The impact of 3D printing, or additive manufacturing, on dentistry is undeniable. Among the overarching benefits for dental appliances, additive manufacturing allows for more accurate appliances, greater customization, faster turnaround times and lower costs. All of which help improve patient satisfaction.

But one of the fascinating benefits of 3D printing in dentistry is the number of ways it can help. Yes, it can produce almost exact duplications of patients’ teeth. And highly accurate appliances, including dentures, bridges and implants. But, additive manufacturing can also improve the placement of those appliances.

Surgical Guides for Implants

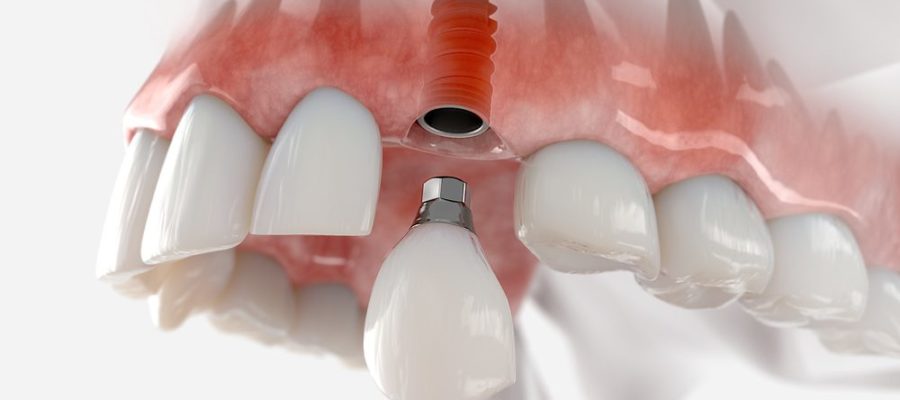

If a patient is missing a tooth or needs a tooth extraction, dental implants can return the patient’s smile and dental function. One of the processes in creating and placing an implant is to scan and x-ray the area that requires the implant. Dentists use the x-ray to determine the best location for the implant. They take into consideration the patient’s bone structure and quality, and other factors, including the location of nerves and blood vessels.

The dentist also determines the length and width of the implant and the depth and angulation of its placement.

The exact placement of the implant is so crucial, dentists use surgical guides to ensure correct positioning. Surgical guides fit over the patient’s teeth that are adjacent to the location of the implant.

3D Printing Dental Surgical Guides

Dentists can use the same data collected during the implant scan and x-ray to 3D-print a tailor-made surgical guide. Importantly, the guide’s accuracy is much greater than if it was made using traditional manufacturing techniques. Printing the guide to more precise specifications improves the placement of the implant and the outcomes of the implant.

To learn more about 3D scanning in dentistry, check out our recent article The Benefits of Using An Intraoral Scanner.