- Dental

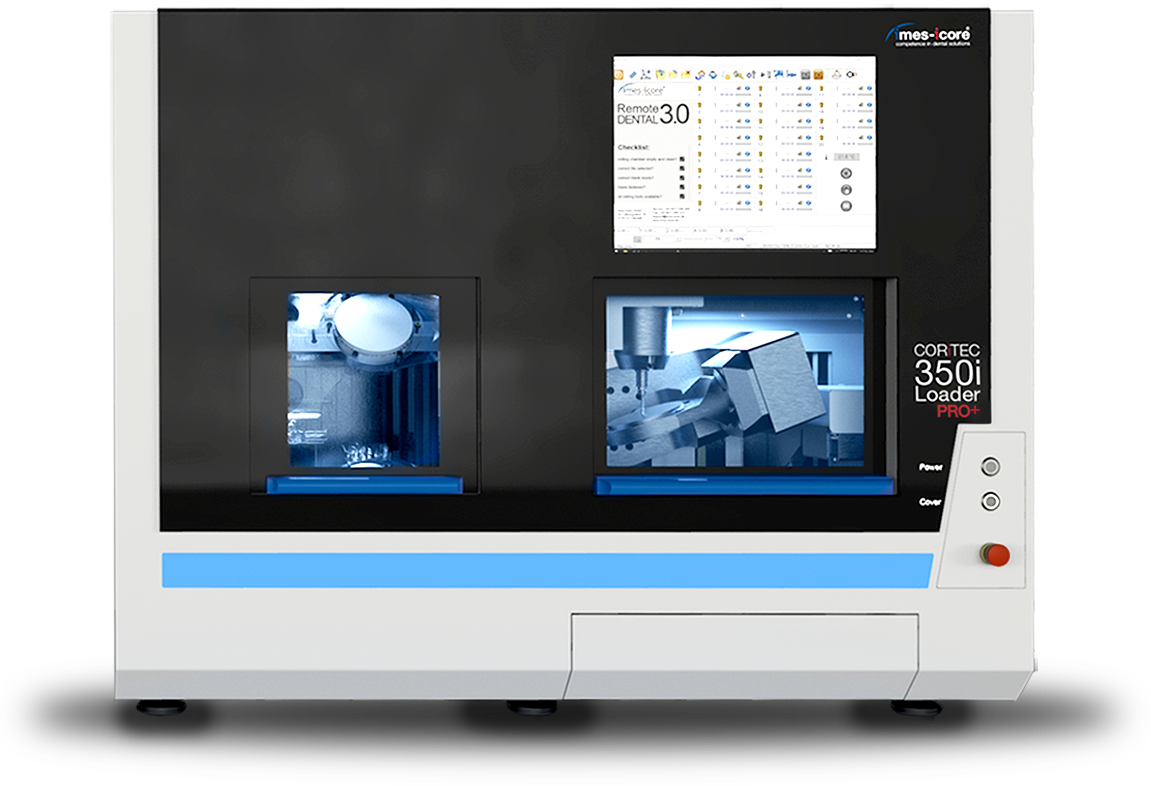

CORiTEC 350i series

CORiTEC 350i series

The CORiTEC 350i series from imes-icore are the ultimate milling machines for dental production. Their unique capabilities and automation systems make them ideal for demanding production environments where accuracy, efficiency, reliability, and throughput are essential. Their robust design allows for the processing of a range of materials including glass ceramics, composites, polymers, pre-milled abutments, and metals.