PostProcess Technologies® Chemistry Overview

PostProcess® Proprietary Detergents used according to the 3D printing technology type.

Read More

PostProcess® Technologies

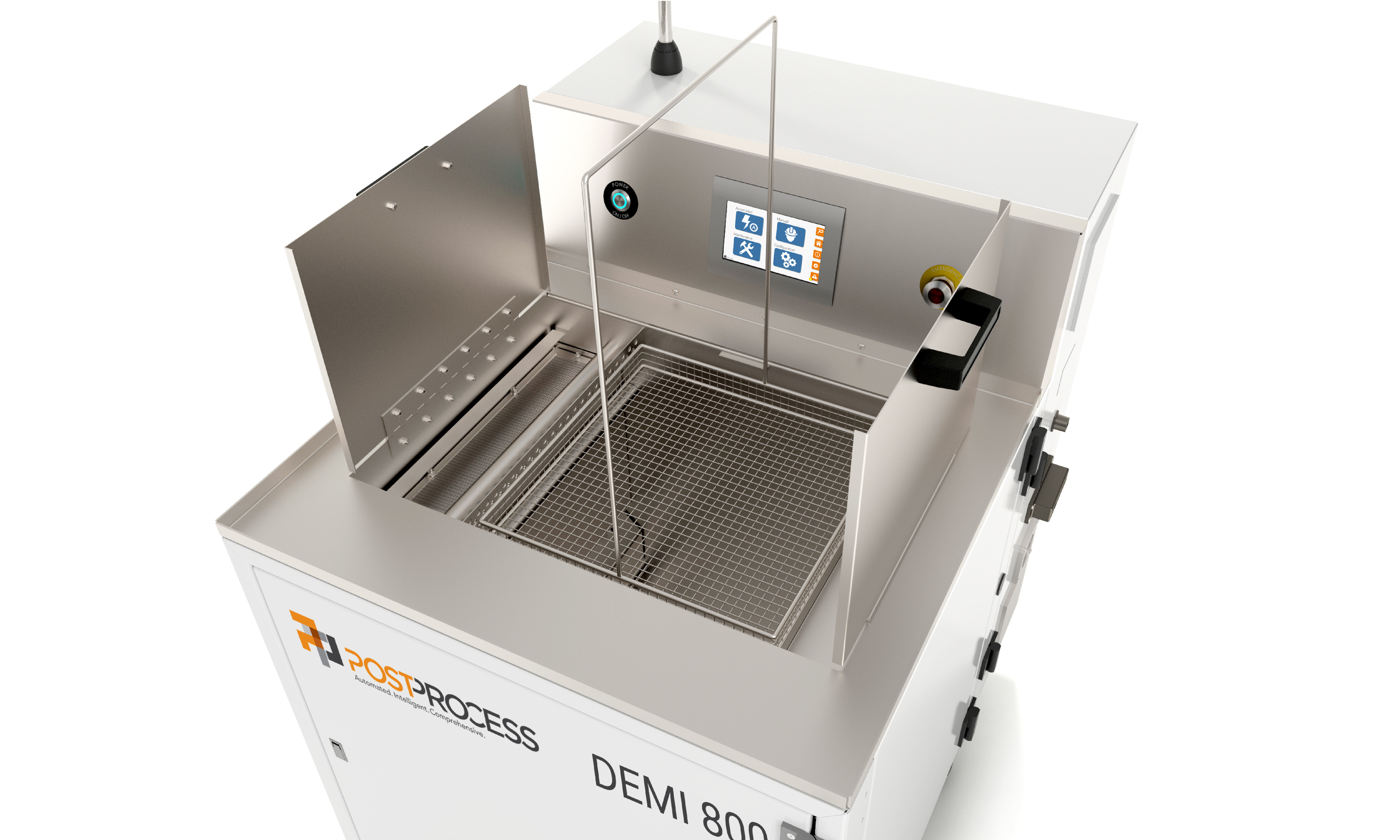

The DEMI 800 Series uses PostProcess' Submersed Vortex Cavitation (SVC) technology for removing 3D-printed supports or the excess of resin after the additive manufacturing process. The DEMI systems are compatible with various 3D-printing technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), PolyJet, CLIP or Digital Light Processing (DLP). It is available in a variety of models based on your unique application needs.

No matter the 3D-printing technology, whether it’s FDM, PolyJet, SLA, DLP, or CLIP, you can enhance your additive manufacturing efficiency with the PostProcess™ DEMI 800, an automated support and resin removal solution crafted for high throughput and consistency across every part. With integrated patented software and exclusive chemistry technologies, the DEMI 800 automates post-printing processes, delivering remarkable reductions in cycle times.

Moreover, all PostProcess hardware solutions have been developed to use special additive-formulated detergents compliant with ISO standards for biocompatibility, not IPA (isopropyl alcohol).

PostProcess® Proprietary Detergents used according to the 3D printing technology type.

Read MoreOverview of automated, digitized post-processing solutions for Additive Manufacturing

Read More

AUTOMAT3D® Software Features |

AUTOMAT3D® Software Features

|

Hardware Features |

Hardware Features

|

Size and Weight |

Size and Weight

|

Detergent |

Detergent

*NOTE: Implement an IPA-free resin removal workflow with AUX-400-RINSE as the final rinse step.: Rinse step is to be performed in separate container, not to be used in PostProcess hardware |

Electrical |

ElectricalDEMI 800 Model (SLA/DLP/CLIP only)

DEMI 830-120V Model (PolyJet/FDM/SLA/DLP/CLIP)

DEMI 830-240V Model (PolyJet/FDM/SLA/DLP/CLIP)

|

Safety Features |

Safety FeaturesEmergency stopAuto power down CE, UL/CSE certified |