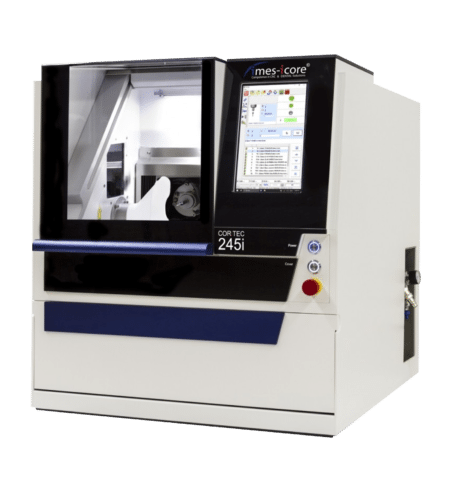

Imes-Icore

CORiTEC 245i/245i Dry

High Precision Through Integrated Temperature Compensation

The CORiTEC 245i and 245i Dry systems establish a productive entry into dental CAD/CAM production. With the ability mill materials like zirconium dioxide or PMMA it becomes a great price/performance solution or a great complimentary system in larger labs.

Optimal Price to

Performance Ratio

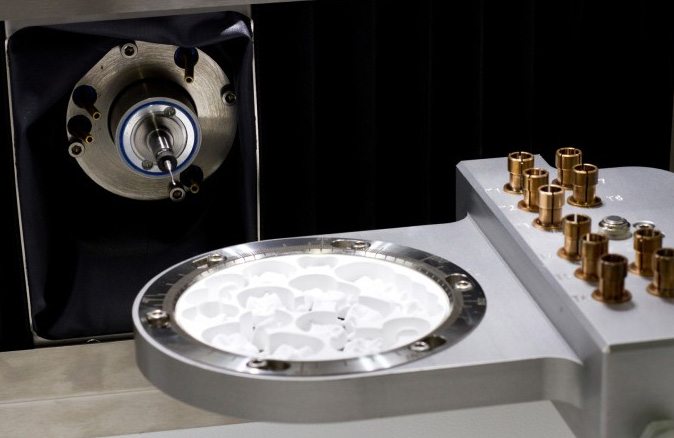

The CORiTEC245i/245i Dry has the perfect price to performance ratio among dental milling machines. Most restorations can be produced inexpensively from materials such as Zirconium Dioxide or PMMA. All commercially available blanks with 98mm or 98.5mm diameters can be used.

CORiTEC 245i/245i Dry Key Highlights

Features that Drive Productivity

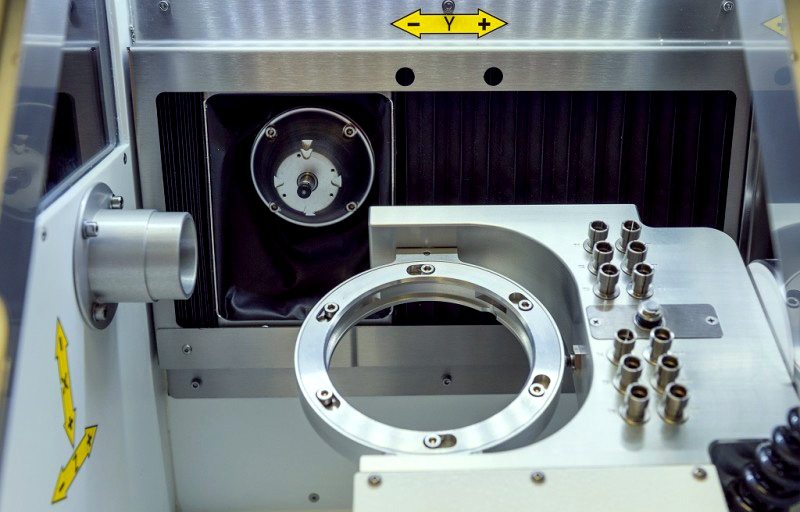

The CORiTEC 245i and 245i Dry come loaded with features that make the milling process seamless and worry-free. The automatic compressed air and coolant monitoring along with the extraction system removes excess material, and ensures your mill runs without failure. High resolution and high performance micro-step controllers guarantee accurate results every time. This makes the 245i & 245i dry a great compact solution for all lab sizes.

Cooled, Controlled and Compact

The CORiTEC 24i and 245i Dry are compact units equipped with an air purge system and cooling nozzles for wet processing, right in the spindle holder. The integrated cooling circuit for cooling lubricant and automatic coolant monitoring allow for the processing of materials like Zirconium Dioxide, PMMA, Wax, Plastics, and grindable block materials, all in one compact unit.

CORiTEC 245i/245i Dry Specifications

# of Axles & Machining Type |

# of Axles & Machining Type4 axes, simultaneous machining |

Max. Tilt Angle (Rotary Axis) |

Max. Tilt Angle (Rotary Axis)A-axis +/- 30 degrees |

Wet Processing |

Wet ProcessingIntegrated only in CORiTEC 245i |

Spindle Max. |

Spindle Max.60,000 rpm / 0.4kW |

Axle Drives |

Axle DrivesMicrostep motors |

Tool Fitting |

Tool Fitting3mm shaft |

Tool Changer |

Tool Changer10-fold |

Workpiece Changer |

Workpiece Changermanual |

Weight |

Weight85kg |

Width x Depth x Height |

Width x Depth x Height520 x 550 x 650mm |

Main voltage/frequency/power |

Main voltage/frequency/power100V-240V/50-60Hz/800W |

Compressed Air Supply |

Compressed Air Supply6-9 bar constant supply, 50 litres/minute |

Materials |

Materialszirconium dioxide, alimunium oxide, PMMA, plastics, composites, wax, glass ceramics (only 245i), hybrid ceramics (only 245i dry) |

Compatibility |

Compatibility98mm/98.5mm blanks CAD/CAM blocks (3 fold adapter), Lava frames |