VHF K5+

vhf®

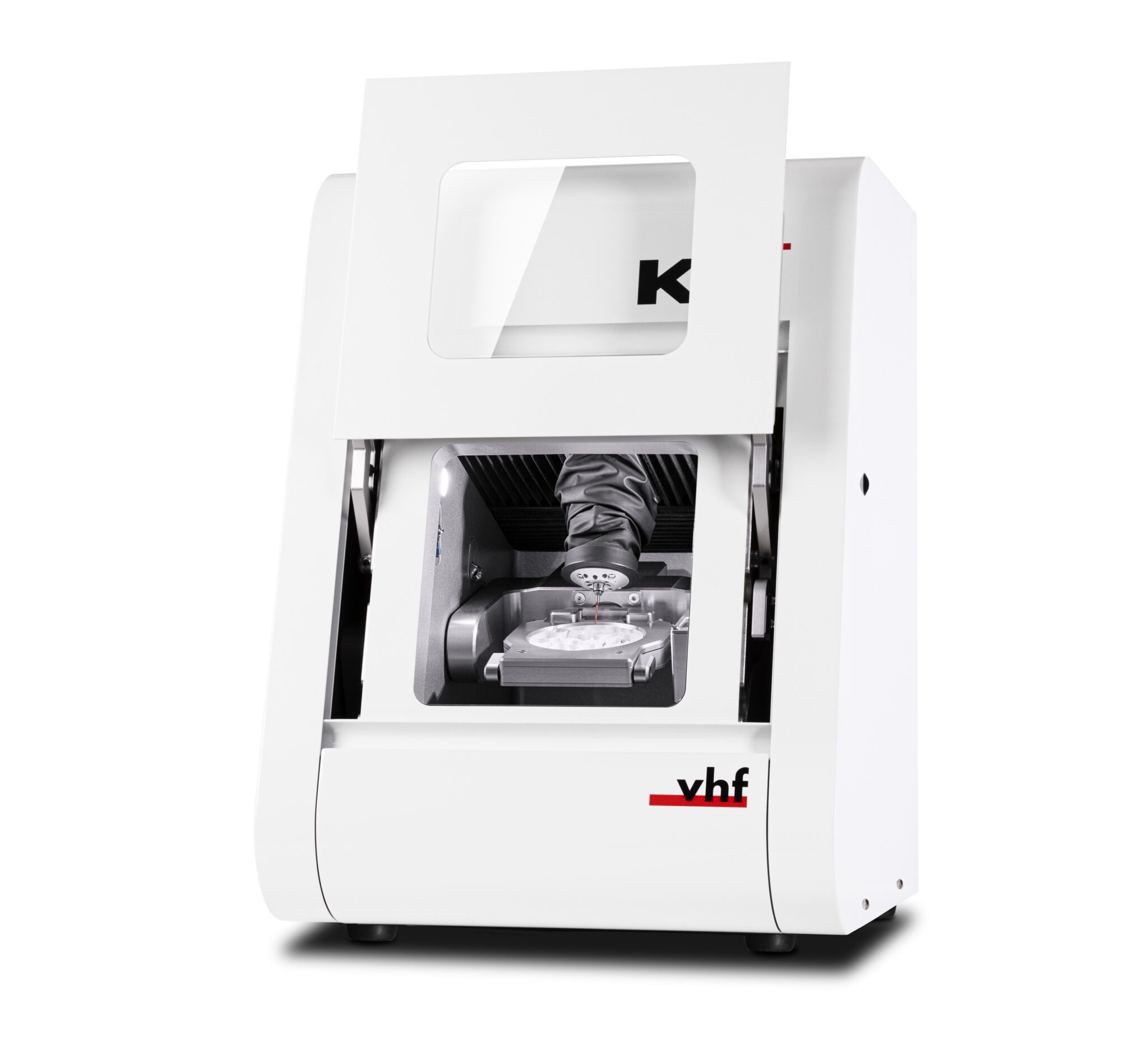

K5+ Dental Mill

Extra Spindle Power for High Performance in Any Dental Laboratory

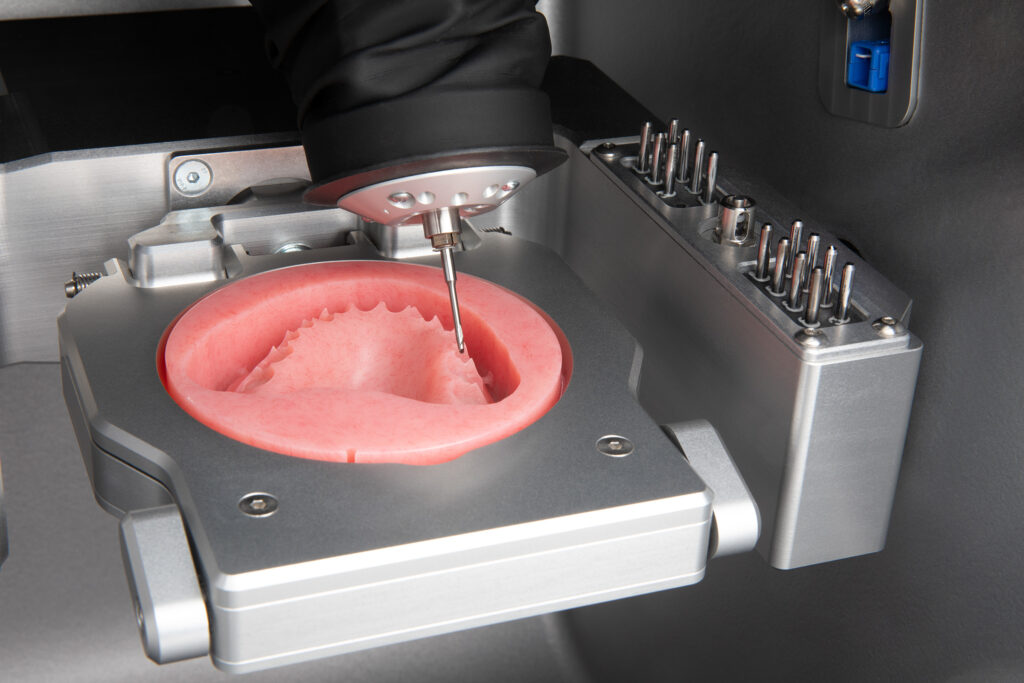

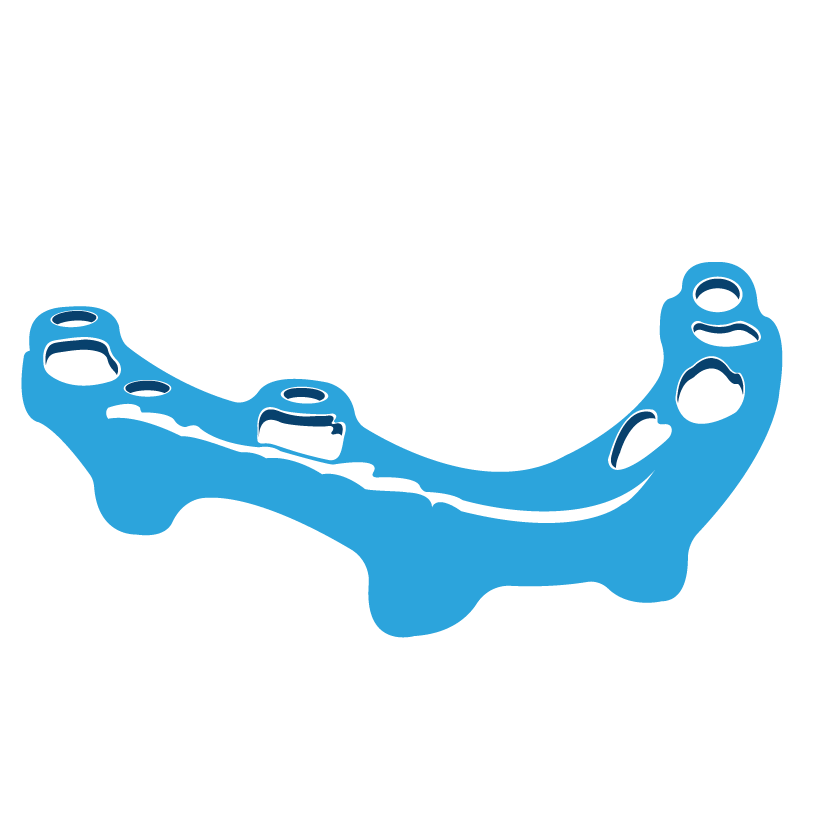

vhf®'s K5+ system is a five-axis dental milling machine extra spindle power that can easily mill tough materials such as cobalt-chrome. It is particularly efficient in dry milling with proven reliability in any dental laboratory.

Exceptional for Hard Materials

The K5+ from vhf® has a fresh new design and an upgraded spindle, which is over 60% more powerful. This enables the machine to work with tough materials like cobalt-chrome with ease. The K5+ is known for its reliability and continues to deliver precision and efficiency in any laboratory setting.

Features

Highlights

Dental Applications

What Materials Can You Process with K5+?

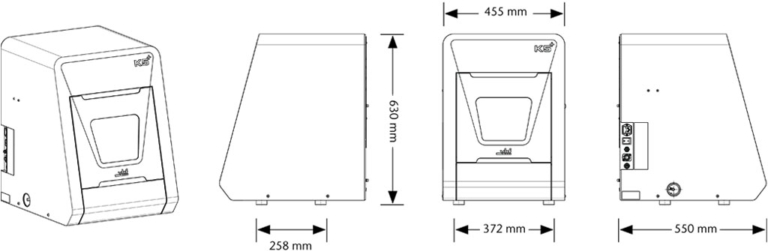

Technical Specifications

Field of Applications |

Field of ApplicationsDry Machining |

Materials |

Materials

|

Base System Construction |

Base System ConstructionMachine bed made of solid cast aluminum body |

Base System Housing |

Base System HousingSheet steel housing, white high-gloss lacquer finish with working chamber flap and accessories drawer |

Axes |

Axes

|

Control Unit |

Control Unit5-axis simultaneous control electronics with continuous path progression and dynamic pre-calculation · hardware-based real-time operating system with standardized instruction set · FPGA-integrated processor · updateable hardware · real-time path calculation via dedicated hardware engines in the FPGA · four-quadrant control of the motors for particularly smooth running · multiple analogue and digital I/Os for controlling the peripherals · integrated inverter for synchronous and asynchronous motors, electronic gate detection · Ethernet and USB interface |

Lighting | Camera | ATB |

Lighting | Camera | ATB

|

Spindle |

Spindle

|

Collet |

ColletStainless steel collet for tools with 3 mm shank diameter and max. 40 mm total length |

Automation |

AutomationTool magazine for 16 tools · Length measurement and tool breakage monitoring via precision measuring key · Access via working chamber flap, safety-locked |