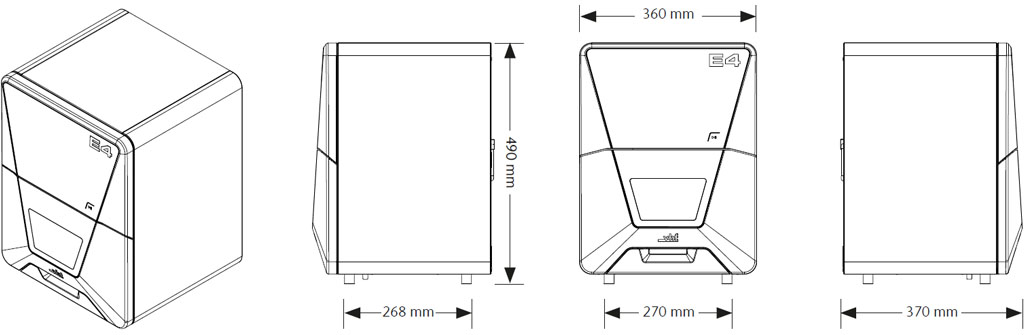

VHF E4

vhf®

E4 Dental Mill

Precision and ease of use in a compact design

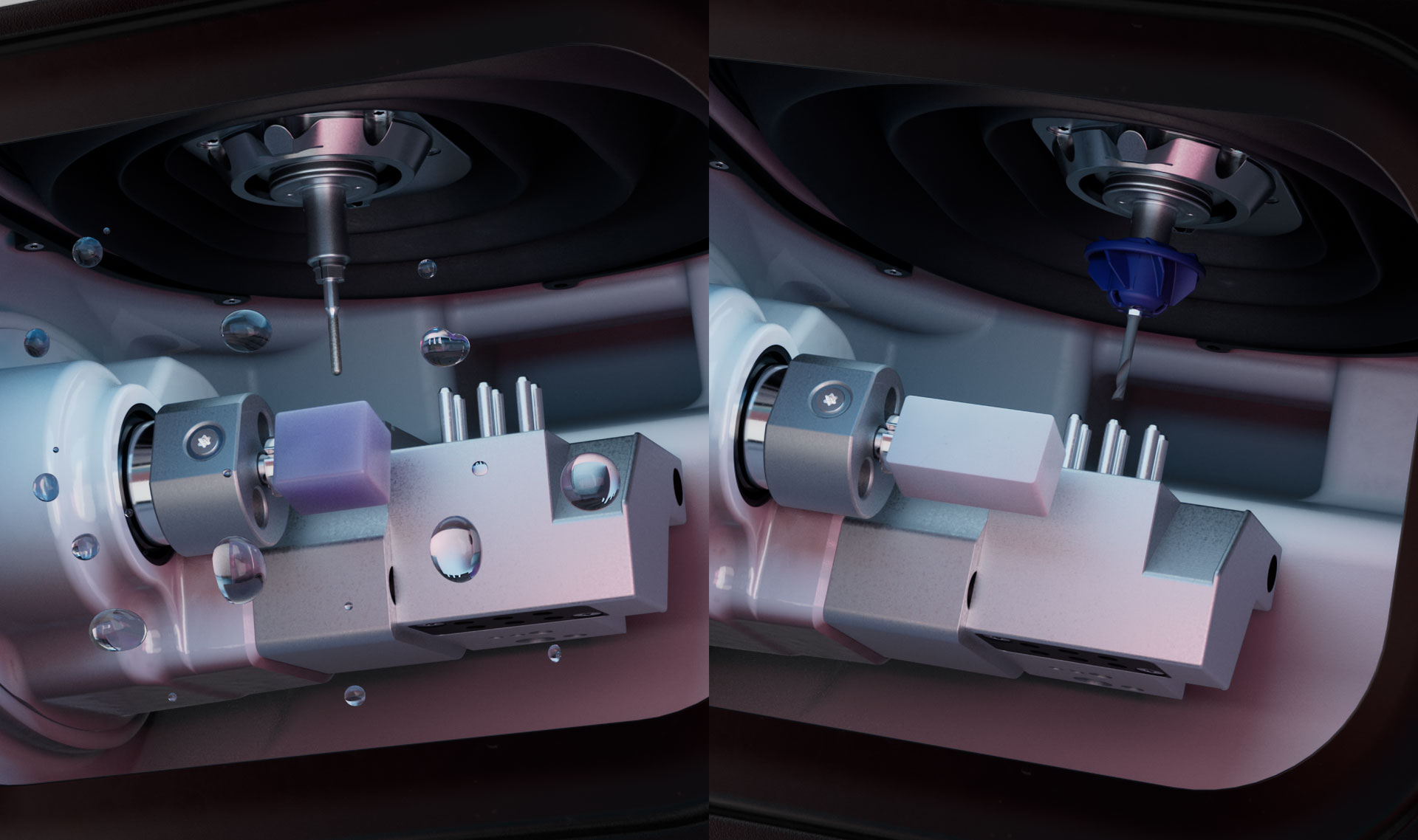

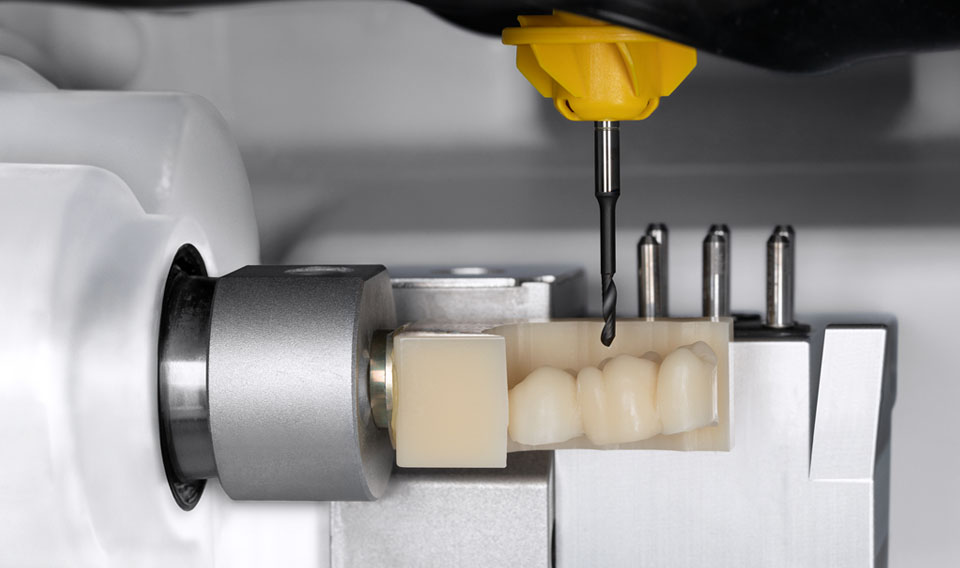

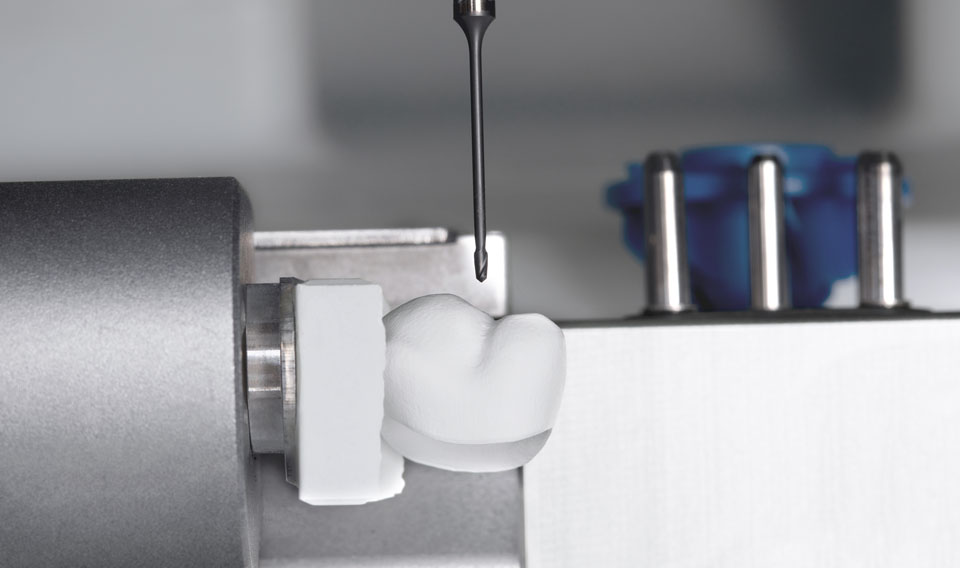

The vhf E4 is an innovative dental milling machine that simplifies same-day dentistry. With a weight of only 28 kg and no need for compressed air, it offers maximum flexibility in installation. The E4 is an all-rounder for blocks, allowing you to wet grind glass ceramics or composites and dry mill materials such as zirconia and PMMA. It also comes with integrated CAM software that enables you to get started right away. Experience the E4 and take your chairside workflow to the next level.

Features

Materials & Dental Indications

With vhf’s E4 dental mill, you can pick the materials of your choice. It grinds and mills a full range of materials for glass ceramics, composites, zirconia and PMMA – blocks up to 45 x 20 x 20 mm.

Technical Specifications

Construction |

ConstructionSturdy aluminum welded structure |

Housing |

Housing

|

Number of Axes |

Number of AxesFour (4) |

Linear Axes X-/Y-/Z-axis |

Linear Axes X-/Y-/Z-axis |

Rotary Axis |

Rotary AxisRotation angle: +190° to –10° |

Lighting |

LightingBacklit workspace through RGB LED lighting with status indication |

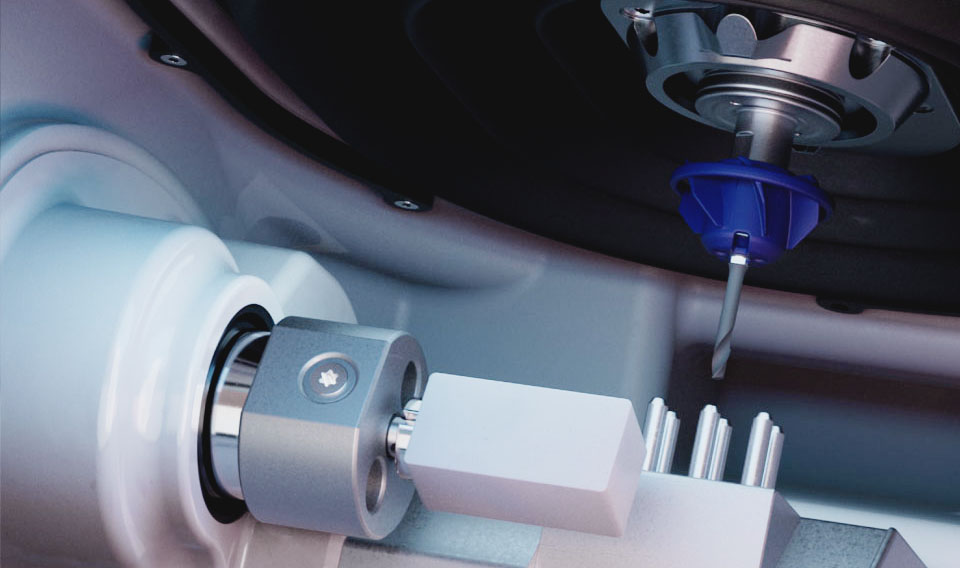

Spindle |

Spindle

|

Tool Change |

Tool Change

|

Access combination Compartment |

Access combination CompartmentDirect insertion of the coolant tank or (optional) dry container in the compartment directly under the working chamber |

Processing Modes |

Processing ModesWet

Dry

|

Connection Requirements |

Connection RequirementsPower supply: 100 - 240 volts; 50/60 Hz; 500 watts |