CORiTEC® AM100

imes-icore®

CORiTEC® AM100

Forward-looking hybrid technology for professional dental labs and milling centres

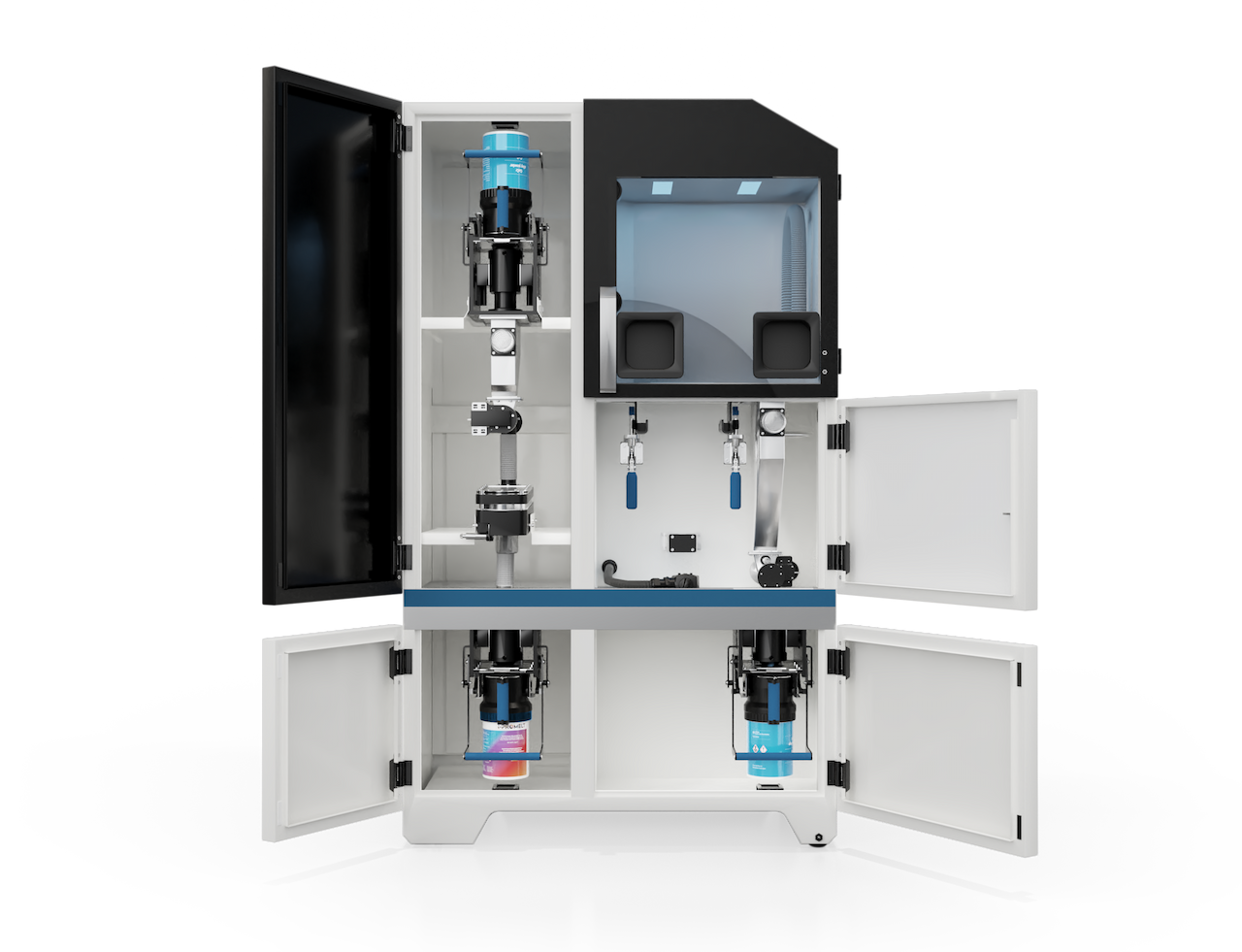

The CORiTEC AM100 metal 3D printer is a fast and affordable entry into additive dental production. It is optimally matched for Cobalt-Chrome dental alloy powder to produce dental prostheses using the laser melting process. In addition, CORiTEC AM100 can 3D print up to 250 units per processing cycle in less than 3 minutes. Last but not least, this hybrid laser powder bed fusion printer is engineered to have an innovative cartridge system which allows for the material to be reused and recycled thanks to the CORiTEC AMpure unpacking station.

High-quality and complex dental constructions through

3D printing & re-milling.

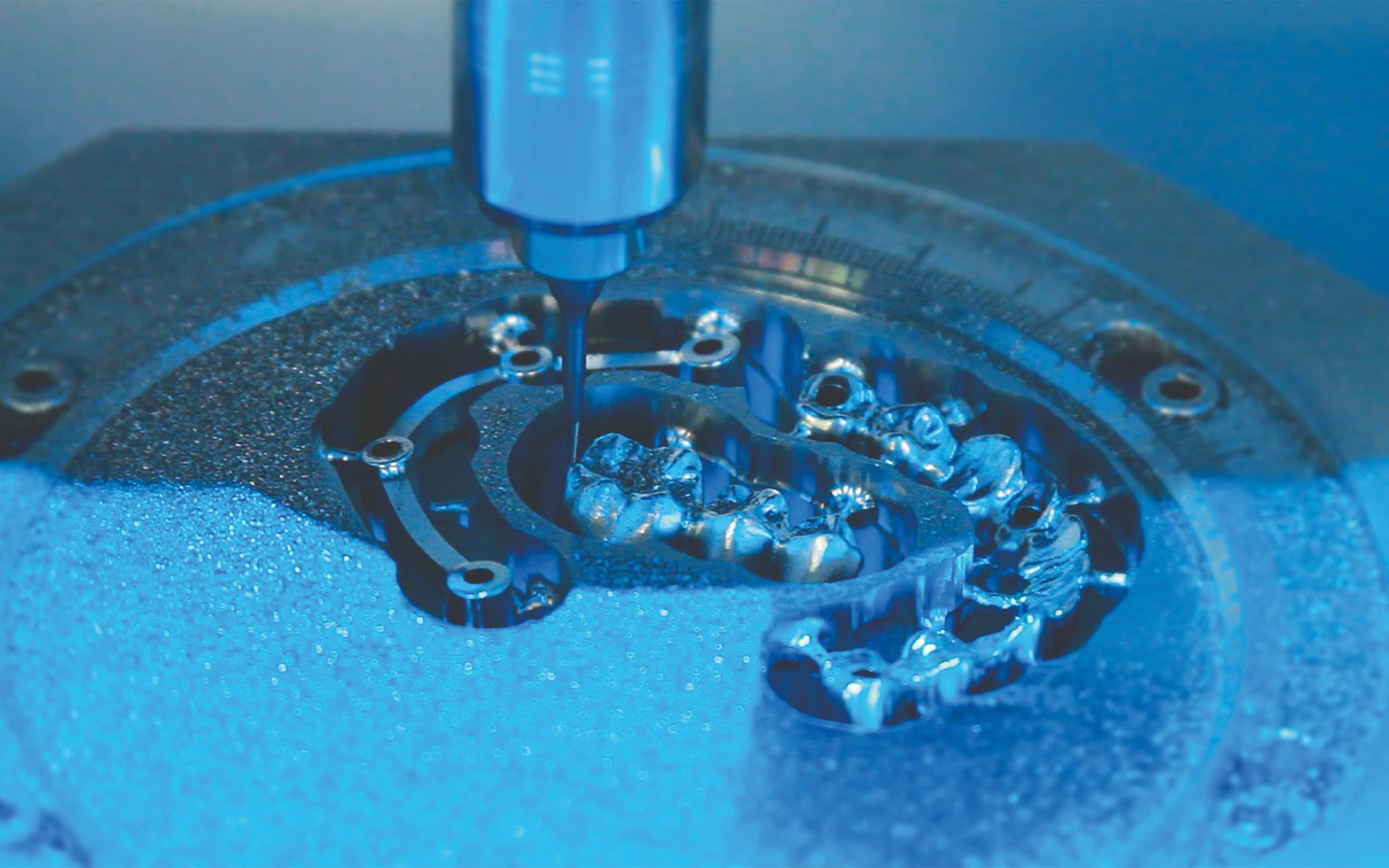

imes-icore’s innovative hybrid technology combines laser powder bed fusion (LPBF) with dental milling. In combination with the CORiTEC 350i and 650i series, you can raise the bar of new standards for high-quality dental prostheses through the re-milling of LPBF units in hybrid technology.

Key Features

Applications

System Highlights & Performance

Laser Powder Bed Fusion System

CORiTEC AM100 works according to the Laser-Powder-Bed-Fusion (LPBF) process. In this process, a 200-watt fiber laser with a focus diameter of 45 µm melts the powder material, layer by layer. This enables the production of the most complex geometries on an area of 150 x 150 x 150 mm, at a speed of up to 3000 mm/s.

Smart Cartridge System

CORiTEC® AMpure is the unpacking station that includes an ultrasonic sieve station for powder preparation. It makes the perfect synergy with the LPBF printing process and the subsequent cleaning of the components without powder contact. The collection of the excess powder in the supply cartridge is fully-automated.

CORiTEC® AM100 HMI

The CORiTEC® AM100 software comes with amazing perks such as a user-friendly operation of the HMI, guided step sequence and an optimal overview through the status display. At any time, the instructions are accessible to the operator.

iCAM AM laser

- Modern and intuitive user interface

- Component analysis and repair through integrated MeshFixer

- Quick preparation of the platform by drag & drop and automated or manual nesting of the components

- Parts can be aligned, scaled and copied automatically or manually

- Critical areas are automatically detected and supported with support structures if necessary

- Perfect hatching parameters for the recommended powder i-ProMelt

Hybrid process: Post-processing milling technique

The hybrid process allows for a post-processing milling technique with the perfect integration in the LPBF process of the CORiTEC 350i / CORiTEC 650i machines. The end result is outstanding fabricated dental restorations and dental prostheses of the highest quality and precision.

Return of Investment

Materials

The i-PROMELT powder is a certified and quality-checked powder for the construction of dental applications. It ensures optimum surface quality with a particle size distribution of 10-30 µm. You can build up highly complex frameworks and form a perfect basis for various veneering ceramics.

Delivery & Usage

i-PROMELT is delivered to the customer, ready to start in the proven cartridge. In other words, the customer can feed the material directly into the process without burdensome filling of cylinders or construction chambers of the machines.

Workflow Insights

Working Process |

Working ProcessDe-powdering + Sieving = Recycling (2 in 1 unpacking and sieving station) |

Unpacking Chamber |

Unpacking ChamberGlove intervention for unpacking without direct powder contact |

Suction System |

Suction SystemIntegrated connection for external suction system |

Material Powder |

Material PowderCobalt Chrome (CoCr) |

Sieving Process |

Sieving ProcessUltrasonic sieve |

Powder Preparation |

Powder PreparationReuse through sieved powder in supply cartridge |

Residual Disposal |

Residual DisposalSeparate for disposal of the oversize powder |

Connection and Consumption |

Connection and Consumption

|

Dimensions and Weight |

Dimensions and Weight

|

Technical Specifications

Printing process |

Printing processLaser Powder Bed Fusion |

Laser power |

Laser power200W |

Production capacity/day |

Production capacity/dayUp to 500 units in cobalt-chrome (CoCr) |

Building volume |

Building volumeUp to 250 dental units |

Building plate |

Building plate150 mm x 150 mm |

Layer height |

Layer height20 – 80 microns |

Focus diameter |

Focus diameter45 μm |

Inert gas |

Inert gasNitrogen |

CAM Software |

CAM SoftwareiCAM AM Laser |