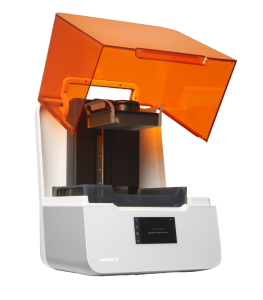

Formlabs® Form 3B+

Formlabs

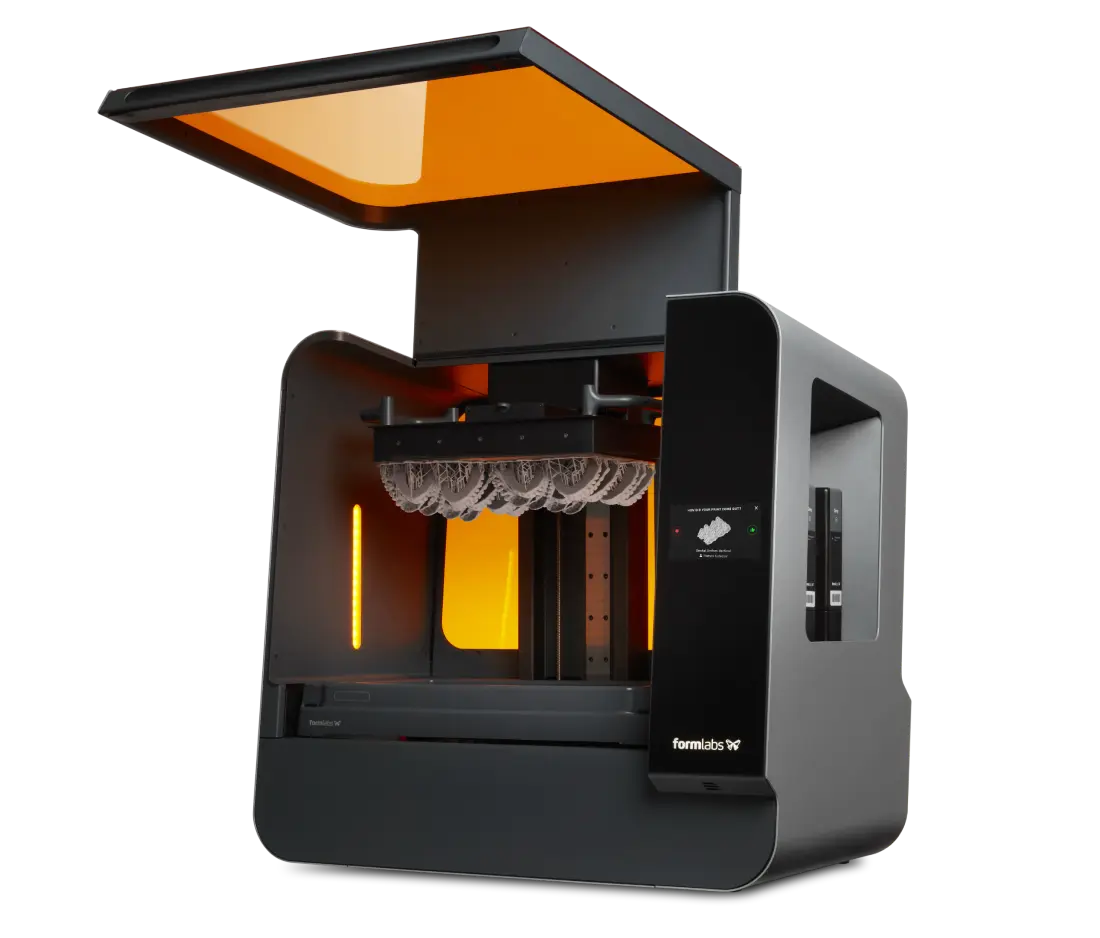

Form 3B+

Simple 3D printing workflows designed for dentistry

The Formlabs Form 3B+ provides dental professionals with an easy-to-use desktop 3D printing solution for a wide variety of applications. Utilizing innovative hardware and software, the Form 3B+ delivers fast print speeds while maintaining the consistent, high-quality printing that Formlabs is known for. Optimized for functional, biocompatible, and sterilizable materials, this 3D printer allows for same-day printing of patient specific parts at the point of care.

Bring 3D Printing Chairside with the Formlabs Form 3B+

Designed for the clinic or lab and powered by Low Force Stereolithography™ technology, Form 3B+ delivers extraordinary surface finish and print accuracy across multiple dental applications. With its ability to produce high-quality parts without any difficulties or excessive expenses, it is the ideal solution for digital dentistry, whether you are prepared to scale up or you’re adopting additive manufacturing for the first time.

Features

Explore the Form 3B+ 3D Printing Ecosystem

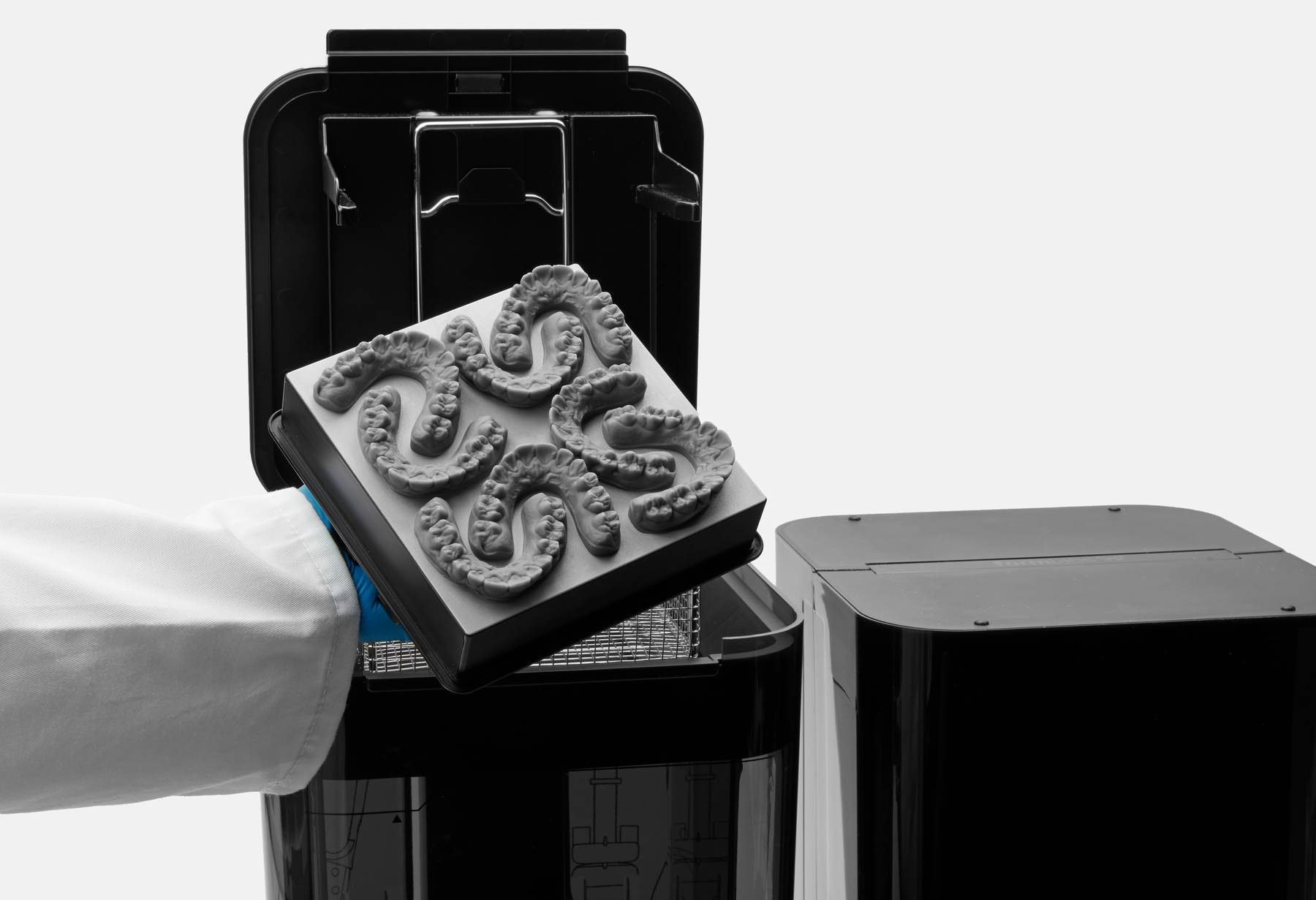

Seamless experience with validated workflows

for dental clinics & labs

Form 3B+ is an all-encompassing digital workflow solution, including intuitive and innovative software, a resin portfolio for 10+ indications, including various biocompatible materials, and simple, automated post-processing.

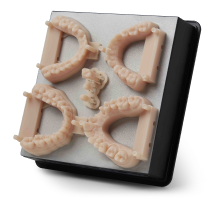

Draft Dental

Material: Formlabs® Draft Resin

Draft Resin is a cutting-edge material that prints orthodontic models. You can print a single arch in under 20 min or 8 models in one hour and 15 min.

Specs

- Chairside and same-day delivery

- High accuracy and a smooth surface

Material Properties

- Ultimate Tensile Strength:

- Green*: 24 MPa

- Post-Cured: 36 MPa

- Tensile Modulus:

- Green*: 0.8 GPa

- Post-Cured at Room Temperature**: 1.7 GPa

- Elongation at Failure:

- Green*: 14%

- Post-Cured at Room Temperature**: 5%

- Heat Deflection Temperature @ 1.8 MPa:

- Green*: 37ºC

- Post-Cured at Room Temperature**: 43ºC

*Data was obtained from green parts, printed using Form 3, 200 micron, Draft v2 Resin settings, washed in Form Wash and air dried without post-cure.

**Data was obtained from parts printed using Form 3, 200 micron, Draft v2 Resin settings and post-cured with a Form Cure at Room Temperature for 5 minutes.

Application

- Rapid orthodontic aligner production at low cost

Technology/Process

- SLA (Stereolithography)

Model

Material: Formlabs® Model Resin

With Model resin, you can quickly produce high-quality solid, removable die, and implant models with crisp margins and contacts.

Specs

- Fast printing and post-processing

- Rapid return on investment

- Easy to learn, use, and delegate

Material Properties

- Ultimate Tensile Strength:

- Green*: 27 MPa

- Post-Cured: 48 MPa

- Tensile Modulus:

- Green*: 1.1 GPa

- Post-Cured**: 2.3 GPa

- Elongation at Failure:

- Green*: 14%

- Post-Cured**: 4.8%

- Heat Deflection Temperature @ 1.8 MPa:

- Green*: 41ºC

- Post-Cured**: 56ºC

*Data was obtained from green parts on Type IV tensile bars printed on a Form 3 printer with 100 µm Model Resin settings and washed in a Form Wash for 10 minutes in ≥99% Isopropyl Alcohol.

**Data was obtained from parts on Type IV tensile bars printed on a Form 3 printer with 100 µm Model Resin settings, washed in a Form Wash for 10 minutes in ≥99% Isopropyl Alcohol, and post-cured at 60°C for 5 minutes in a Form Cure.

Application

- Crown and Bridge models

- Implant analogue models

- Orthodontic models

- Diagnostic models

Technology/Process

- Stereolithography (SLA)

Castable Wax

Material: Formlabs® Castable Wax Dental

Castable Wax provides accurate, sealed margins and contains 20% wax for reliable casting with clean burnout.

Specs

Printed patterns are strong enough to handle with no post-cure required, allowing for a faster, simpler workflow.

Material Properties

- Ultimate Tensile Strength:

- Green*: 12 MPa

- Tensile Modulus:

- Green*: 220 MPa

- Elongation at Failure:

- Green*: 13%

- Post-Cured**: 4.8%

Burnout Properties:

- Temperature @ 5% ass Loss:

- Green*: 249ºC

- Ash Content (TGA):

- Green*: 0.0 – 0.1%

*Data was obtained from green parts on Type IV tensile bars printed on a Form 3 printer with 100 µm Model Resin settings and washed in a Form Wash for 10 minutes in ≥99% Isopropyl Alcohol.

**Data was obtained from parts on Type IV tensile bars printed on a Form 3 printer with 100 µm Model Resin settings, washed in a Form Wash for 10 minutes in ≥99% Isopropyl Alcohol, and post-cured at 60°C for 5 minutes in a Form Cure.

Application

- Patterns for casting and pressing

- Removable partial dentures

- Crowns

- Bridges

Technology/Process

- SLA (Stereolithography)

White

Material: Formlabs® White Resin

White Resin captures smooth surfaces and details, making it great for diagnostic and educational models.

Specs

- Great details

- Smooth, matte surface finish

- No post-curing necessary

Material Properties

- Ultimate Tensile Strength:

- Green*: 38 MPa

- Post-Cured**: 65 MPa

- Tensile Modulus:

- Green*: 1.6 GPa

- Post-Cured**: 2.8 GPa

- Elongation at Failure:

- Green*: 12%

- Post-Cured**: 6.2%

- Heat Deflection Temperature @ 264psi:

- Green*: 42.7ºC

- Post-Cured**: 58.4ºC

*Data and specs were obtained from green parts printed using Form 2 SLA printer, 100 microns, clear settings, without additional treatments.

**Data was obtained from parts printed using Form 2, 100 μm, clear settings and post-cured with 1.25 mW/cm² of 405 nm LED light for 60 minutes at 60°C.

Application

- Diagnostic Models

Technology/Process

- Stereolithography (SLA)

Soft Tissue Starter Pack

Create your Soft Tissue Resin in the customizable dark, medium, and light pink shades for producing soft tissue for implant models and gingiva masks.

Specs

- Ultimate Tensile Strength:

- Green: 3.7 MPa

- Post-Cured: 8.9 MPa

- Stress at 50% Elongation:

- Green: 1.5 MPa

- Post-Cured: 3.1 MPa

- Stress at 100% Elongation:

- Green: 3.5 MPa

- Post-Cured: 6.3 MPa

- Elongation at Break:

- Green: 100%

- Post-Cured: 120%

- Shore Hardness:

- Green: 70 A

- Post-Cured: 80 A

Data was obtained from parts printed using Form 3, 100 μm, Flexible 80A settings, washed in Form Wash for 10 minutes and post-cured with Form Cure at 60° for 10 minutes.

Application

- Soft tissue for implant models

- Gingiva masks

Technology/Process

- SLA (Stereolithography)

Digital Denture

Material: Formlabs® Digital Denture Base Resin & Denture Teeth Resin

Digital Denture Base Resin and Denture Teeth Resin are biocompatible Class II devices.

Specs

Denture Teeth:

- Flexural Strength: >50 MPa (post-cured)

- Density: 1.15 g/cm³ < X <1.25 g/cm³

Denture Base:

- Flexural Strength: >65 MPa (post-cured)

- Density: 1.15 g/cm³ < X <1.25 g/cm³

Biological testings:

- Non-mutagenic

- Non-cytotoxic

- Not induce erythema or edema reactions

- Not a sensitizer

- Not cause systemic toxicity

Application

- Dental professionals can produce 3D-printed, biocompatible dentures accurately and reliably.

Technology/Process

- SLA (Stereolithography)

Surgical Guide

Material: Formlabs® Surgical Guide

Surgical Guide Resin is a Class I, CE certified resin for biocompatible applications including 3D printing dental surgical guides for implant placement.

Specs

Post-cured* Material Properties:

- Elongation: 12%

- FlexuralStrength: > 102 MPa

- Flexural Modulus: > 2400 MPa

*Data for post-cured samples were measured on Type IV tensile bars printed on a Form 2 printer with 100 µm Surgical Guide Resin settings, washed in a Form Wash for 20 minutes in ≥99% Isopropyl Alcohol, and post-cured at 60°C for 30 minutes in a Form Cure.

Application

- Surgical Guides

- Device Sizing Templates

- Drilling Templates

- Pilot Drill Guides

Technology/Process

- SLA (Stereolithography)

Custom Tray

Material: Formlabs® Custom Tray Resin

Custom Tray resin is a production-ready material to print impression trays for implants, dentures, crowns, bridges, etc.

Specs

Post-cured Material Properties

- Ultimate Tensile Strength: > 70 MPa

- Young’s Modulus: > 2500 MPa

- Elongation: >3%

- Flexural Strength: ≥ 100 MPa

- Flexural Modulus: ≥ 2600 MPa

- Hardness, Shore A: > 80

Application

- Impression Trays

Technology/Process

- SLA (Stereolithography)

Temporary CB Resin

By: Formlabs®

Temporary Crown and Bridge (CB) resin is a Class IIa material designed to 3D print biocompatible dental prosthetics.

Specs

Mechanical Properties

- Density: 1.4 – 1.5 g/cm³

- Viscosity: 2500 – 6000 MPa

- Flexural Strength (post-cured): ≥ 100 MPa

Temporary CB Resin is a Medical Device as defined in the Medical Device Directive (93/42/EEC) in the EU and in Section 201(h) of the Federal Food Drug & Cosmetic (FD&C) Act.

Application

It is a tooth-coloured material that can print at 50-micron layer line resolutions to produce fitting temporaries with a smooth surface finish, high resolution, and dimensional stability.

- Bridges (up to 7 units)

- Veneers

- Inlays

- Crowns

- Onlays

Technology/Process

- SLA (Stereolithography)

IBT Resin

Material: Formlabs® IBT Dental

IBT resin is a Class I-compliant and flexible biocompatible material for efficient, accurate dental bracket placement.

Specs

IBT resin prints full arch and quadrant bracket transfer trays quickly using 100-micron layer heights, reducing labour time and enabling higher throughput.

- Ultimate Tensile Strength: ≥ 5 MPa

- Young’s Modulus: > 16 MPa

- Elongation: > 25%

- Hardness Shore A: < 90

Application

- Indirect Bonding Trays

Technology/Process

- SLA (Stereolithography)

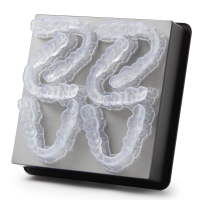

Dental LT Clear

Material: Formlabs® Dental LT CLear

With Dental LT Clear Resin (V2), you can directly print affordable, high-quality occlusal splints in-house.

Specs

- Highly durable and resistant to fracture, this colour-corrected material prints clear and polishes to high optical transparency.

- Resists discoloration over time.

Material Properties

- Flexural Strength at 5% Strain:

- Post-Cured*: 84 MPa

- Flexural Modulus:

- Post-Cured*: 2300 MPa

- Elongation:

- Post-Cured*: 12%

- Hardness Shore D:

- Post-Cured*: 78, Shore D

*Data was obtained on post-cured samples printed on a Form 3B printer with 100 µm Dental LT Clear Resin (V2) settings, washed in a Form Wash for 20 minutes in 99% Isopropyl Alcohol, and post-cured at 60°C for 60 minutes in a Form Cure.

Application

- Occlusal guards

- Splints

Technology/Process

- SLA (Stereolithography)

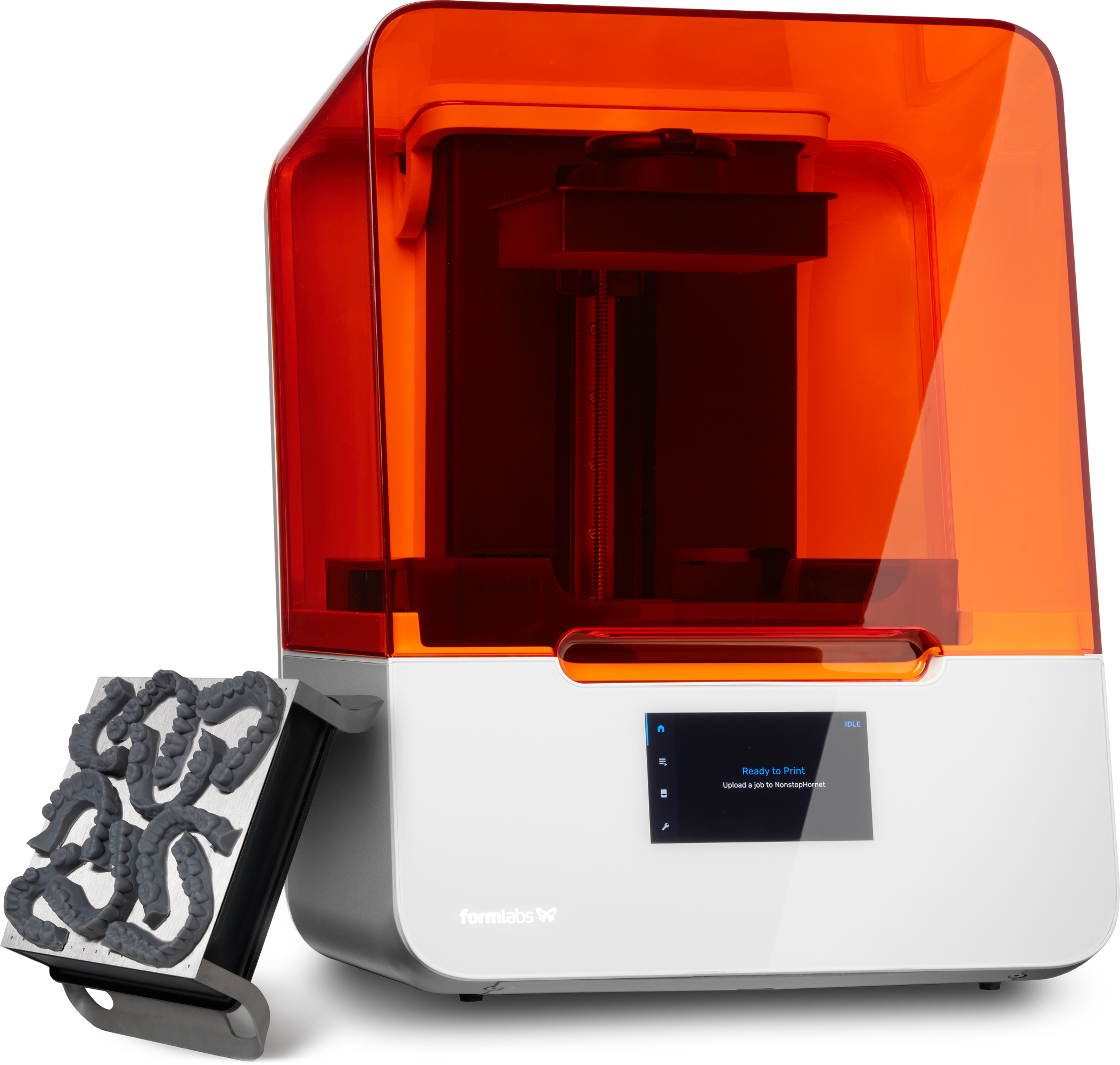

Formlabs® Dental Printers Comparison

From 3B+ |

Form 3BL |

|

Build Volume

|

14.5 × 14.5 × 18.5 cm 5.7 × 5.7 × 7.3 in |

33.5 × 20 × 30 cm 13.2 × 7.9 × 11.8 in |

XY Resolution |

25 microns | 25 microns |

Laser Power |

1x 250 mW laser | 2 x 250 mW laser |

Weight |

17.5 Kg / 38.5 lbs | 54.4 Kg / 120 lbs |

Printer Dimensions

|

40.5 × 37.5 × 53 cm 15.9 × 14.8 × 20.9 in |

77 × 52 × 74 cm 30.3 × 20.5 × 29.1 in |

Print Capacity |

Up to 9 models per print job Up to 60 models per day |

Up to 50 models per print job Up to 200 models per day |

Validated Indications |

|

|

FormFACTS |

Form 3B+ is ideal for:

|

Form 3BL is ideal for:

|