FOLLOW-ME! hyperDENT®

FOLLOW-ME! hyperDENT®

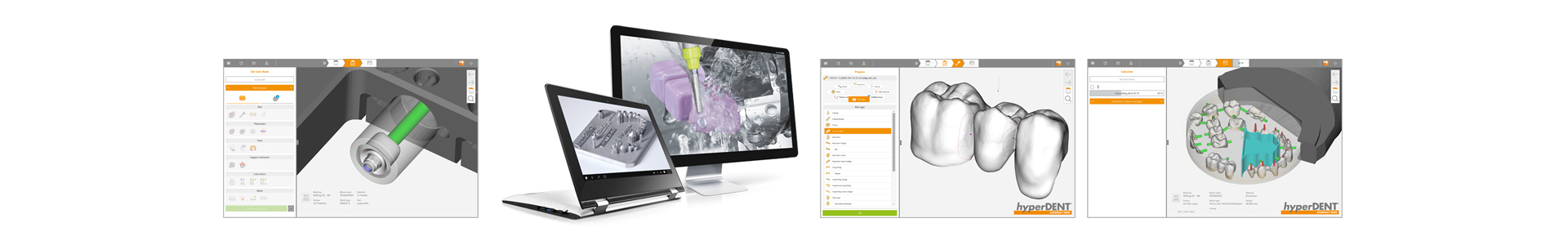

An open and automated CAD/CAM software system for dental milling

hyperDENT is a CAM software designed with solutions tailored to each lab's specific application and implementation needs. It is an open, fully automated system and it is available in three versions:

- hyperDENT Classic, for the advanced user

- hyperDENT Compact, used in dental labs and

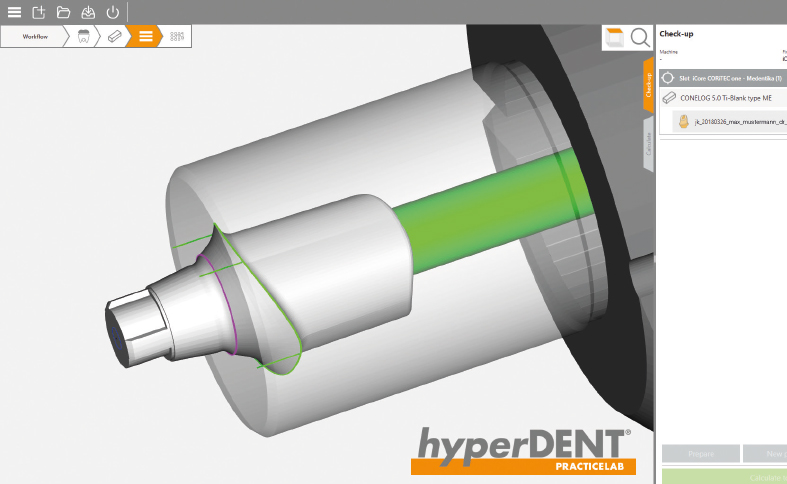

- hyperDENT Practicelab for practice labs and beginners in the CAM technology.

hyperDENT® is hyper-exciting

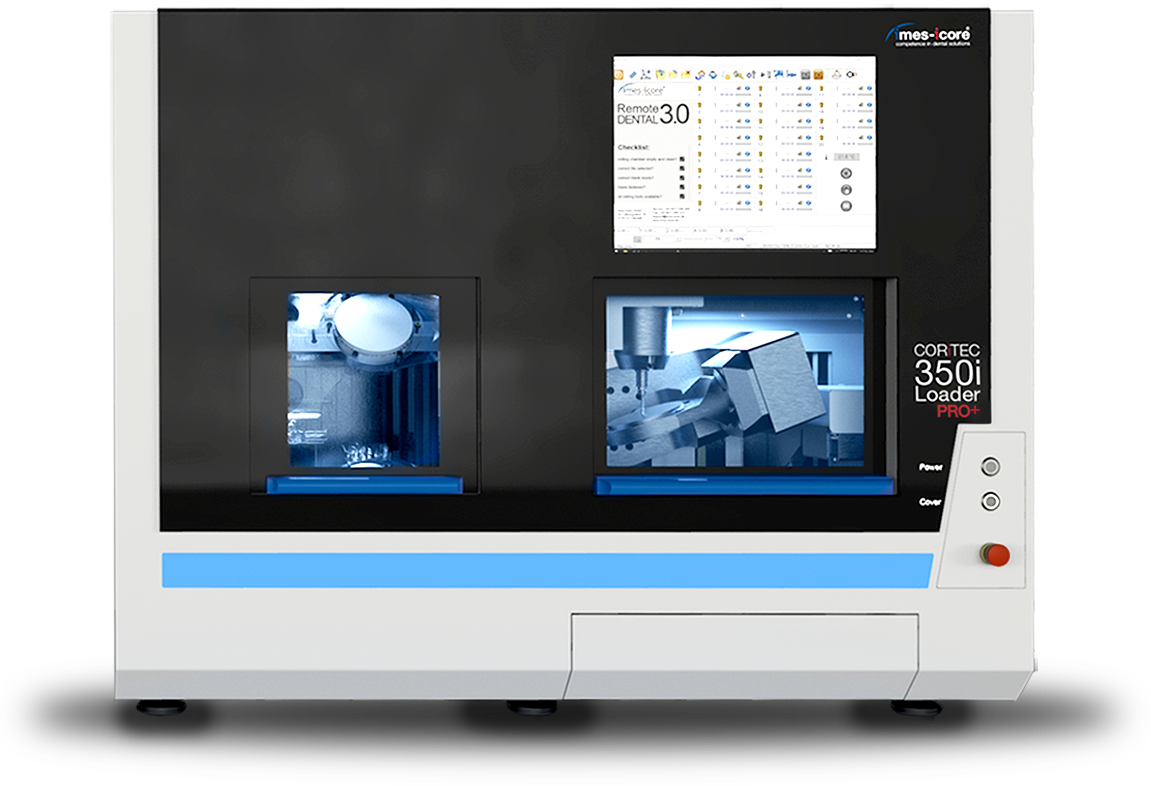

hyperDENT® is the world-leading CAD-CAM software system in the dental industry. It is well-recognized for its modular product structure. Whether you are a practice lab or a large dental lab, there’s a suitable hyperDENT® product bundle with exciting features for each of you. Moreover, it’s open software, therefore the type of your milling machine is no longer a concern. hyperDENT is compatible with a wide range of machines.

The advantages that get you the best milling strategies

|

|

Product & Function Overview

| Function | Function Description | hyperDENT® Practicelab | hyperDENT® Compact | hyperDENT® Classic |

| Template Generator Module | Writes and edits templates. Creates customized milling strategies, adapts tools and cuts data. | N/A | Optional | Optional |

| Template Generator Lite (TGL) | TGL modifies approved parameters. | N/A | Available | Available |

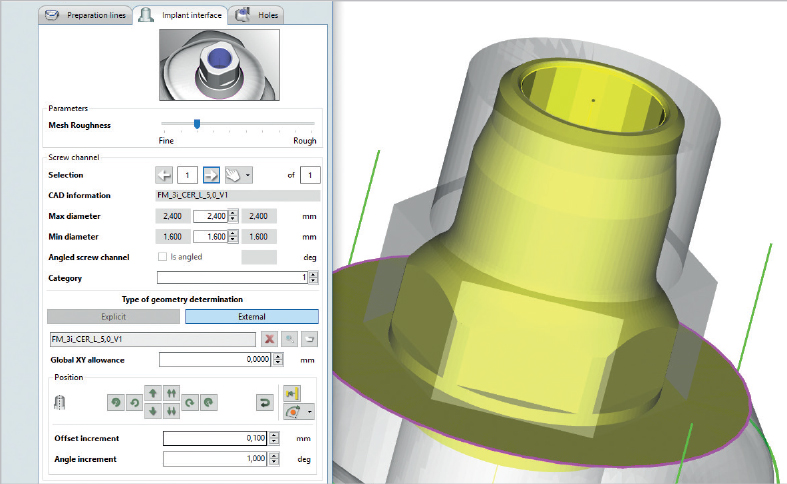

| Implant Module | It machines one-piece abutments out of the entire material. | N/A | Available | Available |

| Geometries | With this feature, you can prepare exchange geometries for fast and easy machining of abutments and multi-units. Implant module required. | N/A | Optional | Optional |

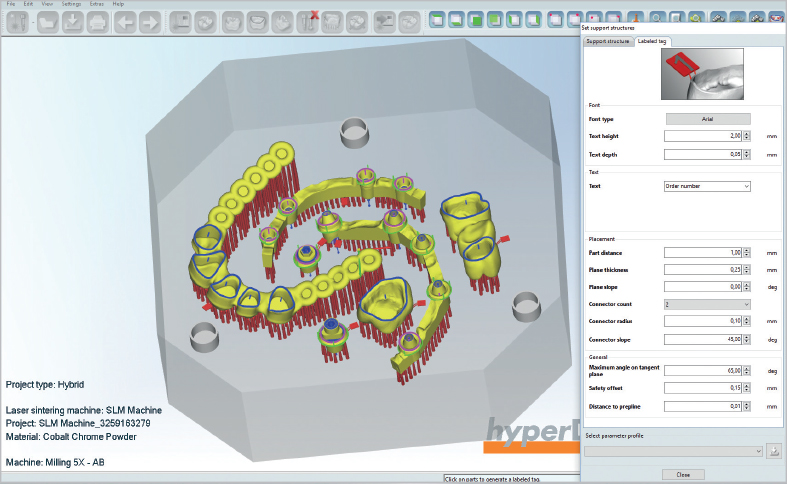

| Hybrid Module | The hybrid module controls laser sintering machines for hybrid manufacturing. | N/A | N/A | Optional |

| Full Denture Module | Thanks to this module, you can machine full dentures, including the Merz Baltic Denture System, with particular strategies. | Optional | Optional | Optional |

| Grinding Module | Machines glass-ceramic/lithium disilicate, etc., with unique, tool-protective cycles optimized for grinding. | Available | Optional | Optional |

| Multi-machine Usage | Operate any number of machines or machine types with a single hyperDENT® license. | N/A | Optional | Optional |

| Feature Detection | Detects preparation margins and screw channels without a CAD interface. | Optional | Available | Available |

| Multiple Instances | Starts hyperDENT® multiple times enabling work on multiple projects. | N/A | Optional | Available |

| Auto Part List | Connects hyperDENT® directly to output folder of CAD system. | Available | Available | Available |

| Load Wizard | Automatic initialization of workflow process steps. | N/A | Available | Available |

| User interface with “Click-Through” Workflow | User interface with simplified workflow for intuitive handling. | Available | Available | N/A |

| Project Management | Manages projects and blanks using lot and ID numbers. | Available | Available | Available |

| Project Report | Prints project reports and generates export files. | Available | Available | Available |

| Autonesting | Space-saving placement in the blank. Fixture-specific settings can be entered and various nesting parameters can be saved. | Available | Available | Available |

| User-Defined Areas | Defines user-specific areas for machining particular areas of the part. | N/A | Available | Available |

| Environment Filter | Automatically suggests the suitable blank. | Available | Available | Available |

| MachineConnect | Loads the milling program directly onto the machine and is activated in hyperDENT® (dependent on milling machine). | Available | Available | Available |

| Engraving | Engraves parts for identification. | N/A | Available | Available |

| Blank Milling | Mills all types of blanks and materials. | N/A | Available | Available |

| Block Milling | Mills blocks, such as glass-ceramic or hybrid ceramic blocks. | Available | Available | Available |

| Prefabs | Mills blanks with a prefabricated implant interface geometry. | Available | Optional | Available |

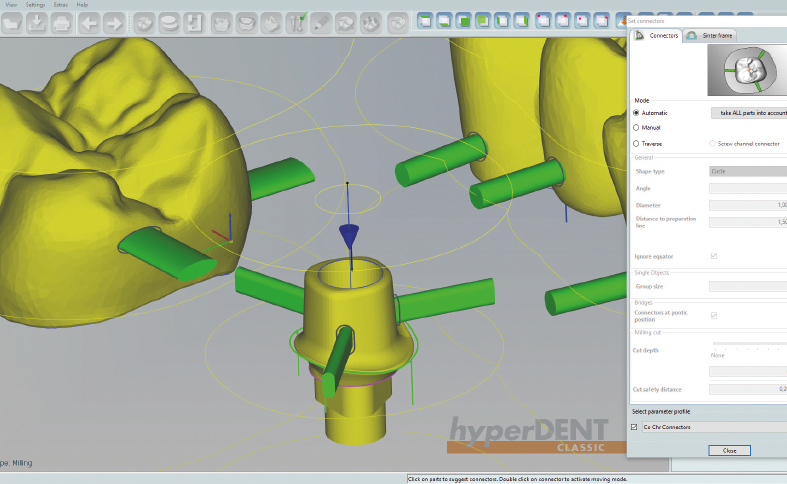

| Sinter Frames | Generates sinter frames for simple sintering of large bridges (i.e. zirconium oxide bridges). | N/A | Available | Available |

| Traverses | Saves space through spanning of traverses between multiple parts; occurs automatically for overlapping connectors. | N/A | Available | Available |

| Undercut Display | Displays undercut areas for the placement of user-defined areas. | N/A | Available | Available |

| Project Document | Displays details about the current project including screenshots. | Available | Available | Available |

hyperDENT® Modules

The following modules are available:

- hyperDENT® Template Generator Module

- hyperDENT® Hybrid Module

- hyperDENT® Implant Module

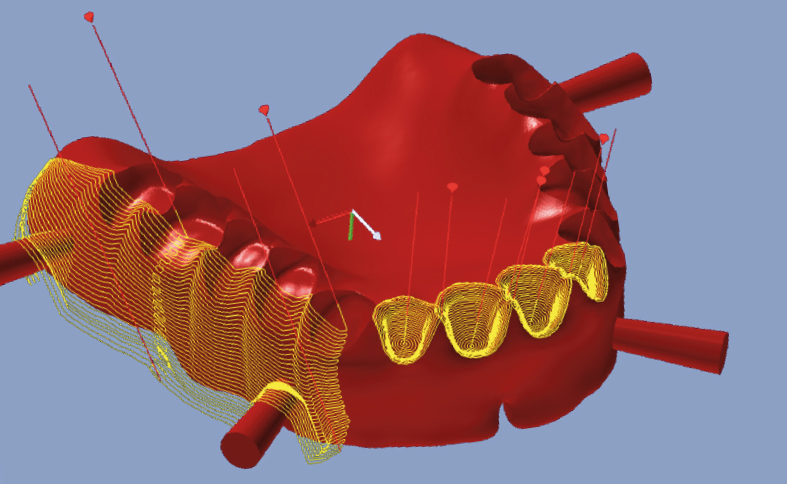

- hyperDENT® Denture Module

With hyperDENT® Options, you can add individual modules at any time to hyperDENT® Compact as well as hyperDENT® Classic licenses to perfectly match your requirements.

Features

Deep dive into the Features.

-

Auto part list

hyperDENT® can be directly connected to the output file of the CAD system

-

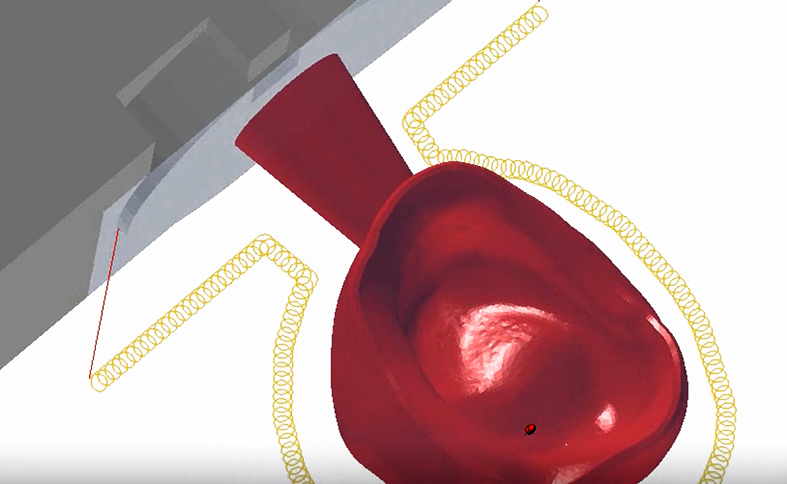

C-clamp function

hyperDENT® supports clamping devices which allow horizontal processing of dental parts

-

Undercut areas

Undercut areas can be automatically selected, which saves time in implementing

-

Insertion direction of cavities

The optimal insertion direction of cavities can be determined automatically.

-

Trochoidal milling

With “trochoidal milling”, significant time savings in manufacturing dental parts of different materials can be achieved.

-

Colour gradient simulation (multi-layer-disk)

The colour of multi-layer coloured blanks is transferred to the part so that they can be positioned in the blank according to the desired gradient.

-

Creation of customized templates

The hyperDENT® Template Generator Module enables you to create customized machining templates for all part types.

-

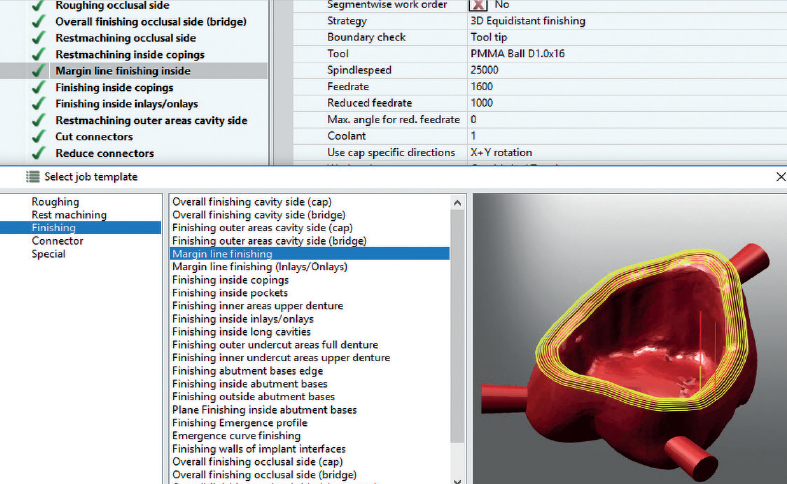

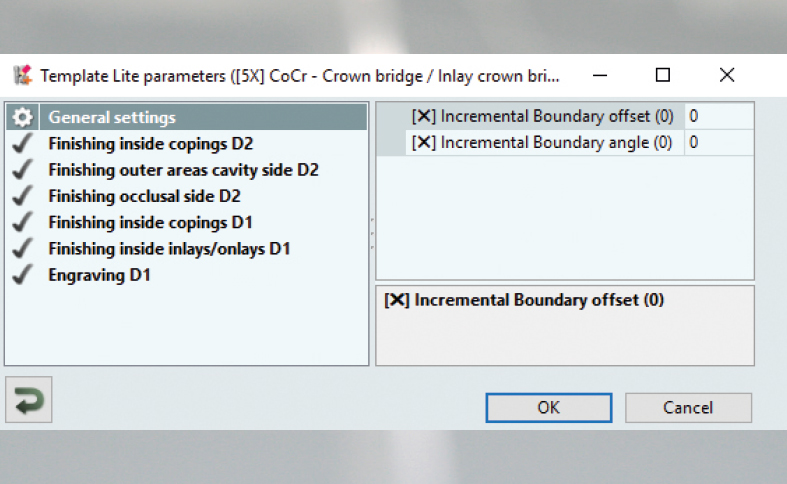

Template Generator Lite

hyperDENT® Template Generator Lite was integrated for modifications of basic parameters, such as tool path distance, allowance or milling area boundary.

-

Hybrid manufacturing of dental indications

The Hybrid Module enables the combination of additive and subtractive technologies in one workflow.

-

Milling of implants and geometries

With the Implant Module, customized abutments, implant bridges and bars can be manufactured from circular blanks.

-

Manufacturing of full dentures

The Denture Module enables digital manufacturing of full dentures with a significantly reduced processing time compared to the analog process.

-

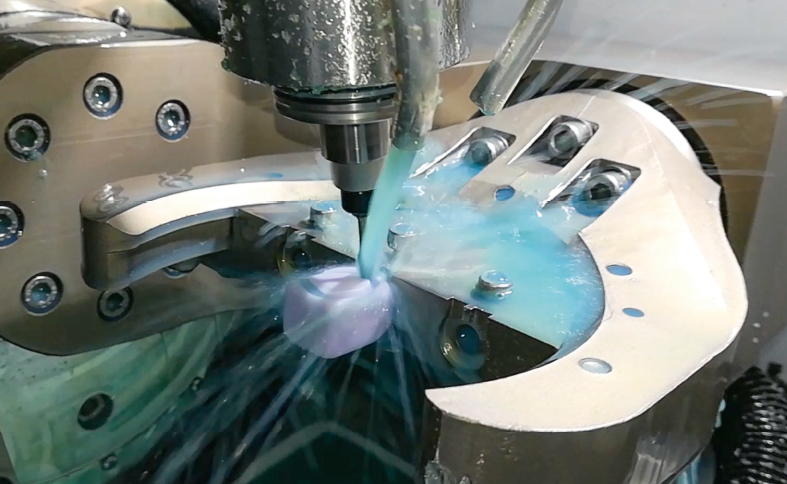

Glass-ceramic grinding

hyperDENT® enables simple and easy grinding of glass-ceramic using special strategies for the optimal generation of tool paths.

-

User Interface

The hyperDENT® Compact user interface design has been completely revised in line with user requirements.

-

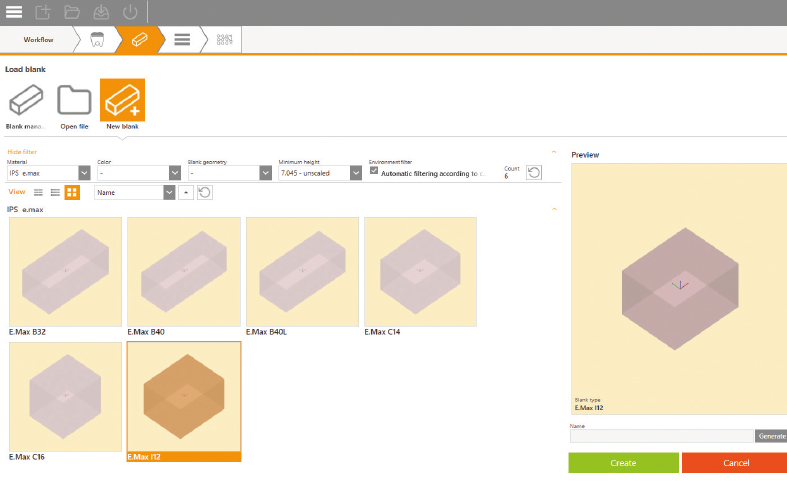

Intelligent blank suggestion

hyperDENT® automatically recognizes the blank required for processing and suggests this in a dialogue box including all known parameters.

-

Automatic placement of parts and setting of connectors

The optimal placement of parts to be machined occurs directly after blank selection.

-

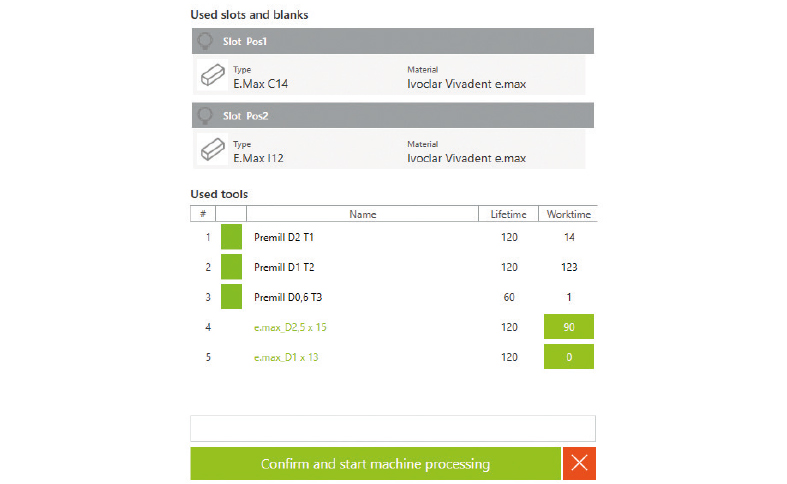

Customized milling data output and milling activation

The milling process can already be activated on the machine during the calculation of tool paths.

-

Prefab milling

It is also possible to mill prefab blanks without the hyperDENT® Implant Module.

-

User-defined areas

By establishing user-defined areas, a high degree of flexibility can be achieved using specific strategies and tools.

-

Connector profile and sintering frame

Using the connector and sintering frame profile, which can be set specifically for part types, special requirements can be managed for each indication.

-

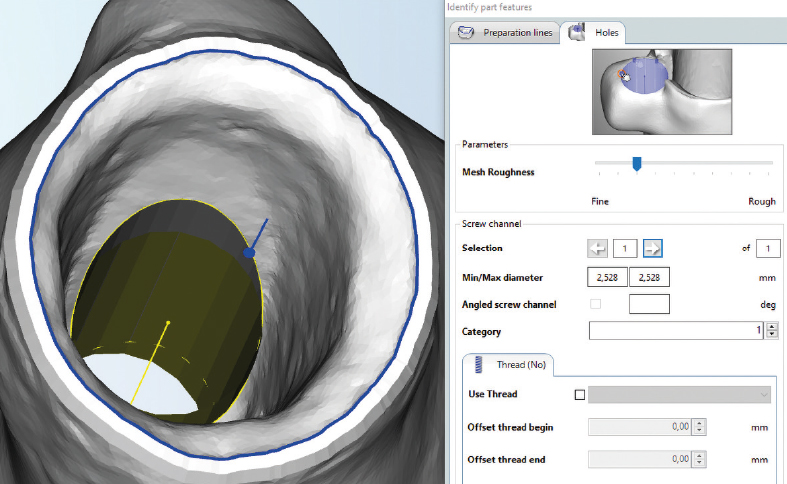

Cavity milling

The milling of cavities and holes is often required.

-

Environment filter

Using automatic recognition of the blank required for milling, all known parameters.

-

Engraving

Engraving objects after production simplifies the subsequent identification and allocation of parts.

-

Angled screw channels

With hyperDENT®, milling angled screw channels is not a problem.

-

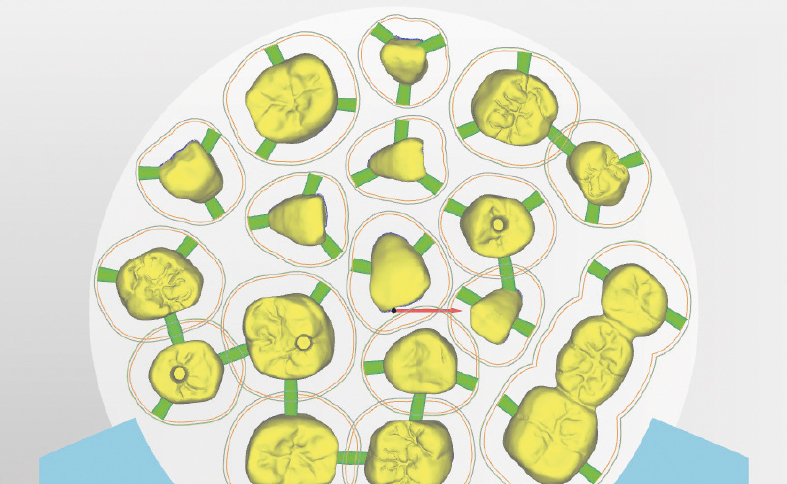

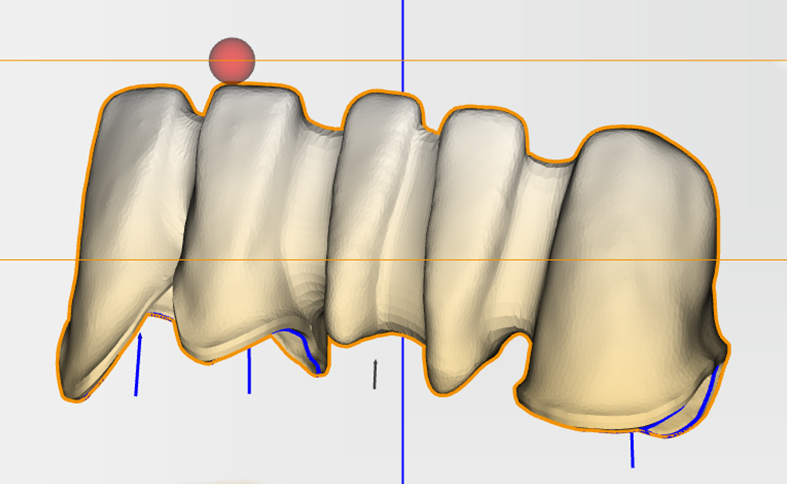

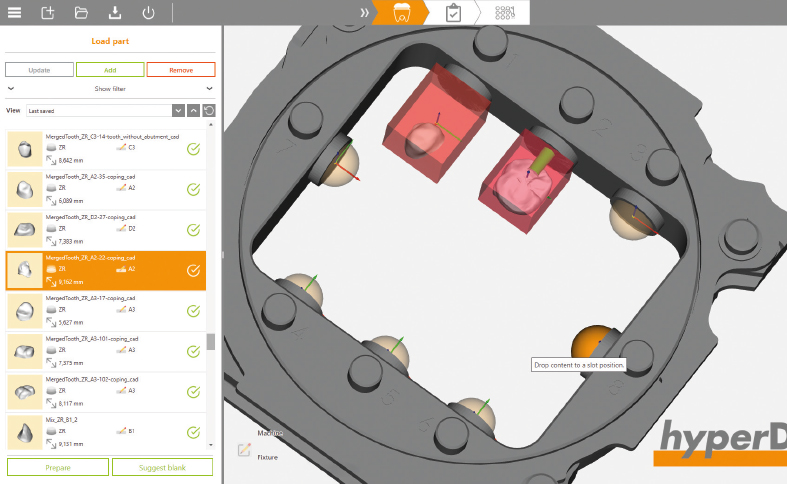

Auto nesting

During loading, hyperDENT® automatically places parts optimally in the blank.

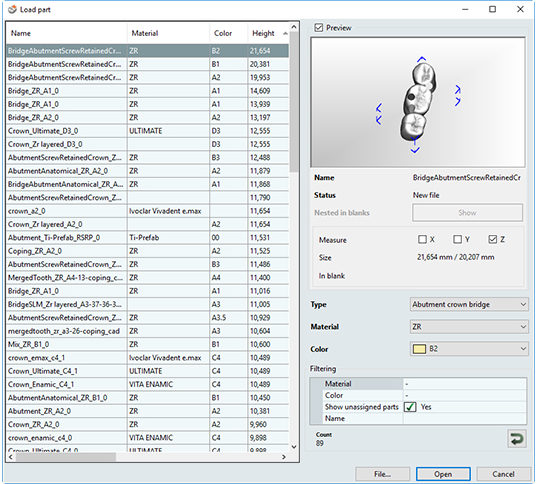

Auto part list

hyperDENT® can be directly connected to the CAD system’s output file, enabling the CAM to automatically recognize new designs and include them in the part list for further machining and management.

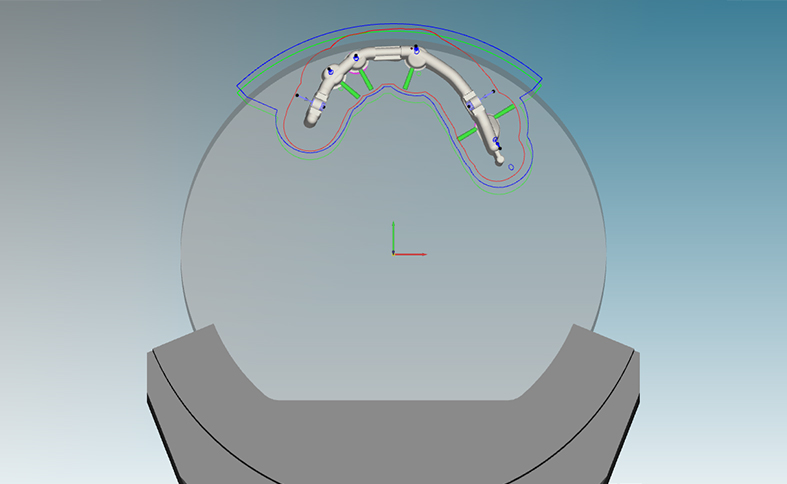

C-clamp function

hyperDENT® supports clamping devices which allow horizontal processing of dental parts (C-clamp). The utilization of lateral drilling and lateral details can now be fully automated.

|

|

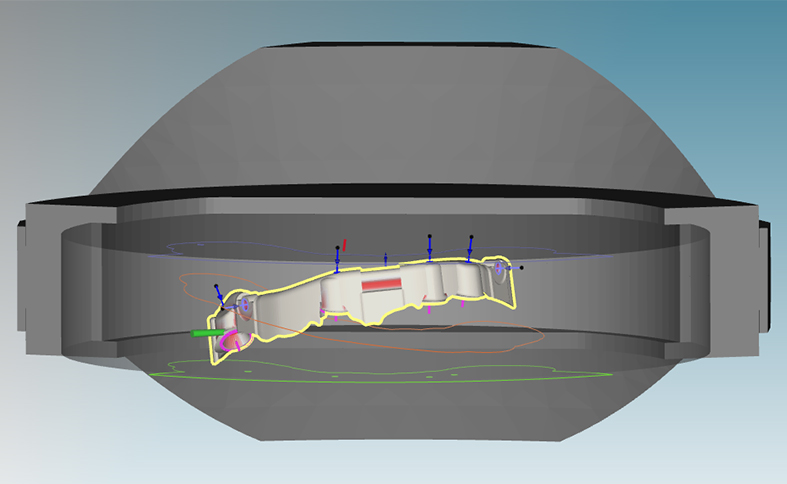

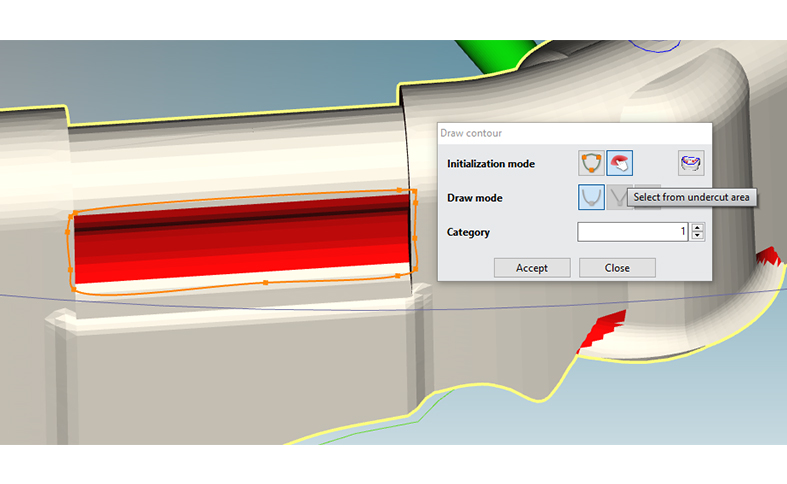

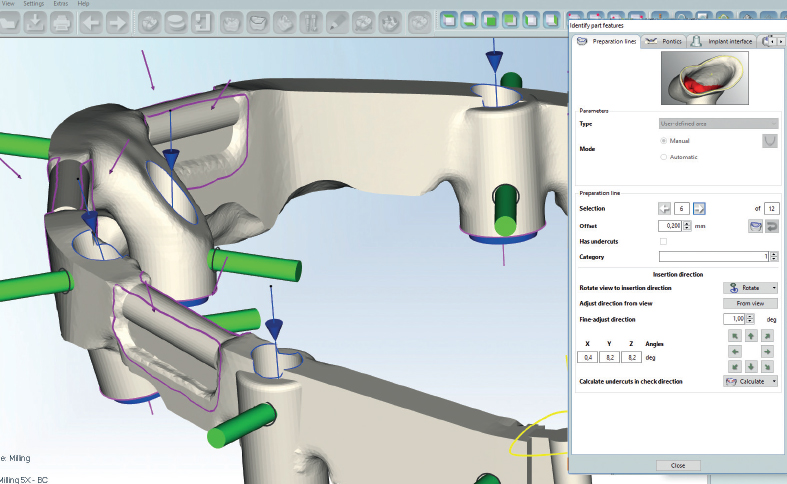

Undercut areas

Undercut areas can be automatically selected, which saves time in implementing non-accessible or difficult-to-access areas.

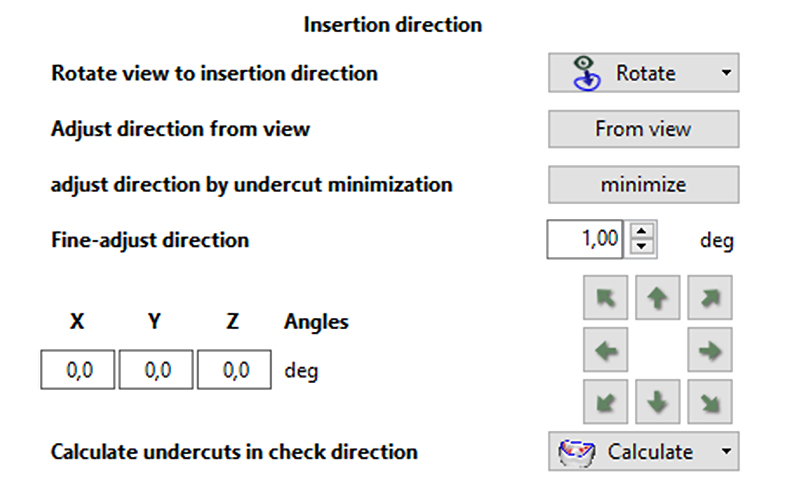

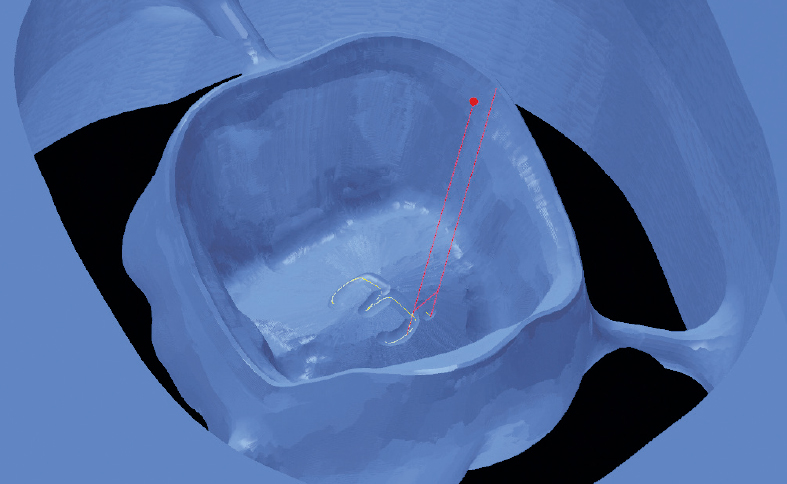

Insertion direction of cavities

The optimal insertion direction of cavities can be determined automatically. hyperDENT® always determines the best possible machining direction to avoid undercuts or to correct them.

Trochoidal milling

With “trochoidal milling”, significant time savings in manufacturing dental parts of different materials can be achieved. This is due to the controllable removal rate and the extensive possibilities for further machining in hyperDENT®.

Colour gradient simulation (multi-layer-disk)

The colour of multi-layer coloured blanks (multi-layer disc) is transferred to the part so that they can be positioned in the blank according to the desired colour gradient.

Creation of customized templates

The hyperDENT® Template Generator Module enables you to create customized machining templates for all part types, which can then be tested using material removal simulation. Thanks to the simple and intuitive user interface, an experienced CAM user can immediately begin creating and modifying machining templates (i.e. cutting data, tools, milling strategies).

Template Generator Lite

hyperDENT® Template Generator Lite was integrated to modify basic parameters, such as tool path distance, allowance or milling area boundary. This function enables users to make small adjustments independently without requiring the full version of the Template Generator Module.

Hybrid manufacturing of dental indications

The Hybrid Module combines additive and subtractive technologies in one workflow. Complex geometries, inner cavities and previously non-millable dental indications can be manufactured in high quantities with very high surface quality while using minimal material. Automated workflows, such as optimal nesting of the parts on the building platform, creating support structures or generating part-offsets in the areas to be post-milled, round off this all-in-one solution.

Milling of implants and geometries

With the Implant Module, customized abutments, implant bridges and bars can be manufactured from circular blanks. Due to intelligent categorization, only one master template is required for all systems. This module can also be combined with a millable interface geometry library for the most commonly-used implant systems. This library can be linked to a corresponding CAD dummy geometry library. It is easy to implement your own geometries as well. Despite possible inaccuracies in upstream systems, an automated exchange mechanism for geometries ensures that high-precision parts are manufactured.

Manufacturing of full dentures

The Denture Module enables digital manufacturing of full dentures with a significantly reduced processing time compared to the analog process. hyperDENT® is one of the first CAM software systems to provide specified and automated tool paths for this indication type. With the Denture Module, you can produce different workflow variations such as fully completed rows of teeth or pre-milled tooth pockets. Interfaces to diverse CAD systems are available and guarantee easy handling.

Glass-ceramic grinding

hyperDENT® enables simple and easy grinding of glass-ceramic using particular strategies for the optimal generation of tool paths. Where possible, the full tool circumference and length are used to extend tool life and guarantee high process stability.

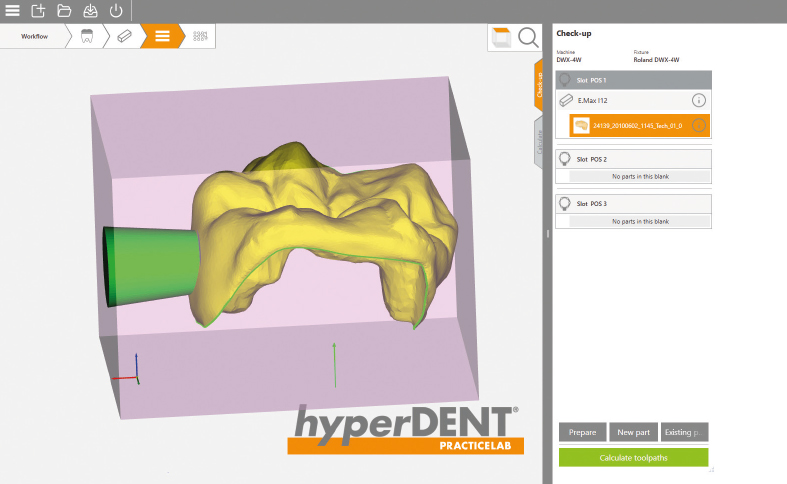

User Interface

The hyperDENT® Compact user interface design has been completely revised in line with user requirements. A higher degree of automation has been achieved due to the extremely simplified user interface and also due to the managed workflow. The calculation of a project can now be completed in just three steps with the workflow bar continuously displaying the current process step.

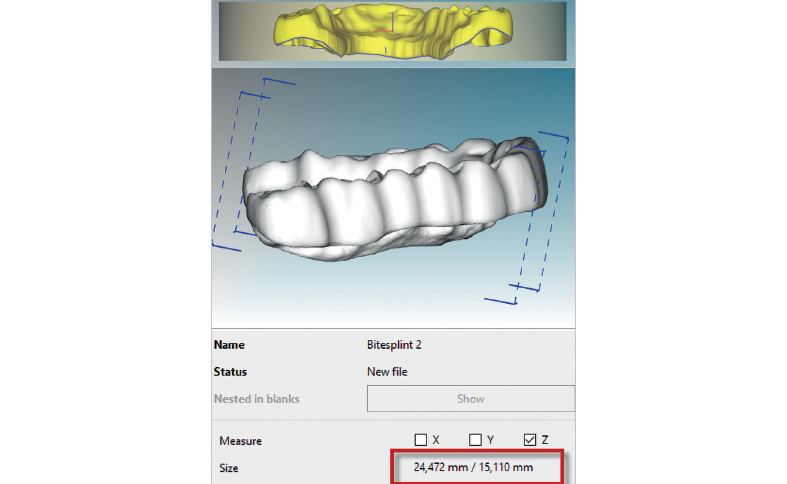

Intelligent blank suggestion

hyperDENT® automatically recognizes the blank required for processing and suggests this in a dialogue box, including all known parameters, such as material and part measurements.

Automatic placement of parts and setting of connectors

The optimal placement of parts to be machined occurs directly after blank selection. If rotating or tilting is required, this will be done automatically according to machine capability. Simultaneously, the connector (holding pin) will be set using the default parameters.

Customized milling data output and milling activation (MachineConnect)

The milling process can already be activated on the machine during the calculation of tool paths. Direct communication between hyperDENT® MachineConnect and the machine checks the current status and actions are taken accordingly. The scope of possibilities is dependent on the machine.

Prefab milling

It is also possible to mill prefab blanks without the hyperDENT® Implant Module (4 and 5-axis milling in a closed fixture or 4 and 5-axis simultaneous mill turning). By utilizing various milling strategies in different areas, optimum surface quality is guaranteed. The required blank is automatically selected through the database’s configuration, saving time and preventing errors.

User-defined areas

By establishing user-defined areas, specific strategies and tools can achieve a high degree of flexibility. Categorizing user-defined areas enables many application possibilities (i.e. attachment, customized milling of residual material), even using the same milling part (available in hyperDENT® Classic).

Connector profile and sintering frame

Special requirements can be managed for each indication using the connector and sintering frame profile, which can be explicitly set for part types. Form and position can be edited individually. The algorithm for optimized nesting of the connector position guarantees a quick and easy workflow for the tool path calculation, even for overlapping milling areas.

Cavity milling

The milling of cavities and holes is often required. hyperDENT® is capable of milling these with all part types. Through categorization, different requirements can be managed easily, even for the same part.

Environment filter

Using automatic recognition of the blank required for milling, all known parameters (i.e. material, machine, part measurements) are considered for the selection. Only blanks that fit will be included in the dialogue, which simplifies the blank selection.

Engraving

Engraving objects after production simplifies the subsequent identification and allocation of parts. The engraving can be placed individually for parts using the workflow bar symbol or automatically using parameters. Material-dependent profiles can also be created.

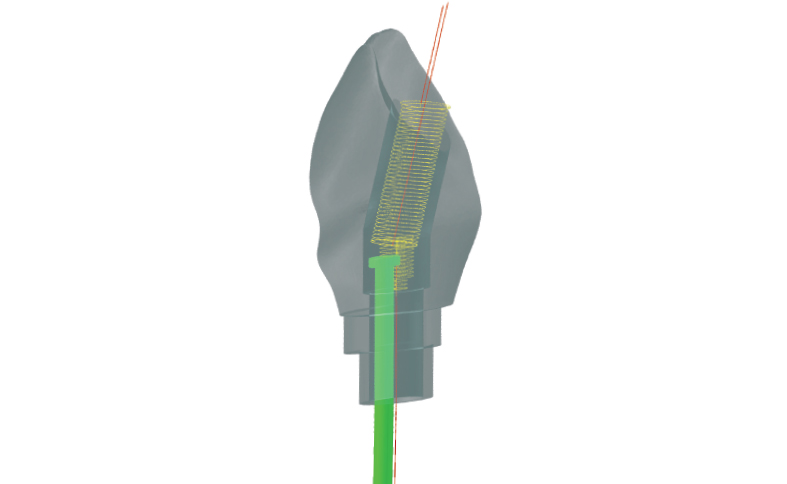

Angled screw channels

With hyperDENT®, milling angled screw channels is not a problem. It is just as easy as milling normal screw channels due to manual or automatic recognition. Optimized milling jobs using slot milling cutters ensure an easy milling process.

Auto nesting

During loading, hyperDENT® automatically places parts optimally in the blank. Additional local nesting assists in finding the ideal position within the radius during manual nesting.