Stratasys J5 DentaJet 3D Printer

THE STRATASYS

J5 DENTAJET

Load one tray and walk away. More dental parts in a single mixed-tray print with the NEW Stratasys® J5 DentaJet™.

The Stratasys J5 DentaJet is compact in size but powerful in functionality. With a small footprint and a large-capacity rotating tray, the Stratasys DentaJet is designed to maximize efficiency in dental labs. Create more dental parts with the precision, accuracy, and realism given by Stratasys and PolyJet 3D printing technology

Transforming digital dentistry

By fully embracing digital dentistry, labs can grow their businesses, produce exceptional quality models, and shorten turnaround time, all without adding staff or time. The dental labs that recognize the value of 3D printing acknowledge that the next headway is multi-material 3D printing. It’s like having three printers in one. The versatility opens your lab to multiple application offerings. It provides the ability to print a range of cases from implant models with soft tissue and custom-fit surgical guides or aligner setups and indirect bonding trays, or a variety of restoration mock-ups and more, all at the same time. This simplifies the workflow, reduces scheduling burden, and 3D printer management.

Key Features that Drive Productivity

Digital dentistry is happening. We’ll make it happen with you.

Advantages

Small footprint,

big impact

The Stratasys J5 DentaJet™ 3D printer provides high throughput with a small footprint and affordable price. This full-color printer has the capacity to:

- print five materials including three biocompatible resins

- enable highly realistic modeling and marketplace differentiation

- easily remove orthodontic devices from the model due to the Separator Digital Materials.

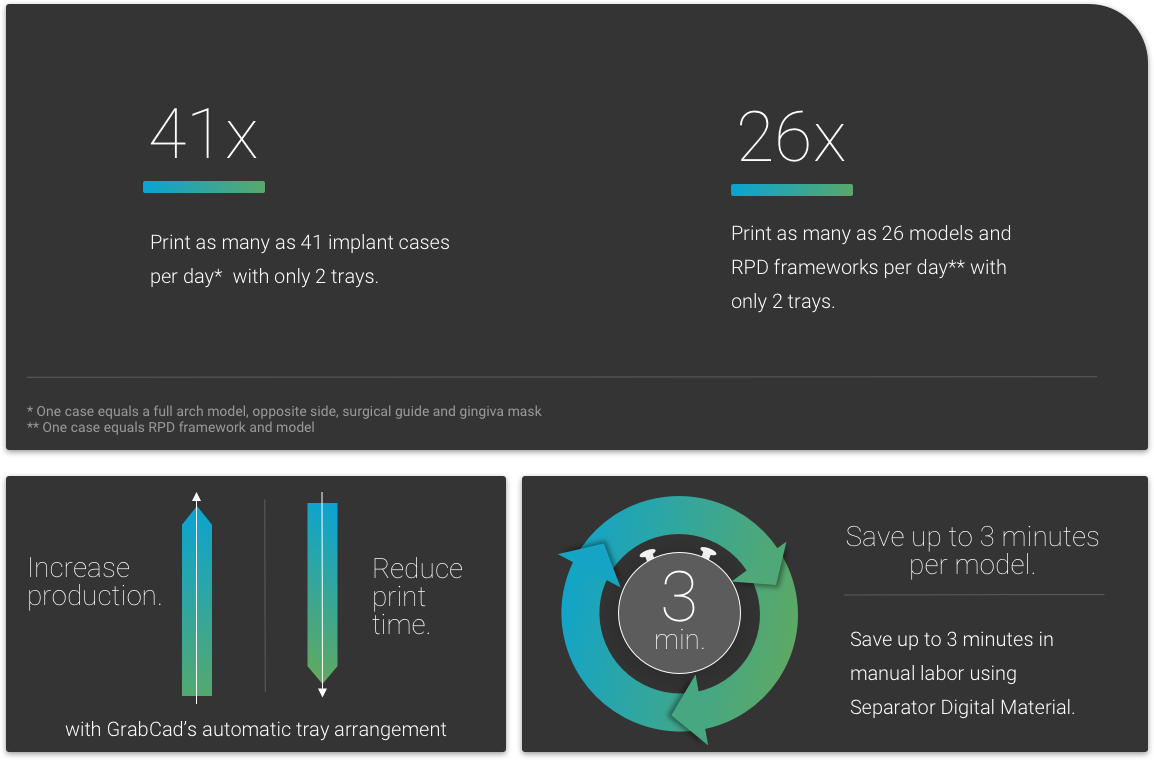

Mixed-tray printing allows full implant cases—model, gingiva mask and surgical guide—on the same tray during the same print. J5 DentaJet offers maximum productivity thanks to its large tray area and the freedom given by unattended operations capabilities.

Harness the power of colour.

- Increase patient acceptance of case presentations — show your patients how their treatment will look before starting work

- Leverage full-color capability to differentiate your lab, improve workflow and tracking, and communicate more information

- Reduce C&B remakes with the only dental printer able to create highly realistic replicas of the patient’s mouth.

The Business Impact of 3D Printing for Dental Labs

NEOLab Integrates 3D Printing Into Digital Workflow

Applications

Crown & Bridge

3D printing eliminates the delays and inaccuracies of manual labor, enabling faster production and higher-quality crown and bridge models with fewer remakes.

Implantology

You can simplify the complexity of implantology by printing the model, surgical guide and soft gingival mask in different materials simultaneously on the same tray. Multi-material 3D printing is ideal for creating implant models that mimic gum textures.

Orthodontics

Formfitting Solutions to Get Teeth, and Your Bottom Line, Aligned

Go straight from intraoral scan to in-house production with a seamless digital workflow. Cut days off delivery times and produce more accurate, comfortable and effective orthodontic appliances. Simplify the creation and service quality with Separator Digital Material, which coats models, making the removal of wax and acrylic residues easy. Expand your lab with new service lines by offering 3D printed indirect bonding trays or producing clear aligners from 3D printed arches. Plus, digital storage allows for appliance production without needing new impressions from patients, saving on space and chair time.

Removables

The Speed, Precision, and Customization to Outperform Traditional Dentistry

Mainstream the manufacturing process of cast chrome partials with automation that cuts down on labor. Predictable and repeatable results reduce patient visits and resets with precise frameworks, denture and partial try-ins produced in less time in smooth, biocompatible materials.

Stratasys J5 DentaJet Specifications

Build Tray Size |

Build Tray Size1,174 cm2 |

Minimum Layer Thickness |

Minimum Layer ThicknessHorizontal build layers down to 18 microns (0.0007 in.) |

Software |

SoftwareGrabCAD Print™ |

Build Modes |

Build ModesHigh Quality Speed (HQS) – 18.75μm |

Model Materials |

Model MaterialsBiocompatible materials• Biocompatible Clear MED610™ • VeroGlaze™ (MED620) • Flexible clear biocompatible material MED625FLX™ Vibrant colours including: • VeroCyanV™ (RGD845) • VeroMagentaV™ (RGD852) • VeroYellowV™ (RGD838) • VeroDent™ PureWhite (DEN847) |

Digital Model Materials |

Digital Model MaterialsUnlimited number of composite materials including:• Over 500,000 colors • Separator Digital Material |

Support Materials |

Support MaterialsSUP711™ (Water Jet removable) |

Machine Dimensions |

Machine Dimensions651 x 661 x 1511mm (25.63 x 26.02 x 59.49 in.) |

Machine Weight |

Machine Weight228 kg (503 lbs.) |

Network Connectivity |

Network ConnectivityLAN - TCP/IP |

Operating Conditions |

Operating ConditionsTemperature 18 – 25 °C (64 – 77 °F); relative humidity 30 – 70% (non-condensing) |

Power Requirements |

Power Requirements100 – 240 VAC, 50 – 60 HZ, 10A, 1 phase |

Regulatory Compliance |

Regulatory ComplianceCE, FCC, EAC |