace up to 1200°C

- Press, Fire & Glaze with and without Vacuum

- Crystallize & Infiltrate with and without Vacuum

- Press several Plungers/Colors in one go with the optional Trixpress™

Dekema® AUSTROMAT™ 664i

Overview

- High-Temperature Furnace up to 1560°C

- Sinter, Glaze & Crystallize under Atmosphere

- Chairside Speed Mode Space for up to six-unit bridges or up to 20 units in one level (Ø 65mm)

Dekema® AUSTROMAT™ 674i

Overview

- High-Temperature Furnace up to 1560°C

- Sinter, Glaze & Crystallize under Atmosphere

- Chairside Speed Mode Space for all common bridge sizes or up to 40 units in one level (Ø 100mm)

The uniqueness of Dekema furnaces

Platinum-Rhodium thermocouple for a controlled temperature up to 0.1 centigrade (°C) at 1500ºC

The major challenge with dental furnaces comes from an unstable temperature that can lead to the pollution of the zirconium. In other words, you can end up with the discoloration of the zirconium.

The Dekema furnaces have Platinum-Rhodium thermocouples that make it possible to have an outstanding temperature calibration, with unmatched precision.

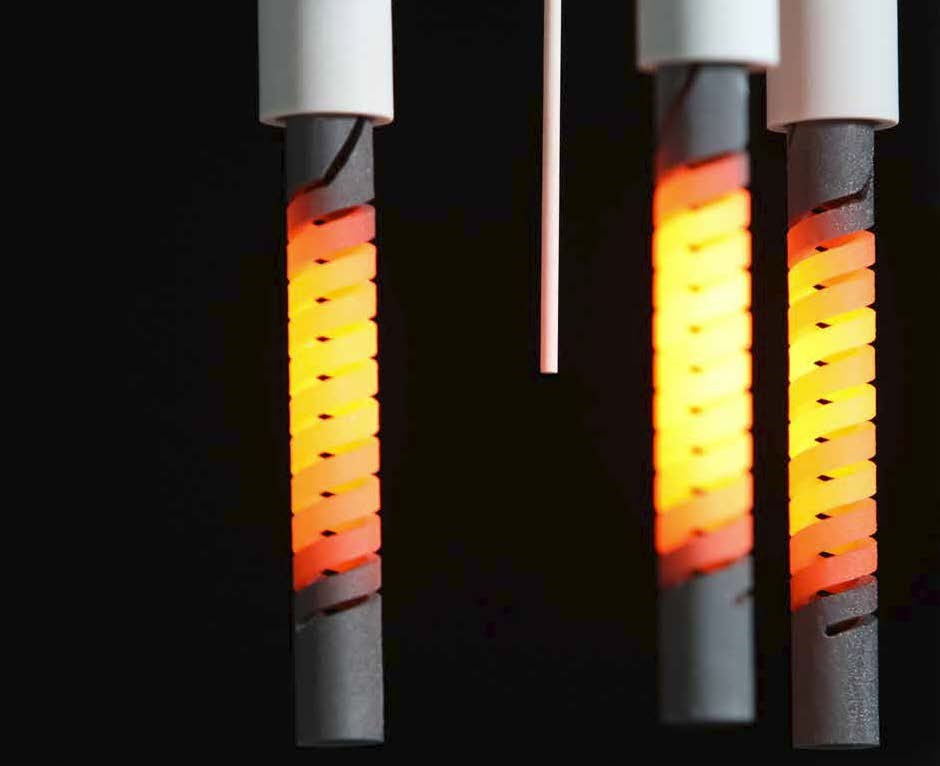

Patented Thermal Elements

The Dekema furnaces are equipped with heating elements made from recrystallized silicon carbide that are permanently self-cleaning. This means that no pollution inside the thermocouple is permitted, thus maintaining unpolluted zirconium.

Plug & Play. Easy to Use

Dekema’s AUSTROMAT series of furnaces are extremely easy to use, with a friendly and intuitive user interface. They have a language-independent icon surface, a touch operation with 100 programs and an independent vacuum start.

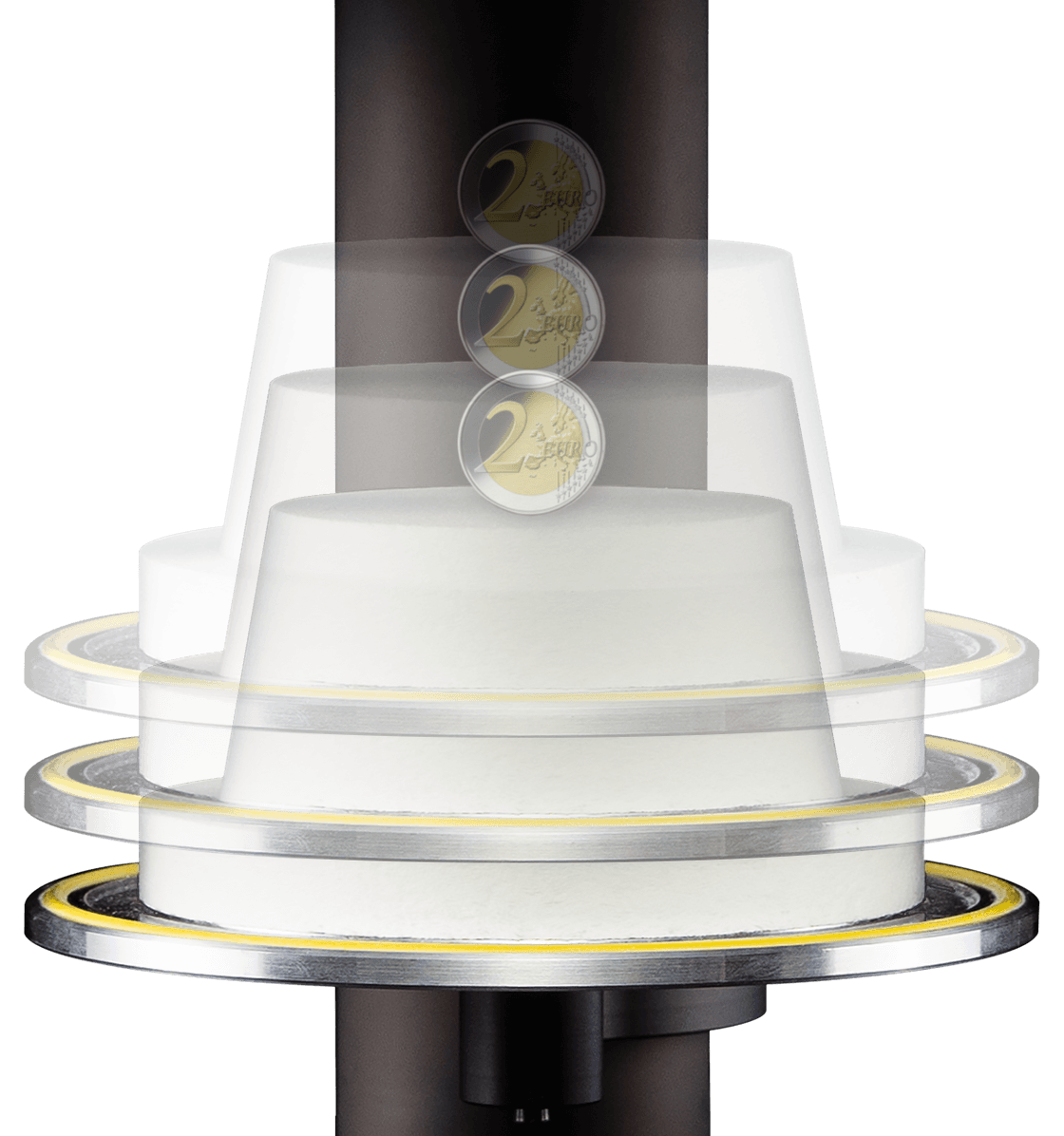

Dekema Autodry & Lift System

AUTODRY simulates the object temperature and automatically regulates the distance between the firing object and the firing chamber with the vibration-free lift for precise and accelerated drying, heating and cooling phases. The lift system is made of durable stainless steel.

QR Reader*

You can program a cycle with just one click. QR codes are freely provided on the Dekema internet database. Cycles can also be started temporarily. Associated information such as operator, program, program parameters, times, are stored inside the internal quality management module of the furnace.

*Available with the series 6 products.

Dekema Database – Load & Start

Access thousands of firing, pressing and sintering programs from dental ceramics manufacturers that are saved and maintained in the Dekema database. You can stream more than 60,000 programs.