Skip to content

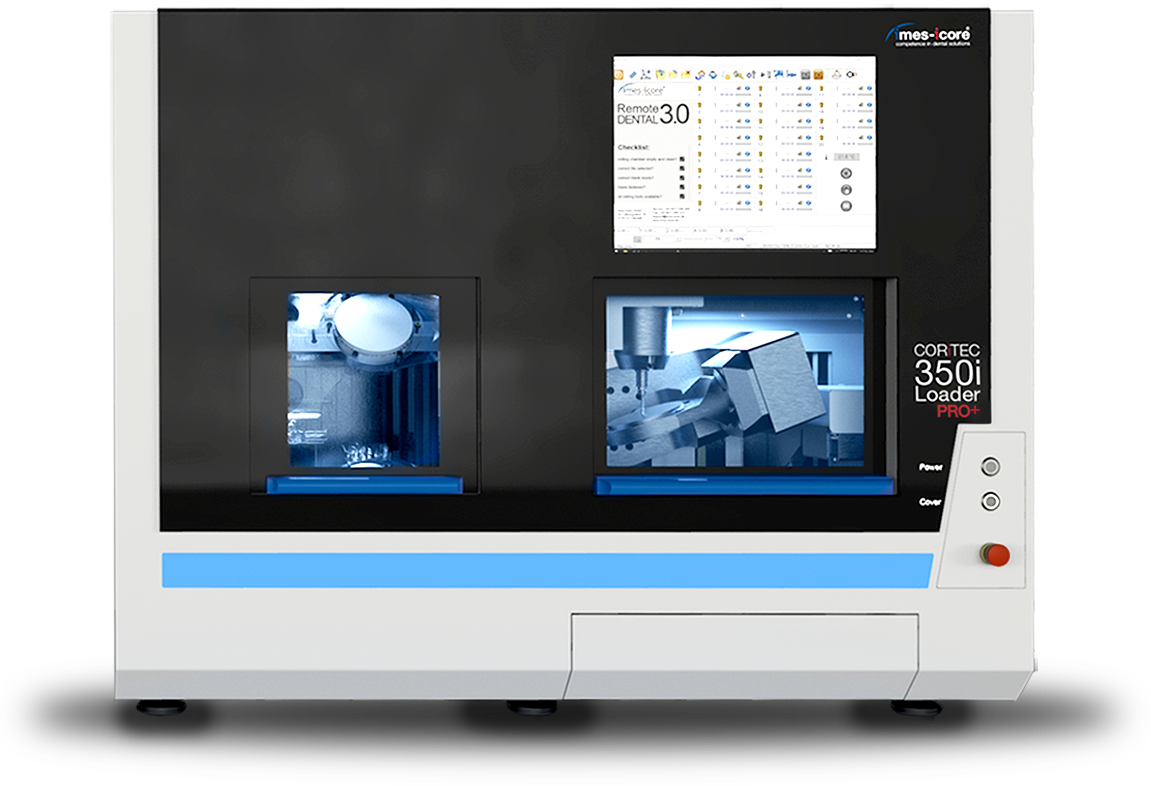

Dental Mills

Precise, reliable, and ready to work.

From the chairside to 24/7 automated production, our dental mills can complete your digital workflow

Dental Milling Solutions Designed for the Lab or Clinic

Our high-performance dental milling machines from imes-icore and VHF can transform your lab or clinic to meet the demands of today's digital ecosystems. With multi-axis capabilities, high precision, reliability, and the ability to tackle a wide range of applications and materials, our dental mills are perfect for any size lab including high volume production centers.