NEO Lab, a family-owned digital orthodontic lab in Andover, Massachusetts, and their 120 employees work with about 3,000 orthodontic and pediatric dental clinics around the country.

The Stratasys team met with the NEO Lab’s CEO and co-owner, Christian Saurman, to discuss about how time-consuming and messy it is to create acrylic devices using a traditional separator liquid because it requires careful application, more product and it tends to bleed around the model. The drying process is also longer and because it’s hard to remove the appliance from the model, the model can easily crack.

A revolutionary solution was about to emerge for a natural separation to release the acrylic from the PolyJet printed support hence, the brain-storming evolved into the development of the Stratasys Separator Digital Materials (DM).

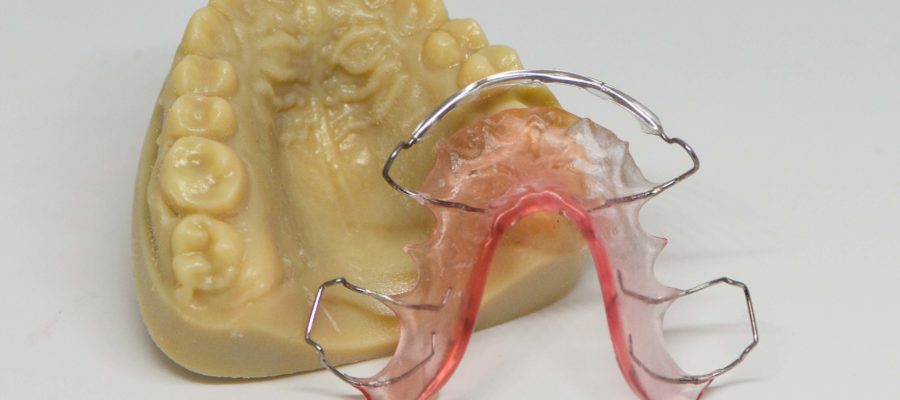

Separator DM infuses with the model resin, easing the separation of the acrylic device from the model — making the removal of wax and acrylic residues easy — resulting in better surface quality and decreased manual labor.

“During production, we’re taking printed resin models and marrying them with acrylic resin. These two will bond, and then we’ve created one big piece of resin that isn’t coming apart,” says Saurman.

When using separator DM, Saurman explained that the only parts that required to be rinsed were the undercuts of teeth and the pedestal, the bottom of the model that sits on the print tray. At NEO Lab, a putty knife is now used to scrape off the support on the bottom and it is post-processed and ready to hit the floor. Whereas before, the model would have been completely encased in support, waterjet it off or put it in the tumbler and tumble off the support.

“For us to be able to print Separator DM, on our J720™ and new J5 DentaJet™, and switching out our 260 line to J5s, we can eliminate all the post-processing that has to happen with these models. We don’t even need the tumbler.” Christian Saurman, CEO NEO Lab