CORiTEC one and one+

imes-icore

CORiTEC one and one+

Advanced chairside milling for same-day dentistry

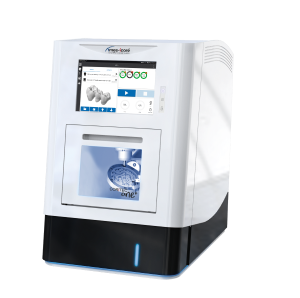

The new CORiTEC one® and one+ desktop dental milling machines from imes-icore enable intelligent and automated chairside digital dentistry. Designed as an open system for dental offices and practice labs, the CORiTEC one series can complete a digital workflow for a range of applications including pre-milled abutments, and single visit restorations. Discover the impact same-day dentistry can have for your practice by speaking with our experts.

CORiTEC one Key Features

- Mono-Block Cast Body – Novel closed mono-block cast body for stability and precision

- Ergonomic Handling – Simple Touchscreen Operation / Integrated PC

- Temperature Compensation – High precision due to integrated temperature compensation

- Powerful Performance – High end spindle for milling and grinding up to 100.000 rpm

- No External Compressed – Self-sufficient operation no external compressed air needed

- Multi-Adapter – Multi-adapter for up to three standard blocks or maxi blocks (65 x 40 x 20 mm)

- Wet milling possible

- Dry milling possible

- 4-axis machining

- 6 milling tools with 3 mm shaft diameter

- Temperature compensation

- Simple operation via touch screen

- Abutment

Highlights of the CORiTEC one & one+

Coritec one+

The extended chairside milling system

The CORiTEC one+ is the high-end model in the chairside area. Due to the 5-axis simultaneous technology, the C-Clamp holder and the blank holder can be integrated in addition to the single universal holder. This generates new application possibilities and more flexibility for creating the expected tooth restoration. The compact and stable basic design of the machine enables precise work in block and blank shapes.

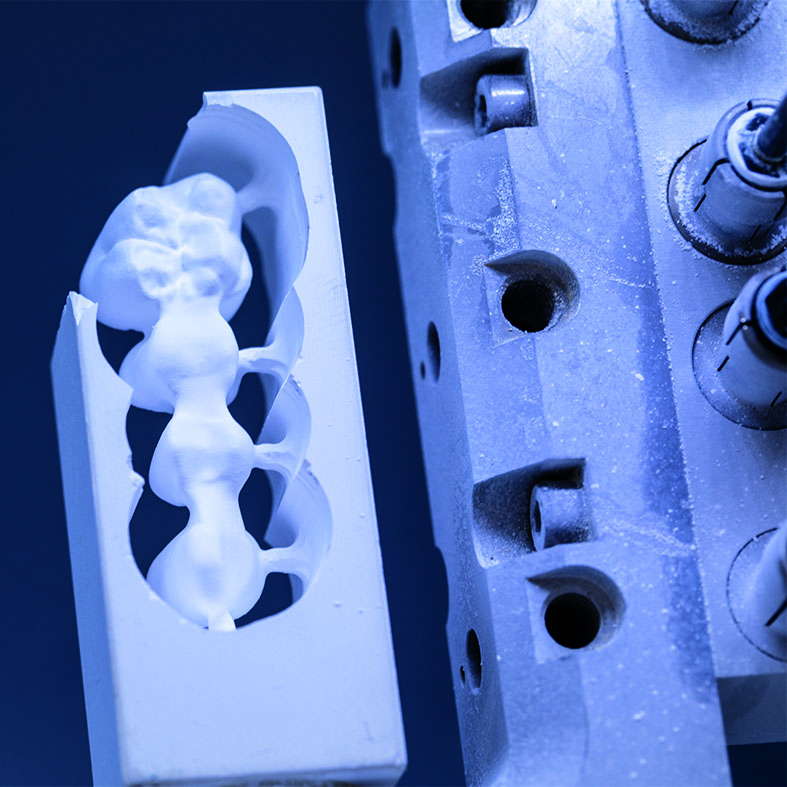

CAD/CAM block processing

The new CORiTEC one machine system is fitting perfectly for processing any common CAD/CAM blocks up to a size of 65 x 40 x 20 mm (maxi blocks). Thanks to the robust axis kinematics the machine is also able to process premilled abutments.

- Novel closed mono-block cast body for stability and precision

- Self-sufficient operation without external compressed air possible

- Optimized for the integrated CAD/CAM workflow with exocad/3shape

- Very fast grinding and milling process

- Short amortization period

- Minimal footprint

- High precision due to integrated temperature compensation

- Machining of all common material blocks and prefabricated abutments

- Multi-adapter for up to three standard blocks or maxi blocks (65 x 40 x 20 mm)

CORiTEC one – Maxi block zirconium dental grinding/milling

imes-icore® Chairside/Practice Lab

Workflow & Components

1. Data collection

To achieve a fully integrated workflow, the new Coritec one® machine system can be combined with various intraoral scanners such as Medit i500.

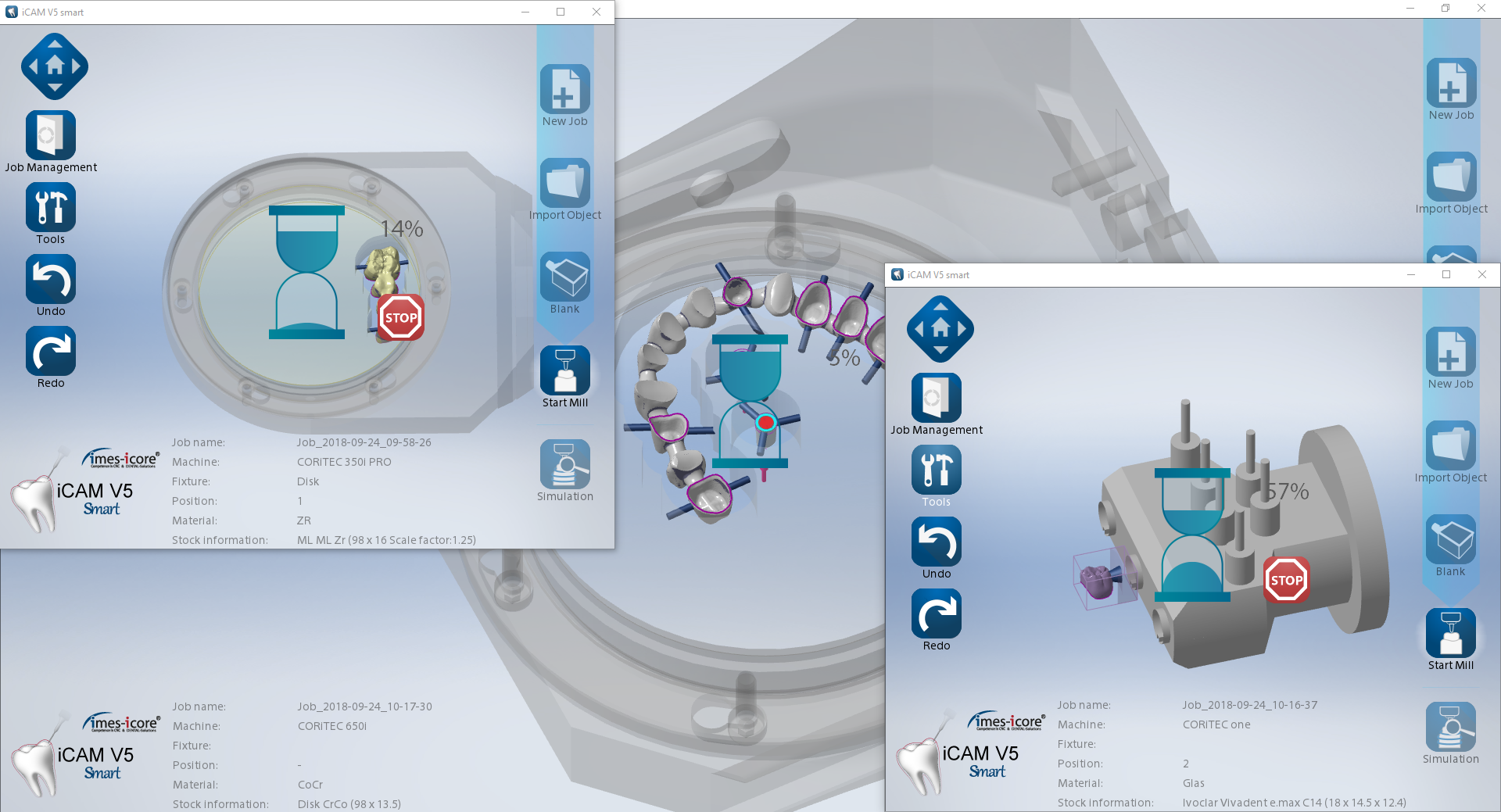

3. CAM software

- Coritec ICAM V5 Smart

- ICAM one+

- Any other CAM software on the market

4. Choose your materials

6. The end result

Applications Coritec one+

Available for Coritec One:

- 1-fold holder for blocks and pre-milled abutments

- Crown, bridge

- Inlay, onlay, veneer

- Abutment & Hybrid abutment

one vs. one+

Coritec One |

Coritec One+ |

|

Number of axes |

4 | 5 |

Number of tool positions |

6 | 10 |

Spindle power / rpm |

750 watt / 100.000 rpm | 750 watt / 100.000 rpm |

Quick-Clamping-System (manual) |

☑ | ☑ |

Dry processing |

☑* * optional |

☑* *optional |

Wet processing |

☑ | ☑ |

98 mm blank holder |

⚊ | included |

98 mm blank processing |

⚊ | ☑ |

CAD/CAM blocks/glass ceramics |

☑ | ☑ |

Premilled abutments |

☑ | ☑ |

Control-PC |

integrated | integrated |

10‘1“ HD touchscreen |

☑ | ☑ |

Integrated coolant tank |

integrated | integrated |

LED status bar |

☑ | ☑ |

Auto Calibration Set |

☑** ** in preparation |

☑** ** in preparation |

Compressed air |

no external air required | no external air required |

Collet |

3 mm stainless steel | 3 mm stainless steel |

C-Clamp processing |

⚊ | optional |

Integration in exocad® chairside workflow |

☑ | ☑ |

Universal fixture for glass ceramic and pre-milled abutments |

⚊ | ☑ |