VHF E5

vhf®

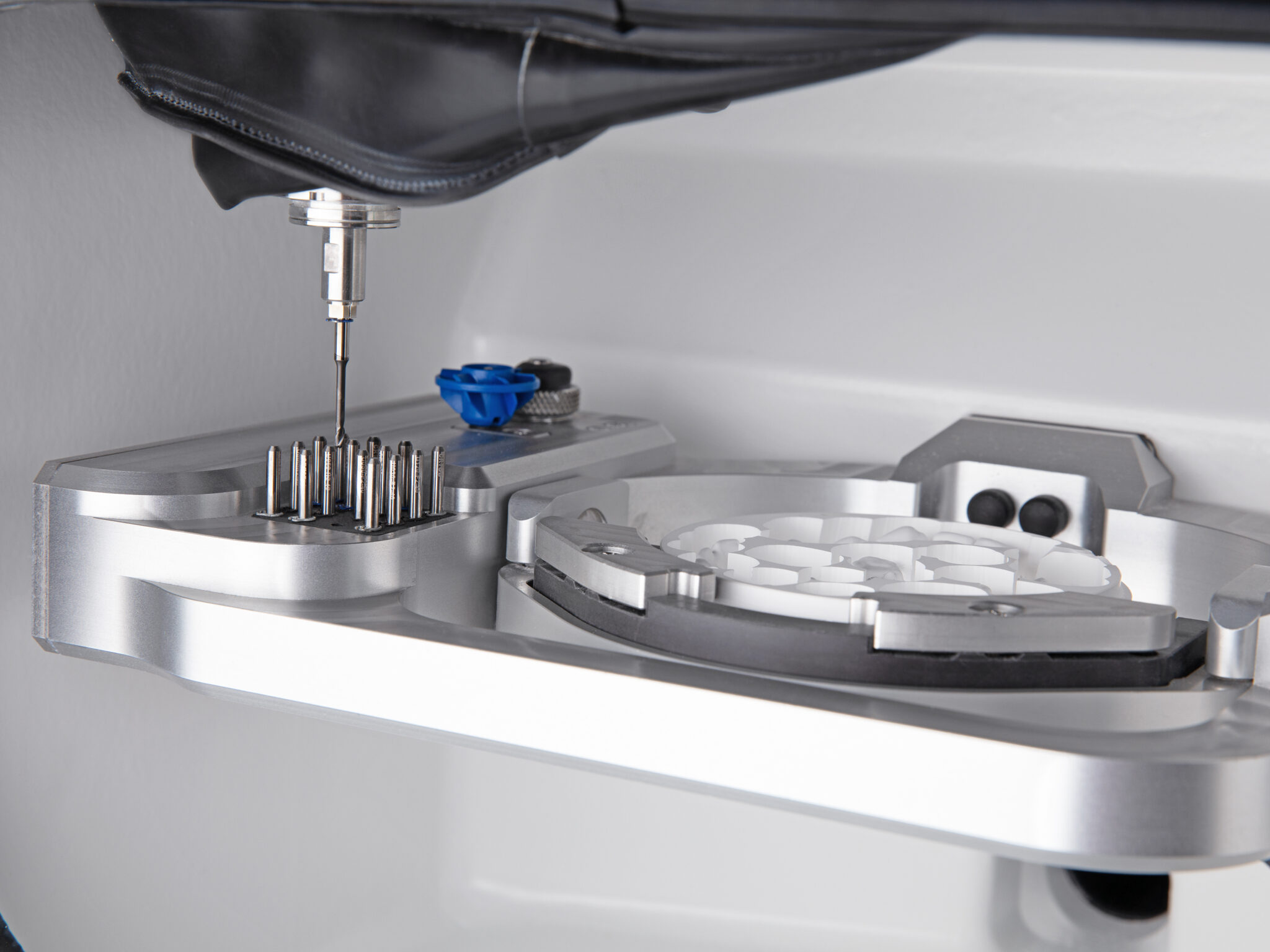

E5 Dental Mill

Premium dental milling made easy

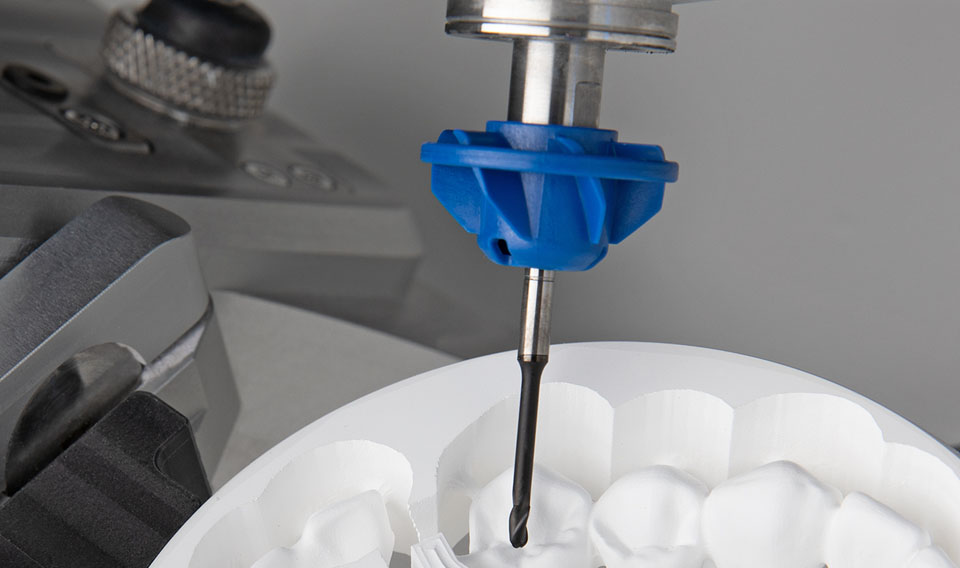

Introducing the vhf E5 dental milling machine - the ultimate solution for efficient and precise dental restoration production. With vhf's state-of-the-art technology, the E5 boasts a unique patent-pending AIRTOOL that generates a powerful airflow without the need for compressed air or an integrated compressor. The E5's intuitive interface and simple operation ensure a smooth and hassle-free experience for dental technicians of all levels. With its compact design and powerful performance, the E5 is the perfect addition to any dental laboratory looking to maximize efficiency and productivity. Trust the vhf E5 to deliver outstanding results with every restoration job.

Plug & Mill: Unpack, Connect, Start Milling!

vhf’s E5 was designed for maximum flexibility and ease of operation. With no compressed air required, installation can happen almost anywhere, with minimal operational costs. E5’s open system architecture makes it possible for you to produce dental restorations quickly and easily, all while integrating into your current digital workflows.

E5. Five stars dental mill:

★ 5-axes

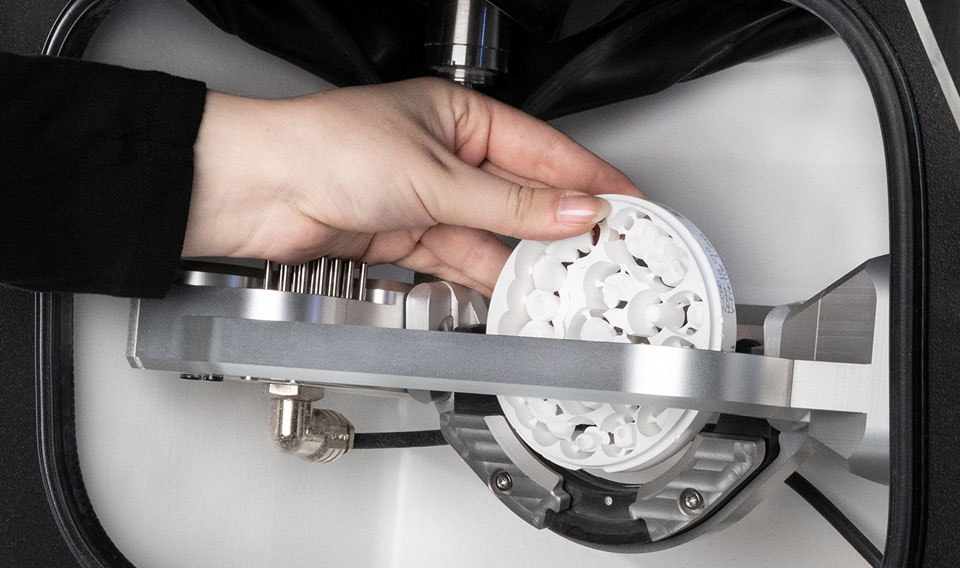

★ one disc

★ 6 blocks

★ 17 tools

★ An integrated CAM software

Features

Discs, Blocks, or Abutments.

Material freedom.

Applications

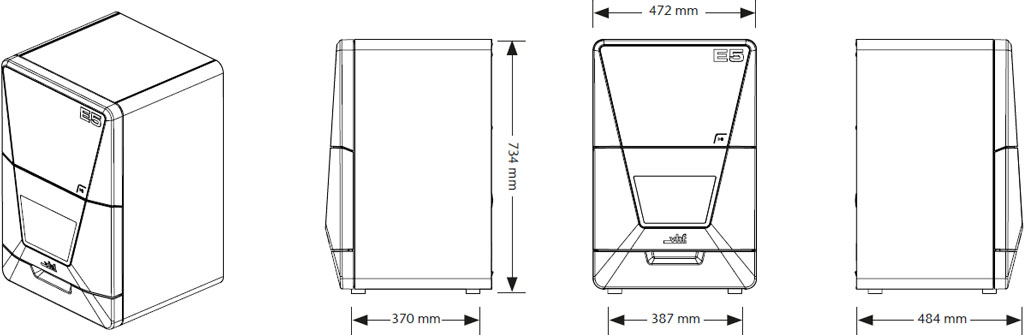

Technical Specifications

Construction |

ConstructionMachine bed made of solid cast aluminum body |

Housing |

HousingWhite high-gloss lacquer finish - upward opening lift door to the workroom |

Number of Axes |

Number of Axes5 (five) |

Linear Axes X-/Y-/Z-axis |

Linear Axes X-/Y-/Z-axis

|

Rotary Axis B-axis |

Rotary Axis B-axisBacklash-free tension shaft gear with highest angular accuracy · rotation angle: 360°, infinite |

Control Unit |

Control Unit

|

Lighting |

LightingRGB LED lightining with status indication |

Spindle Speed |

Spindle SpeedUp to 60,000 rpm |

Power |

Power

|

Bearing |

Bearing2-fold hybrid ceramic ball bearing |

Collet |

ColletFor tools with 3 mm shank diameter and max. 40 mm total length |

Tool Change |

Tool Change

|

Processing Modes |

Processing ModesDRY

|

Connection Requirements |

Connection RequirementsCompressed air - Not requiredPower Supply: 100 - 240 volts; 50/60 Hz, 500 watts Extraction System: Extraction filter class M, 2,500 l/min extraction capacity at 200 hPa Data: 10/100/1000 MBit/s BaseT port (auto-sensing) Ethernet via RJ-45 socket |

Operating Temperature |

Operating TemperatureBetween 10°C and 35°CAir Moisture: Max 80% (relative), non-condensing |