- CAD Cam Design, Dental

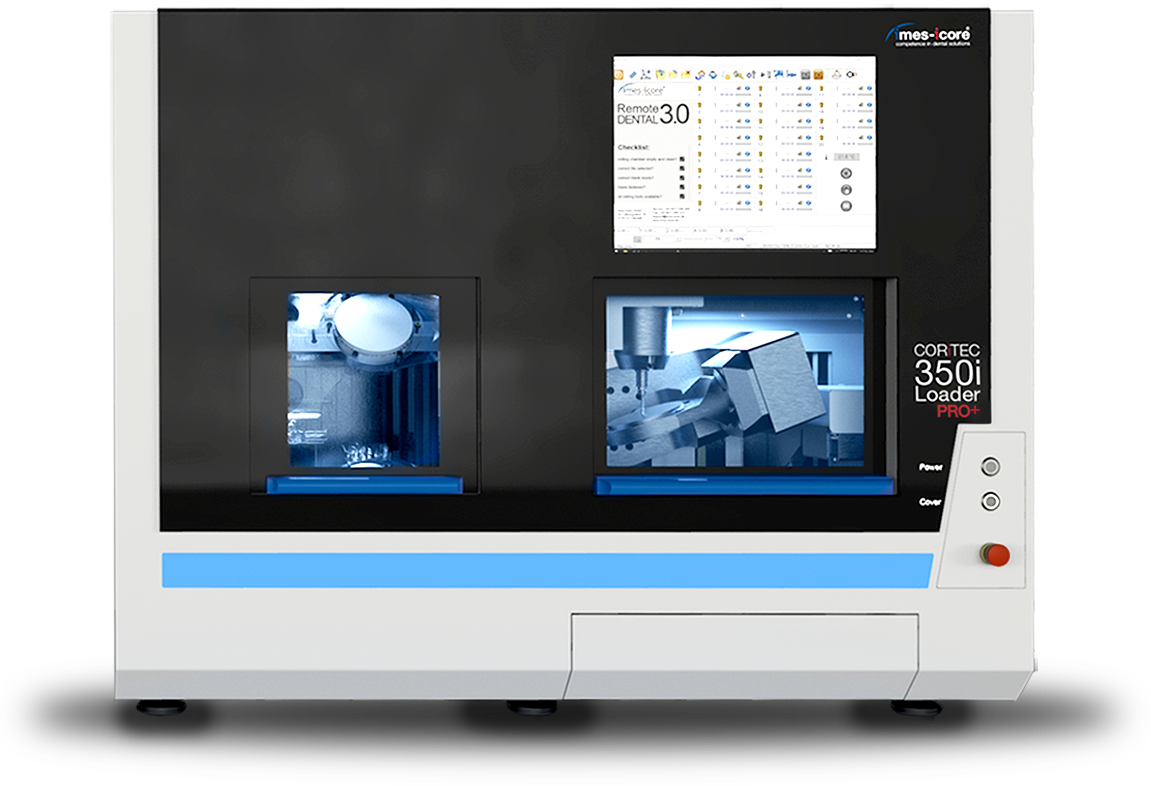

CORiTEC® 350i X PRO series

CORiTEC® 350i X PRO series

The CORiTEC 350i X PRO series combines state-of-the-art control technology and drive components with optimally coordinated parameters. This reduces the milling time by up to 50% and achieves perfect surface quality. The PowerClamp zero-point clamping system offers four times the XtraPower clamping force, which increases rigidity and reduces vibration, resulting in a quantum leap in performance. The 3 kW milling spindle meets the highest demands for surface quality.