PolyJet 3D Printing Technology Overview

PolyJet technology is renowned for its outstanding realism and breathtaking aesthetics. The technology works similarly to traditional inkjet printing, but instead of jetting ink onto paper, a print head jets liquid photopolymers onto a build tray where each droplet cures in a flash of UV light.

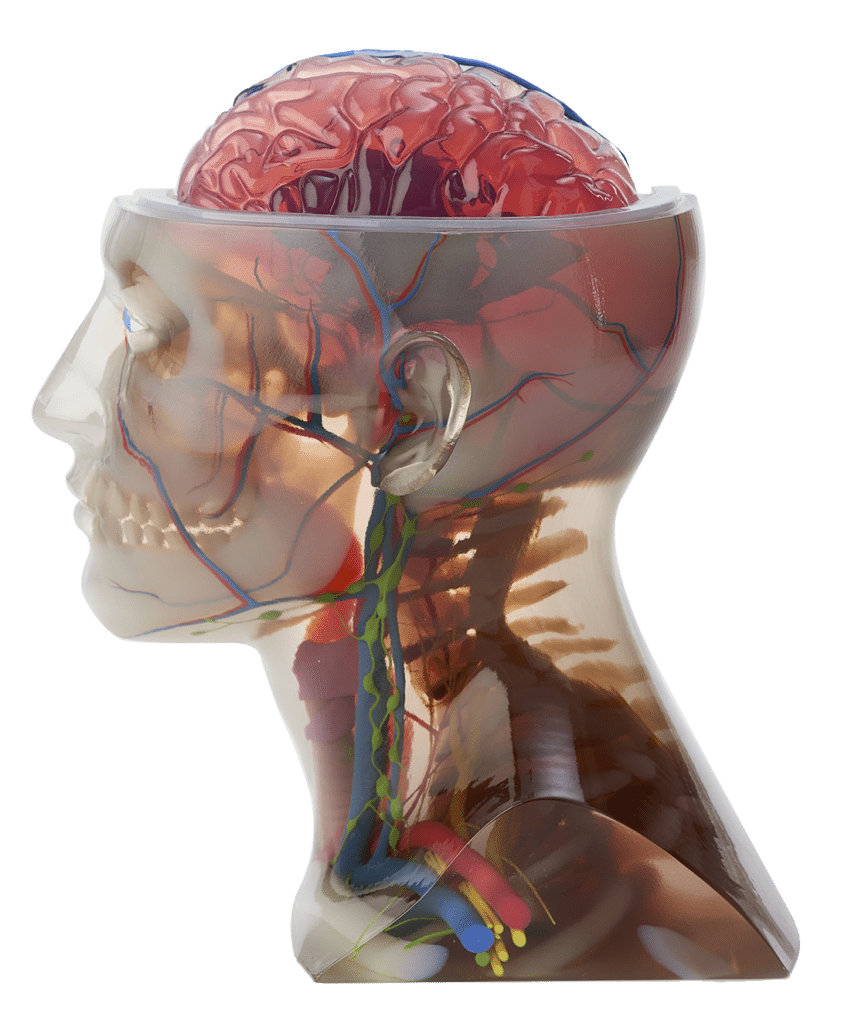

Every PolyJet 3D Printer offers sharp precision, smooth surfaces and ultra-fine details. And, by combining a variety of photopolymers in specific concentrations and microstructures the most sophisticated PolyJet systems can simulate everything from plastics and rubber to human tissue — and produce a full gamut of colors. Dental and Orthodontic Lab owners use PolyJet technology to complete their digital workflow and remove traditional messy and inefficient processes in model production. With PolyJet technology you can produce models in-house directly from intraoral scan and CAD data, cutting days off delivery time. With 16 micron layer resolution and industry leading accuracy you can produce crown and bridge models, implant models and surgical guides, cast partials and an array of orthodontic appliances

Synonyms and similar technologies: multijet printing, photopolymer jetting

Watch the video to see how PolyJet 3D printing technology is being used in digital dentistry

How Polyjet Works

Polyjet 3D printing technology works by jetting layers of curable liquid photopolymer onto a build tray.

- Pre-Processing: Preparation software determines the arrangement of photopolymers to be cured and support material from a native 3D CAD file automatically.

- Production: Polyjet printers instantly cure the droplets of liquid photopolymer using UV. Thin layers accrue onto the build tray to create the 3D part(s). Where support is needed, the printer will jet removable support material.

- Support Removal: Material is easily removable by hand, with water or in a solution bath. No post-curing is required as the 3D printed part is ready to handle straight off the build tray.

Benefits of PolyJet 3D Printing

Printed parts with Polyjet technology are smooth, polished and accurately detailed.

- Polished, smooth and detailed prototypes that simulate end use parts.

- Detailed and precise parts such as realistic teeth and gums, implant models, and even maxillofacial models

- Create complex shapes, intricate details and delicate features.

- Integrate a wide variety of materials and colors into individual models for unmatched efficiency.