Formlabs® Form Wash & Wash L

Formlabs®

Form Wash & Wash L

Automated Post-Processing for Peak Performance

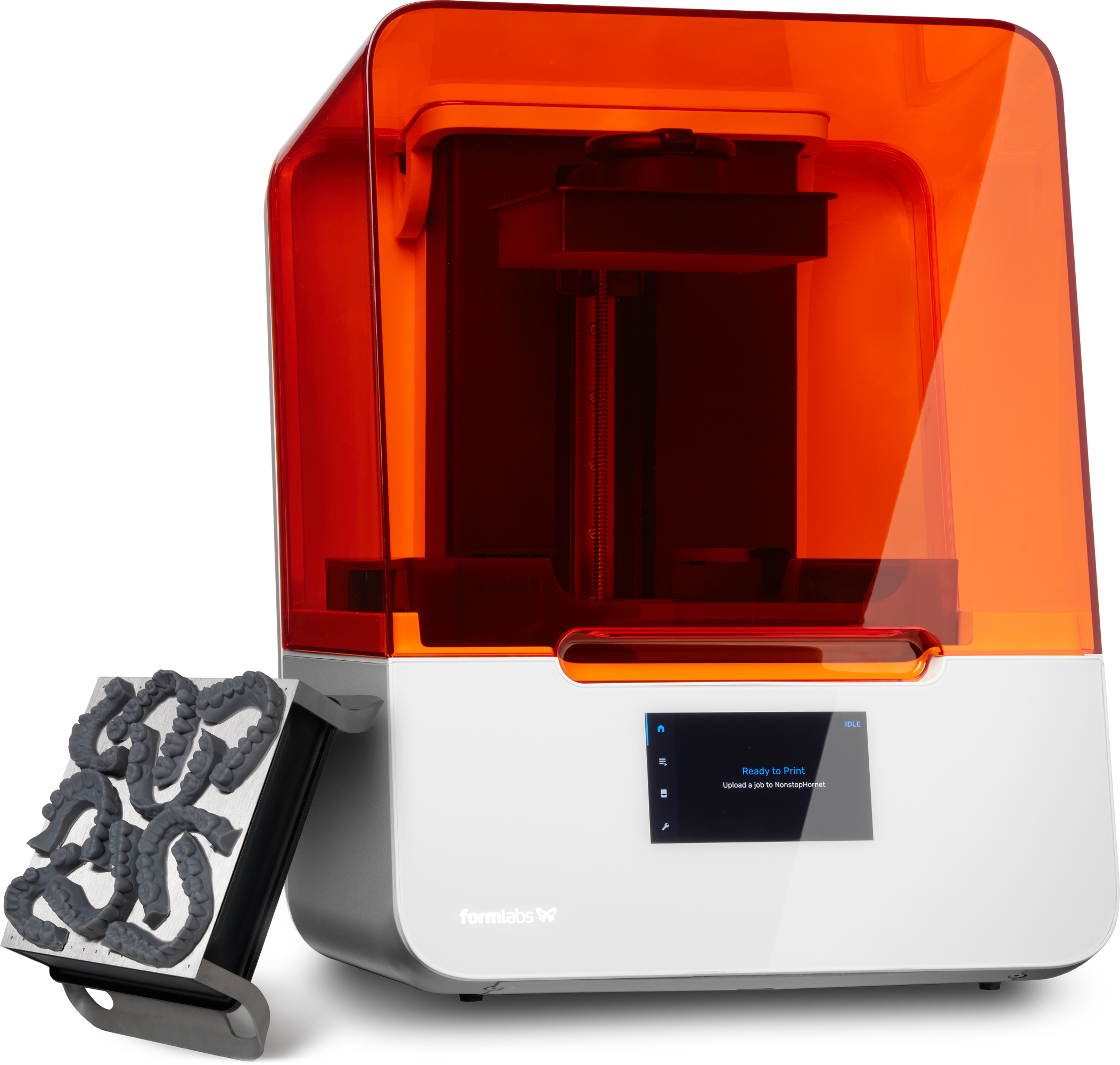

After printing, parts that are produced using stereolithography need to go through a post-processing treatment to obtain the desired durability and a smooth surface finish. Formlabs® solutions, Form Wash and Form Cure, have been tried and tested in a start-to-finish dental 3D printing workflow that is certified biocompatible. You can equip your dental office or lab with automated and simple post-processing systems for larger production volumes such as the Form Wash L and Form Cure L models.

Form Wash & Form Wash L

Technical Specs

Form Wash |

Form Wash L |

|

Printer Compatibility |

Form 3+, Form 3B+, Form 3, Form 3B, Form 2 | Form 3L, Form 3BL, Form 3+, Form 3B+, Form 3, Form 3B, Form 2 |

Dimensions |

26.2 x 29.3 x 34.0 cm 10.3 x 11.5 x 13.4 in Height when open: 64 cm (25.2 in) |

78.0 x 46.0 x 67.0 cm 30.7 x 18.1 x 26.4 in Height when open: 113 cm (44.5 in) |

Weight |

6.7 kg / 14.5 lbs |

56.7 kg (without solvent) 125lbs (without solvent) |

Bucket Volume |

8.6 L |

37.9 L 10 US gal |

Maximum Part Size |

14.5 × 14.5 × 17.5 cm 5.7 x 5.7 x 6.9 in |

33.5 x 20 x 30 cm 13.2 x 7.9 x 11.8 in |

Suggested Operating Environment |

Suggested 18 - 28 °C Suggested 64 - 82 °F |

Suggested 18 - 28 °C Suggested 64 - 82 °F |

Agitation Method |

Magnetically coupled impeller | Magnetically coupled impeller |

Power Requirements |

90–240 V 2.0 A 50/60 Hz 50 W |

100–120 V (NA), 220 - 240 V (EU) 1.0 A 50/60 Hz (NA), 1.0 A 50/60 Hz (EU) |

Compatible Solvents |

IPA, TPM, Water | IPA, TPM, Water |

Included Accessories |

|

|