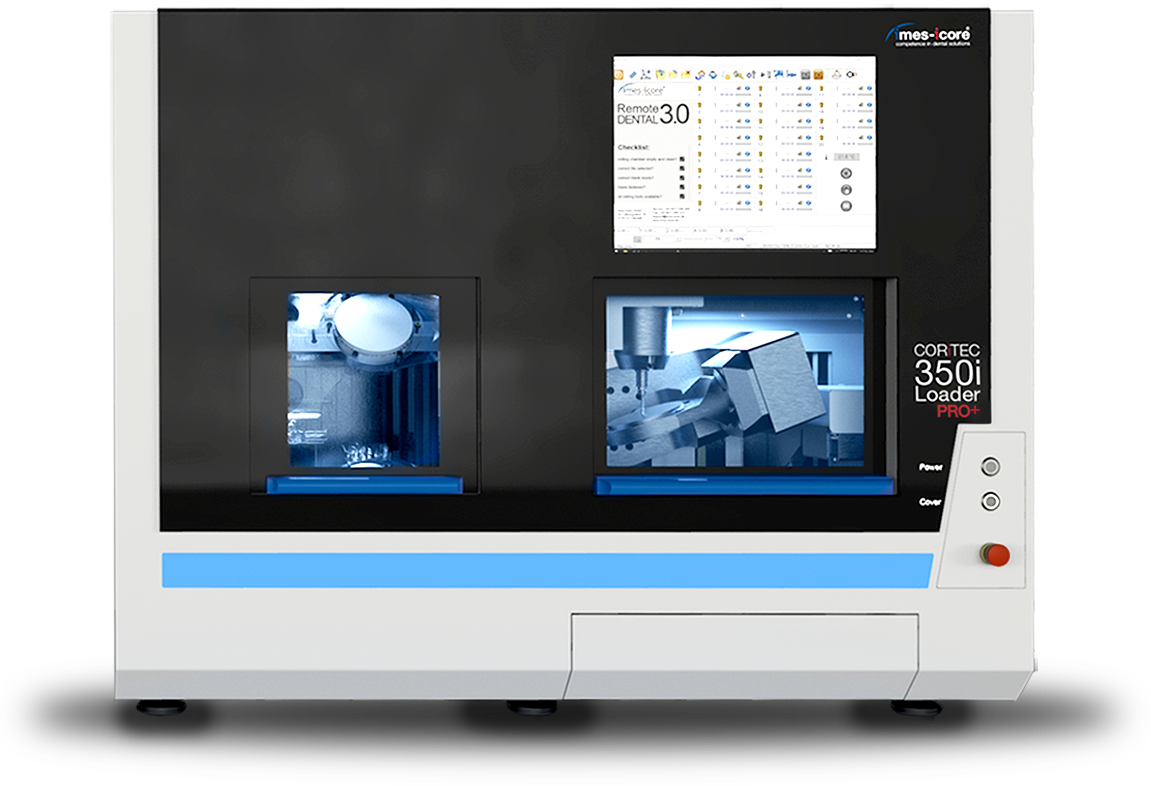

CORiTEC 350i PRO robot

Fully Automated in Perfection

The high-end system CORiTEC 350i PRO robot for milling centers has been realized on the latest generation of the CORiTEC 350i series. All installed components are designed for precision, longevity and the latest technological standards. Thanks to the robot, the production system enables independent milling and equipping with up to 84 dental blanks of various types. It is also possible to realize individual series production or production of different subsections. Thus, materials milling, grinding, polishing or laser can be processed. The system is individually adapted to customer requirements and tailored to your needs together with you. With the hyperFLOW management system, all projects are automatically monitored and managed from scanning through design to completion of the work.

CORiTEC 350i – Metal milling

CORiTEC 350i – Plastic milling

CORiTEC 350i PRO robot Key Features

- Fully Automated – Fully automated production line for all dental-relevant materials

- Ergonomic Automatic Polishing – Of milling aggregates

- Roboter Handling – For loading and unloading the machines

- Temperature Compensation – High precision due to integrated temperature compensation

- 24 Hours Production – Fully automated possible

- Job Management Software – For intelligent control

- Full Automation – With up to 84 blanks

- Expandable – On up to 5 x CORiTEC 350i PRO milling machines

- Final Processing – Optimal laser cutting and engraving system

- Wet milling possible

- Dry milling possible

- 5-axis milling

- 80 milling tools with 6 mm shaft diameter per machine

- Temperature compensation

- Simple operation via touch screen

- CAD/CAM Blocks

- Blank processing possible

- Blank stock up to 84 blanks

- ION optional possible

Applications

CORiTEC 350i PRO robot Specifications

Dimensions (W x D x H) in mm |

Dimensions (W x D x H) in mmDepending on the type |

Number of axes |

Number of axes5 |

Number of tool positions |

Number of tool positionsUp to 99 |

Pmax~ maximum spindle speed |

Pmax~ maximum spindle speed1 kW 60.000 rpm |

Drive motors |

Drive motorsAC-servo drives with absolute encoder |

Blank change / Number of blank holder |

Blank change / Number of blank holderAutomatic up to 21 blank holder per machine |

Dry processing |

Dry processingOnly for CoCr |

Wet processing |

Wet processingIdeally suitable |

Blank processing 98 / 98,5mm |

Blank processing 98 / 98,5mmIdeally suitable |

Block processing (CAD / CAM blocks) |

Block processing (CAD / CAM blocks)Ideally suitable |

Zirconium oxide / aluminium oxide |

Zirconium oxide / aluminium oxideIdeally suitable |

PMMA / Resins / PEEK / Composite / Wax |

PMMA / Resins / PEEK / Composite / WaxIdeally suitable |

Glass Ceramics / Hybrid Ceramics |

Glass Ceramics / Hybrid CeramicsIdeally suitable |

Sintered metal |

Sintered metalSuitable |

Chromium cobalt |

Chromium cobaltIdeally suitable |

Titanium |

TitaniumIdeally suitable |

Copings / Crowns / Inlay / Onlay |

Copings / Crowns / Inlay / OnlayIdeally suitable |

Bridges up to 3 items |

Bridges up to 3 itemsIdeally suitable |

Bridges up to 14 items |

Bridges up to 14 itemsIdeally suitable |

Telescopes |

TelescopesIdeally suitable |

Therapeutic splints (bite splints) |

Therapeutic splints (bite splints)Ideally suitable |

Tooth models |

Tooth modelsIdeally suitable |

Model cast |

Model castIdeally suitable |

Abutments on titanium adhesive basis |

Abutments on titanium adhesive basisIdeally suitable |

Prefabricated abutments of Ti /CoCr |

Prefabricated abutments of Ti /CoCrIdeally suitable |

One-piece abutments (Zr, resins) |

One-piece abutments (Zr, resins)Ideally suitable |

One-piece abutments (CoCr, titanium) |

One-piece abutments (CoCr, titanium)Ideally suitable |

Barr structures / one-piece abutment bridges on implants |

Barr structures / one-piece abutment bridges on implantsIdeally suitable |