EnvisionOne Dental

Desktop Health™

EnvisionOne Dental

A Powerful Dental 3D Printing Platform for Labs and Clinics

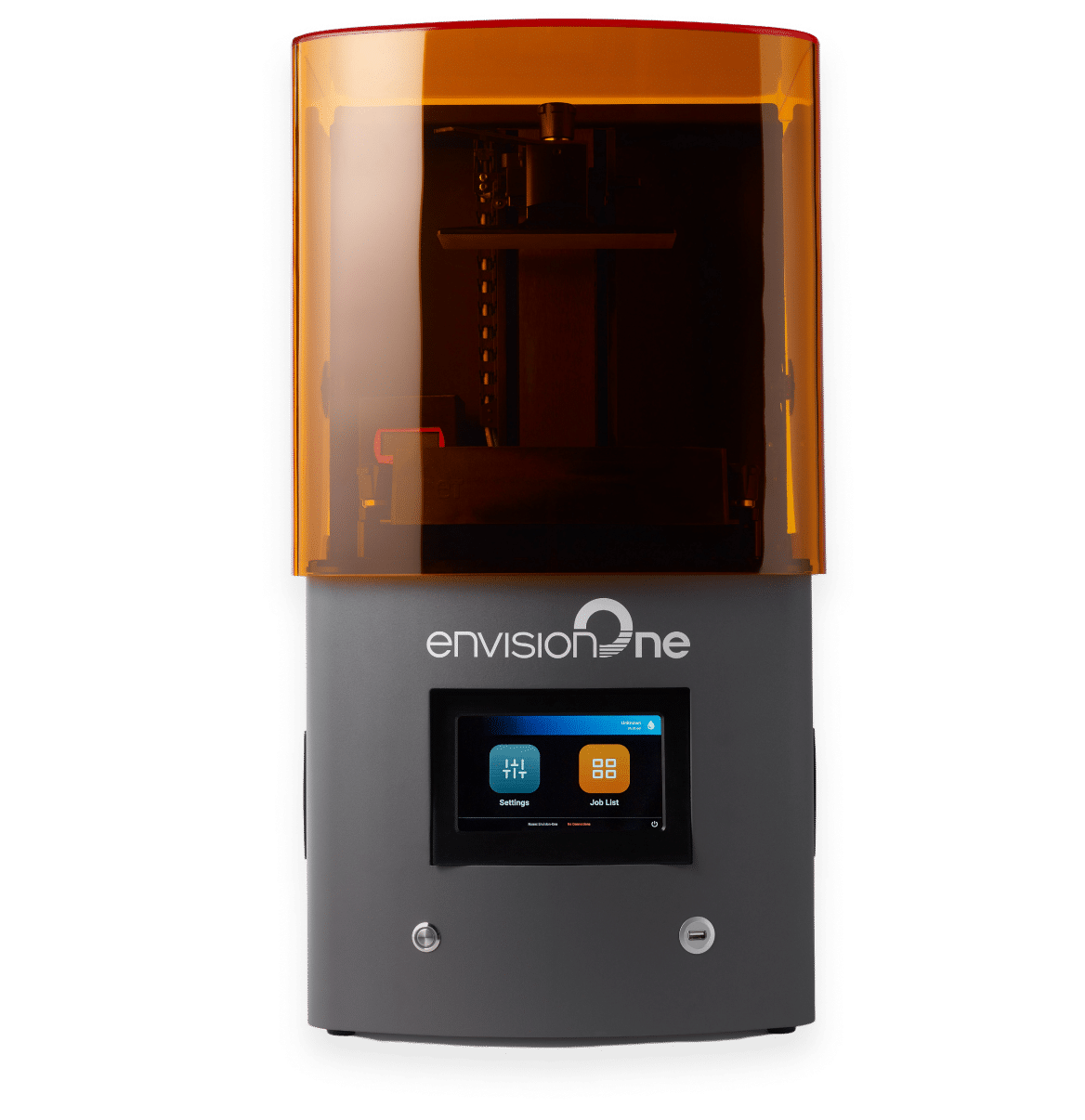

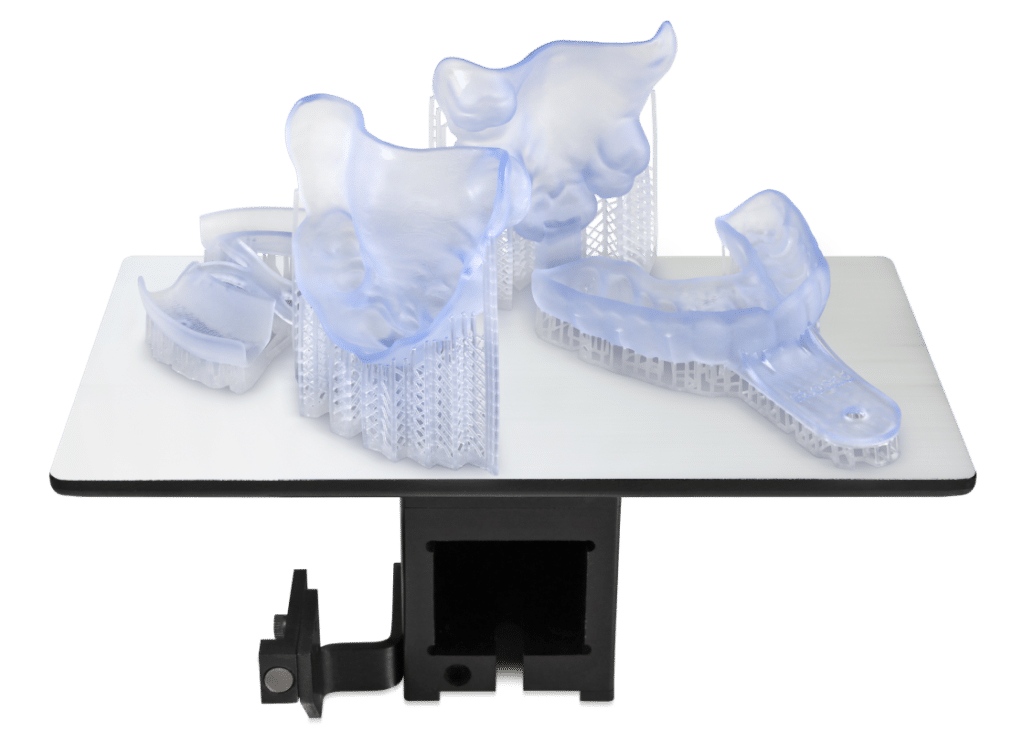

The EnvisionOne™ Dental is the ultimate all-in-one 3D printing solution for dental labs and clinics. Powered by cDLM 3D printing technology, the EnvisionOne is capable of speed and precision with one of the widest portfolios of Health Canada and FDA-cleared 3D printing resins. Discover the benefits of a complete digital workflow and bring high-quality 3D printing in-house today.

Speed and Quality Without Compromise

The EnvisionOne™ dental 3D printer is engineered to deliver a simple and fully integrated 3D printing workflow for your lab or clinic. Powered by continuous digital light manufacturing technology and compatible with a best-in-class range of dental materials, EnvisionOne enables high-speed and precision production for every clinical application.

Features

Intuitive Workflow

Advantages & Benefits

Versatility in Dental Applications

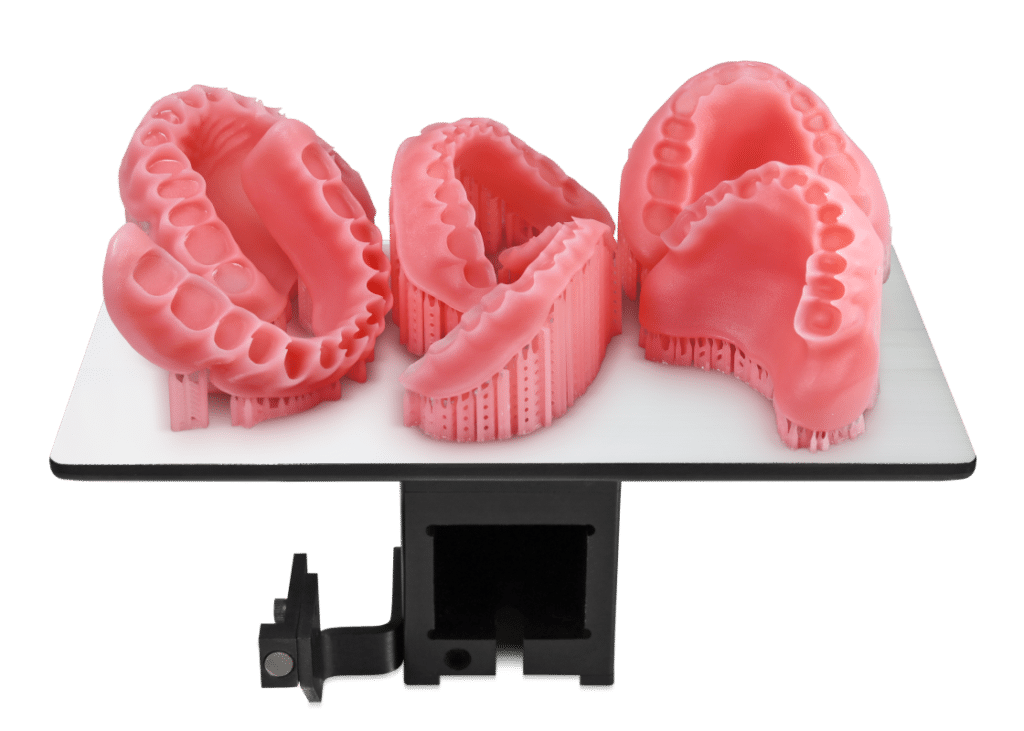

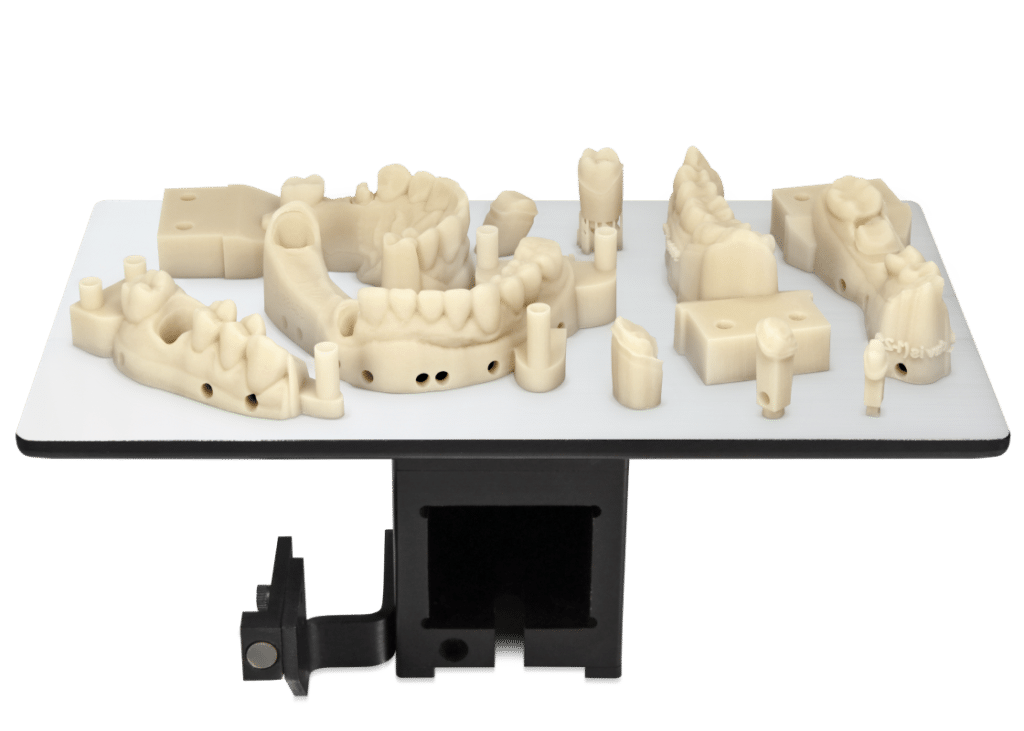

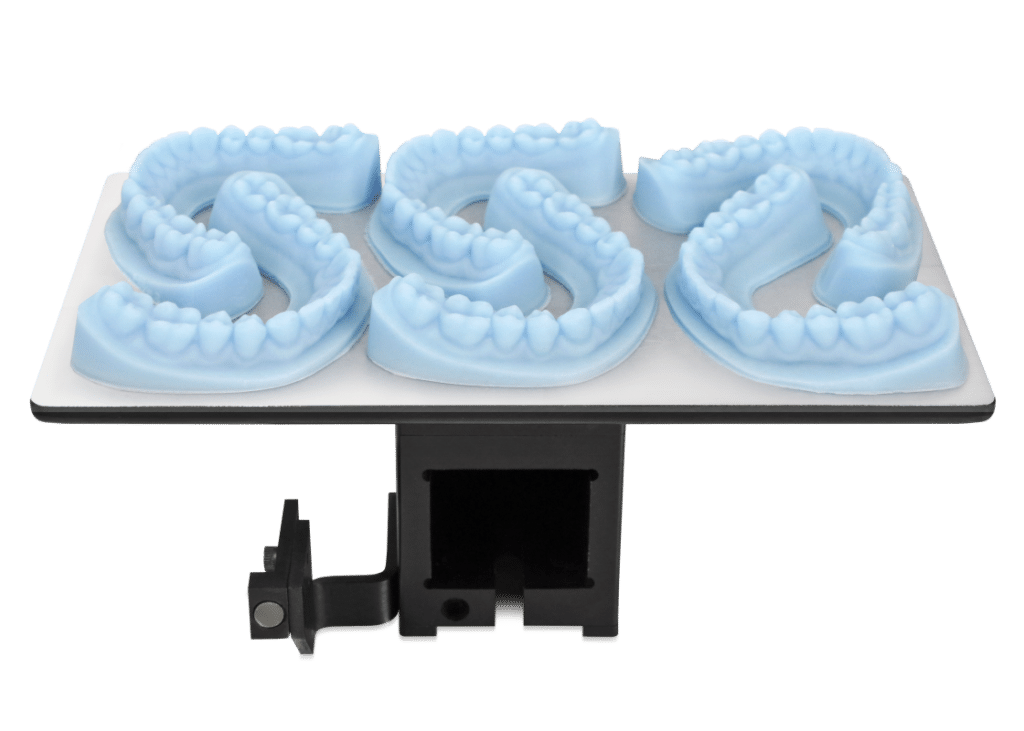

EnvisionOne™ is a desktop 3D printer that can quickly produce bite splints or night guards, dental or orthodontic models, partial dentures, temporary restorations, indirect bonding trays, wax-ups and surgical guides.

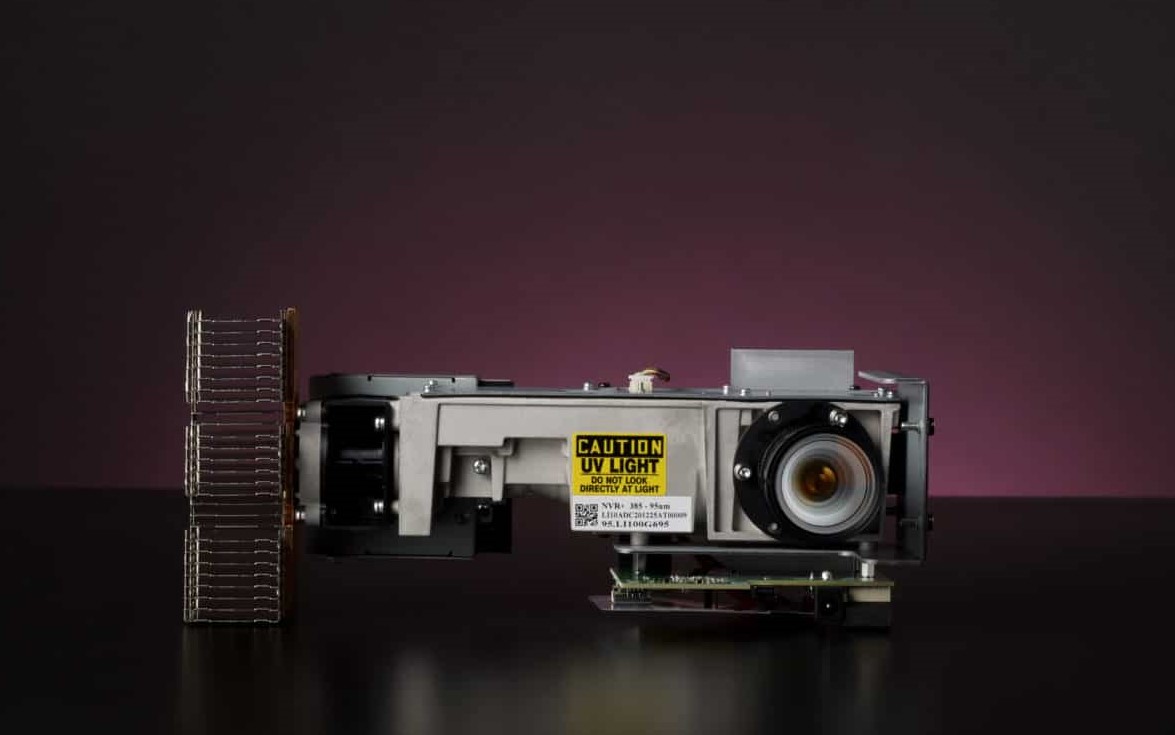

High Accuracy

Across the entire build tray — not just the center.

EnvisionOne™ uses a projector with 385nm wavelength and a specially designed material tray that eliminates the inaccuracies associated with other continuous 3D printing technologies.

Speed

Whether you want to 3D print a tray of 6 models for thermoformed aligners in under 15 minutes or 4 models for thermoformed aligners in about an hour, EnvisionOne is a productivity workhorse.

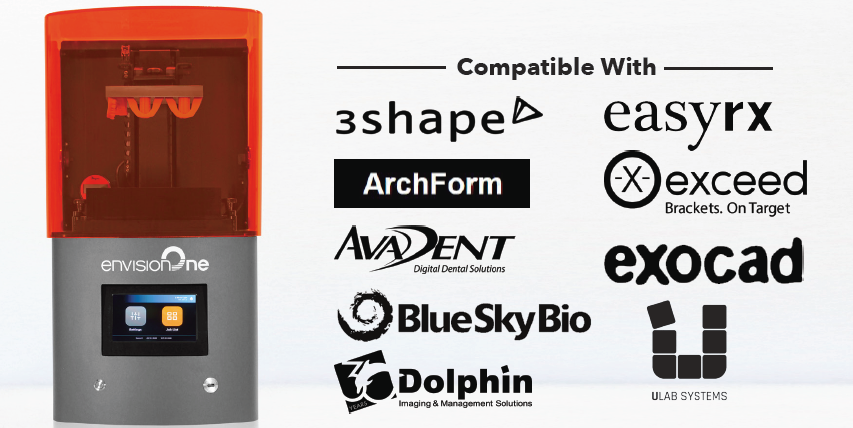

Software Compatibility

Envision One comes with the easiest processing software, Rapid Prototype (RP) Software, ready to deliver optimal results in a minimum of time. It is also compatible with all the leading scanners and software currently on the market.

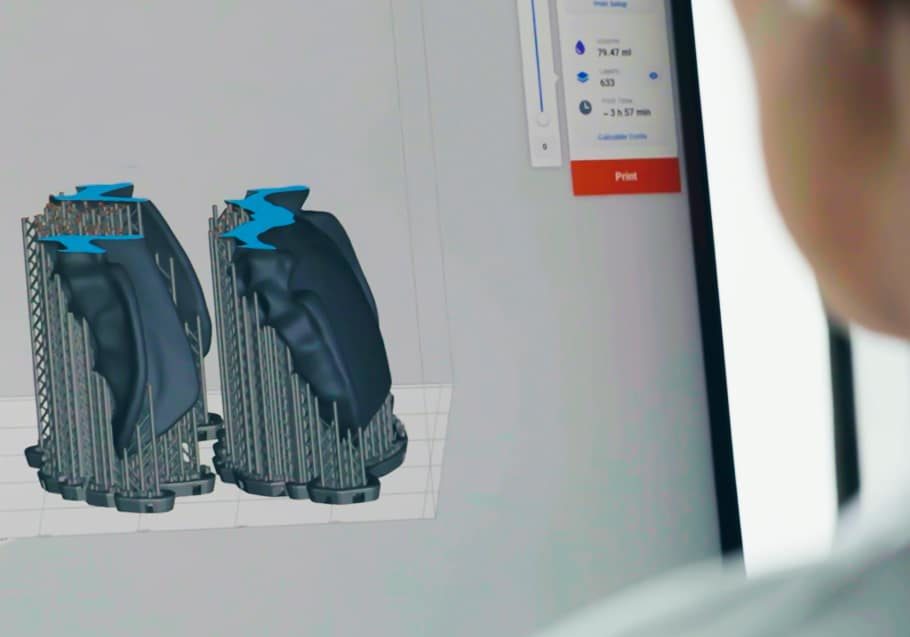

HyperPrint™

Get Ready to Print with One Click.

Rapid Prototype (RP) Software

HyperPrint™ is included in EnvisionTEC’s 3D printers and it’s a complete software design for your dental practice. This easy-to-use software translates CAD design into printable files.

Cost Savings & Competitiveness

With EnvisionOne, the dental and orthodontics practices are more competitive and more aligned to the patients’ needs. The clinicians and labs can rely on low-cost production due to EnvisionOne’s versatility in software, materials and capabilities.

Clean and Cure

Comprehensive Post-Processing Workflow

PWA 2000, PCA 2000, & PCA 4000

Our clean and cure products will make the most of your DLP 3D printing technology offering superior cleaning and curing for exceptional model quality. With powerful light sources and automation built-in, you will have an effortless post-processing experience that yields exceptional dental applications

Materials

Flexcera Base

Premium Denture Base 3D Printing Material

Flexcera Base™ is a light-curable resin for the production of high-impact and removable denture bases.

Specs

- Viscosity @ 30°C: 535 cP

- Shore D: 81

- Izod Notched Impact: 29.6 J/m

- Young’s Modulus:

- 780 MPa (dry material)

- 902 MPa (after immersion in water 2 days at 37°C)

- Ultimate Flexural Strength:

- 90 MPa (dry material)

- 81 MPa

- (after immersion in water 2 days at 37°C)

Application

- Removable denture bases

- Functional dentures

Technology/Process

Continuous Digital Light Processing™ compatible with ETEC and Desktop Health 3D printers.

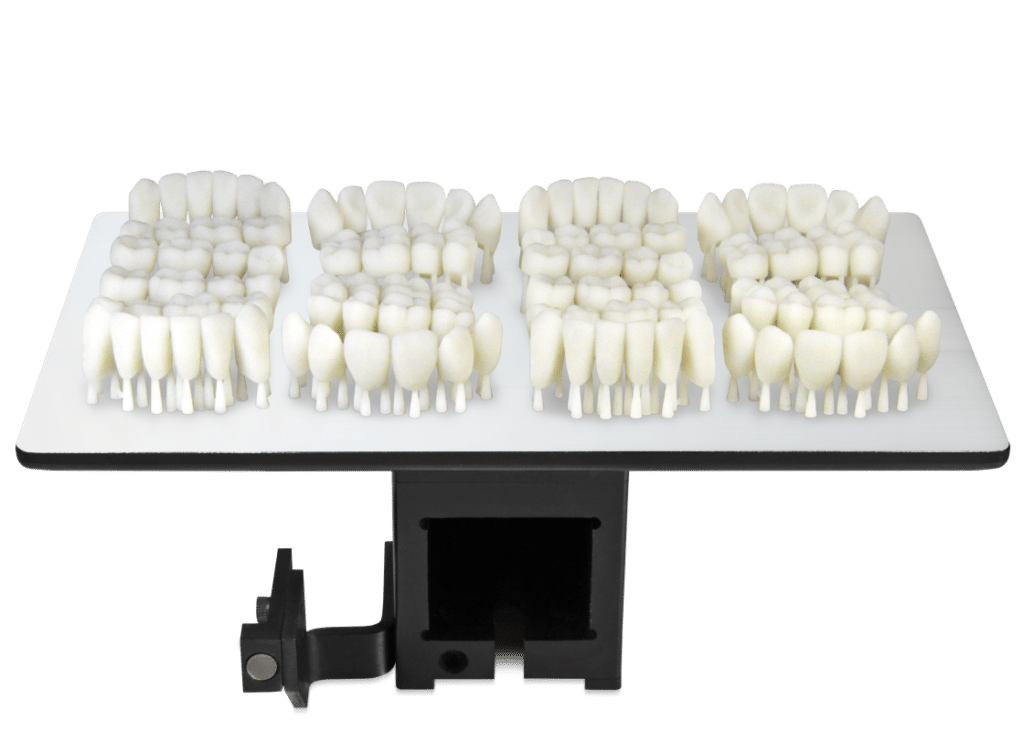

Flexcera Smile

Premium Denture Teeth 3D Printing Material

Flexcera™ Smile is a light-curable resin for the fabrication of high-impact artificial teeth with variable translucency for dentures.

Specs

- Viscosity @ 30°C 660 cP

- Shore D: 89-90

- Izod Notched Impact: 20 J/m

- Heat Deflection Temperature: 58°C @ 1.82 MPa

- Young’s Modulus:

- 1340 MPa (dry material)

- 1330 MPa (after immersion in water 2 days at 37°C)

- Ultimate Strength:

- 67.5 MPa (dry material)

- 68.9 MPa (after immersion in water 2 days at 37°C)

- Strain at Break:

- 16% (dry material)

- 14% (after immersion in water 2 days at 37°C)

- Ultimate Flexural Strength:

- 136 MPa (dry material)

- 125 MPa (after immersion in water 2 days at 37°C)

- Flexural Modulus:

- 3660 MPa (dry material)

- 3300 MPa (after immersion in water 2 days at 37°C)

Application

- Digital Denture Teeth

Technology/Process

Continuous Digital Light Processing™ compatible with ETEC and Desktop Health 3D printers.

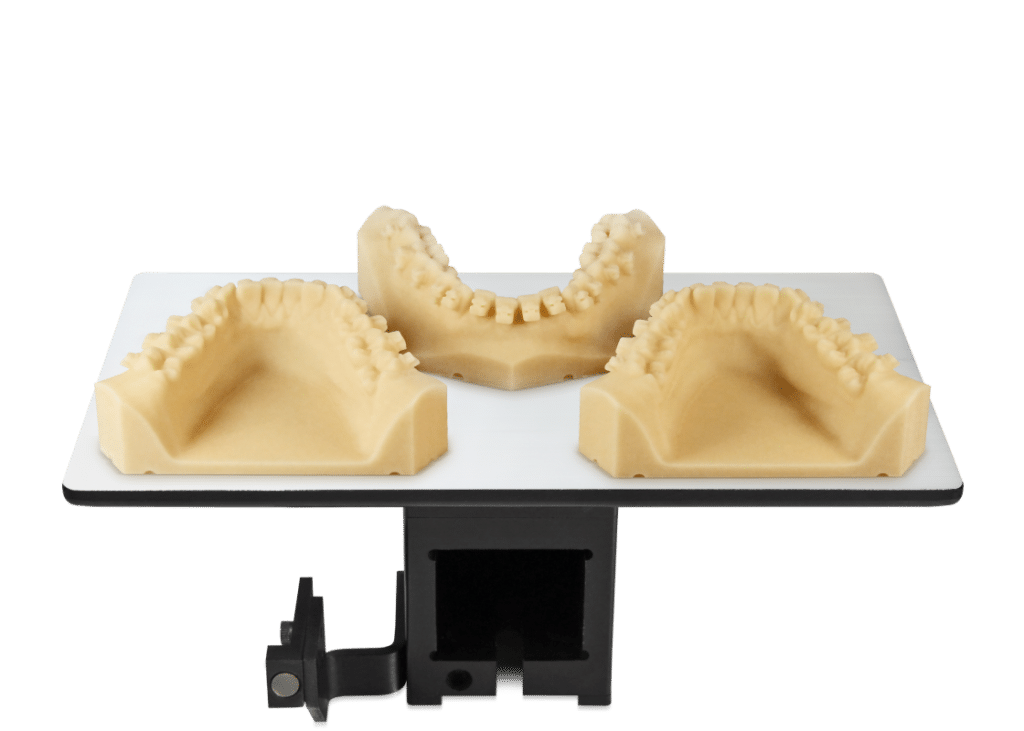

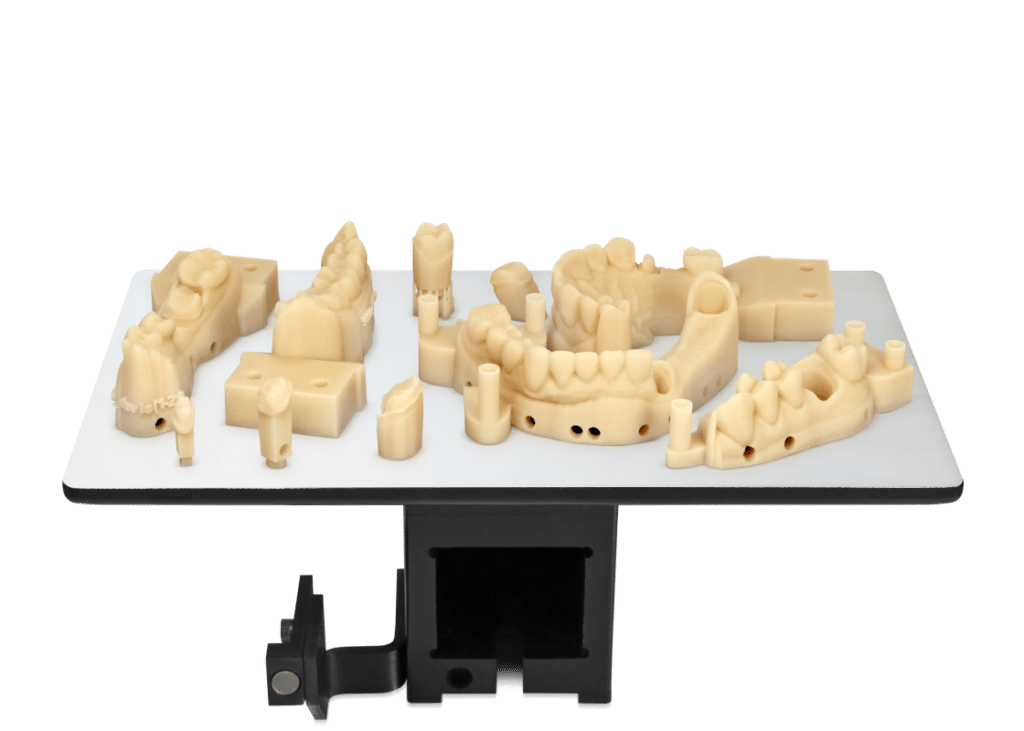

E-Model Beige

Material: E-Model Beige

E-Model Beige printing material for DLP and cDLM 3D printers is the perfect choice for orthodontic models for thermoforming aligners over.

Full Description

A high green strength gives E-Model Beige added strength and stability during the build, resulting in lower shrinkage and curling than similar products. The low viscosity of the liquid material allows for quick and easy cleanup of the models. E-Model Beige produces detailed models, with exceptional surface finish, for precise orthodontic treatment plans.

Specs

- Tensile Strength: 55 MPa

- Elongation at Break: 5.5%

- Tensile Modulus: 2200 MPa

- Flexural Strength: 90 MPa

- Flexural Modulus: 2540 MPa

- Impact: 25J/m

- Heat Deflection Temperature (HDT): 60.5°C at 1.82 MPa

- D Hardness: 83

- Viscosity: 150 cP at 30°C

Application

- Crown and bridge models

- Orthodontic models

- Implant models

- Clear aligner models

- Diagnostic models

Technology/Process

Continuous Digital Light Processing™ & Digital Light Processing used with EnvisionTEC™ 3D printers.

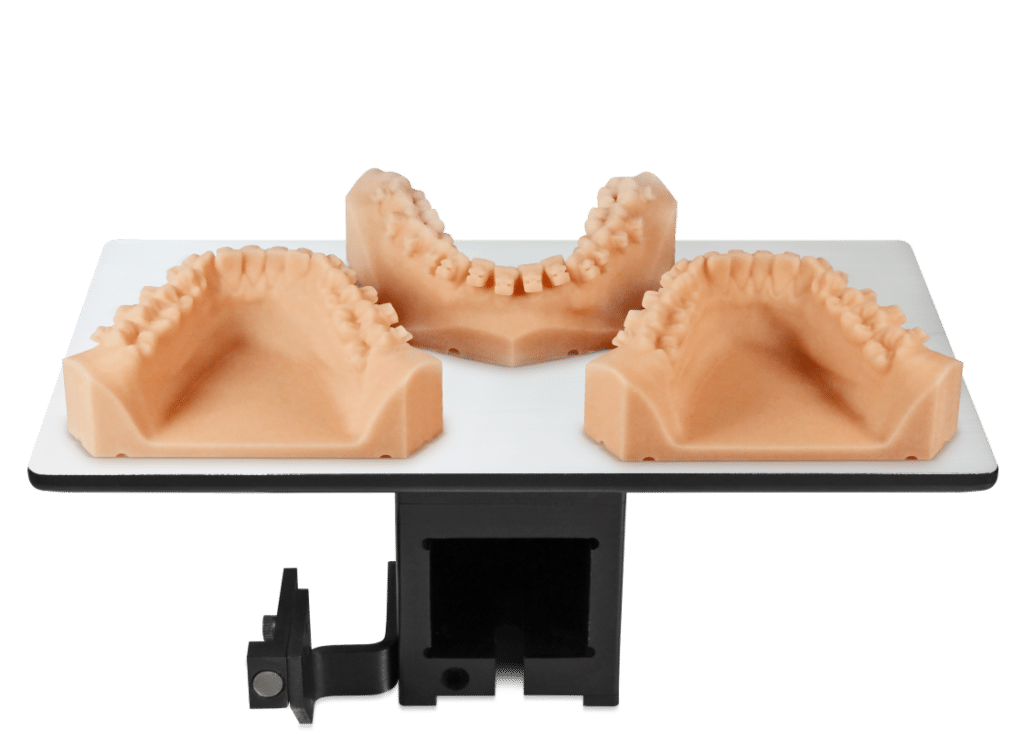

E-Model HS

Material: E-Model HS

E-Model HS material produces models with high accuracy and an exceptional surface finish for a perfect fit.

Full Description

E-Model HS is ideal for orthodontic applications when using a thermoforming technique to produce clear aligners. With the ability to print up to 120 mm/hour, this material is the fastest printing resin on the market today.

Specs

- Tensile Strength: 48.6 MPa

- Elongation at Break: 7%

- Flexural Strength: 2100 MPa

- Hardness: Shore D 83

- Resin Specific Gravity: 1.10 – 1.12 g/cm3

- Print Speed: Up to 120 mm/hour

Application

- Thermoforming models

- Clear aligner models

- Orthodontic appliance models

- Diagnostic models

Technology/Process

Continuous Digital Light Processing™ used with EnvisionTEC™ 3D printers.

E-Guide

Biocompatible certified Class I material

E-Guide is an accurate material for dental modelmaking and clear aligner production. With E-Guide, drill guides can be produced at lower costs.

Full Description

This resin is a biocompatible certified Class I material, developed for the production of high precision surgical drill guides for use in implant surgery. The results produced by combining E-Guide with EnvisionTEC technology are superior to traditional methods of manufacturing implant placement guides.

Specs

- Ultimate Flexural Strength: 79 – 85 MPa

- Flexural Modulus: 2059 – 2030 MPa

- Water Sorption: 30 – 32 µm/mm3

- Water Solubility: 0.5 µm/mm3

- Viscosity @ 30°C: 230 – 330 cP

- Cytotoxicity: Passed ISO 10993-5

- Irritation and skin sensitization: Passed ISO 10993-10

Application

- Surgical guides

- Pilot drill guides

- Drilling templates

- Device sizing templates

Technology/Process

Continuous Digital Light Processing™ used with EnvisionTEC™ 3D printers.

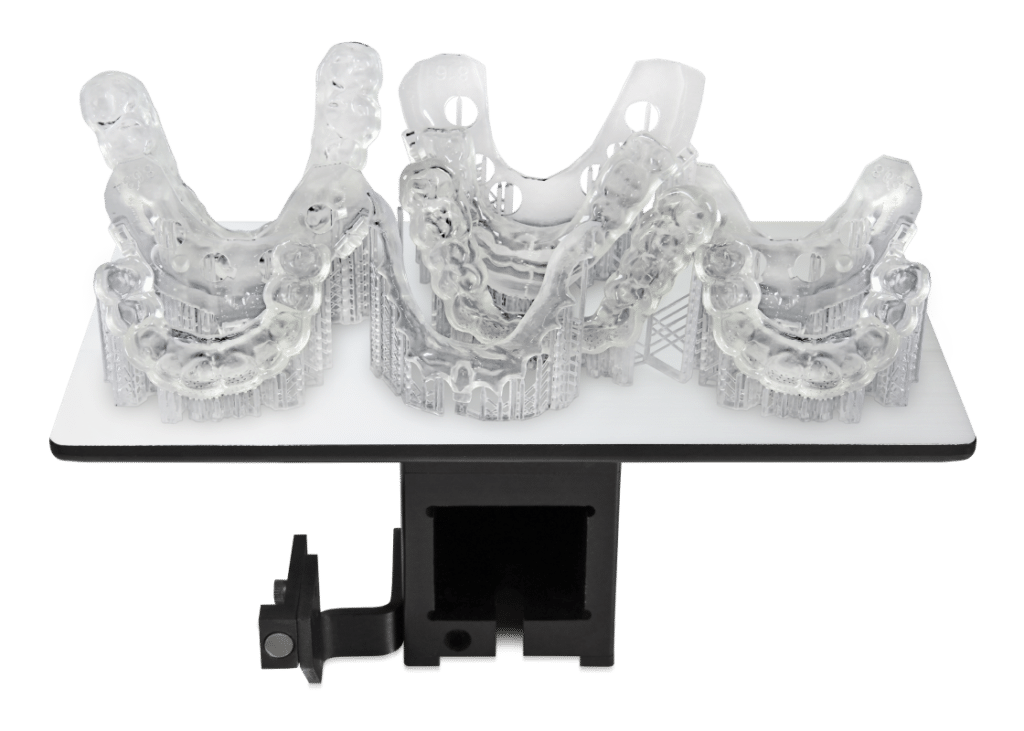

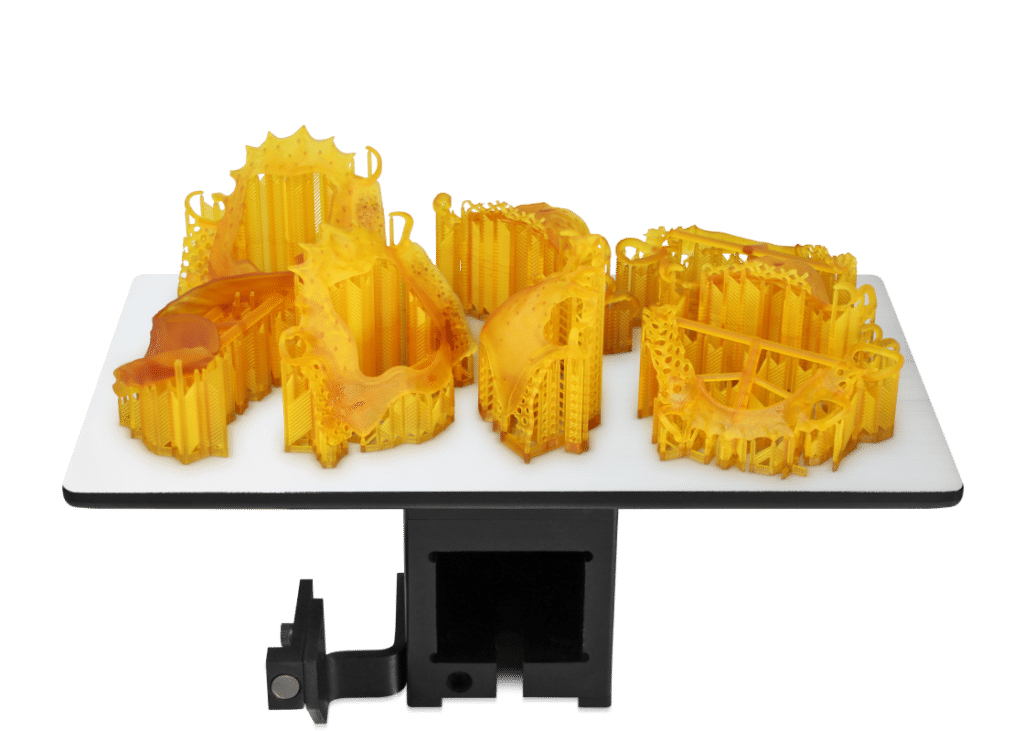

E-Guard

Biocompatible transparent resin

E-Guard is a biocompatible transparent material for the production of accurate orthodontic bite splints and night guards.

Full Description

It is a clear material, allowing for maximum visibility. High-resolution 3D printing allows for a precise fit. The results produced by combining E-Guard with EnvisionTEC technology are superior to traditional methods of manufacturing bite guards and night guards.

Specs

- Ultimate Flexural Strength: 79-85 MPa

- Flexural Modulus: 2050 – 2130 MPa

- Water Sorption, µm/mm3: 30 – 32

- Water Solubility, µm/mm3: 0.5

- Viscosity @ 30°C, cP: 230 – 330

- Cytotoxicity Passed: ISO 10993-5

- Irritation and Skin Sensitization: Passed ISO 10993-10

Application

- Nightguards

- Occlusal guards

- Snoring appliances

- Bite splint

- Bite planes

Technology/Process

Continuous Digital Light Processing™ used with EnvisionTEC™ 3D printers.

Press E-Cast

Material: Press E-Cast

Press-E-Cast is a wax-filled photopolymer material designed for producing wax copings and crowns with highly detailed anatomy and crisp features. It can be pressed into full-contour ceramics.

Full Description

With Press E-Cast it is possible to produce a perfectly fitting multiple unit bridge up to 16 units due to its very low thermal expansion during burn-out. This wax-filled photopolymer is a material for the production of full anatomical crowns and bridges with extreme dimensional accuracy in X, Y and Z, and exceptional surface finish. The burnout for parts 3D printed in Press-E-Cast is rapid, clean and ash-free, resulting in accurate, quality castings.

Specs

- Tensile Strength: 56 MPa

- Elongation at Break 3.5%

- Flexural Strength 115 MPa

- Flexural Modulus 3350 MPa

- HDT (Heat Deflection Temperature) / No heat treatment necessary: 150°C (284°F

Application

- Crown and bridge wax ups

- Pressing and casting full contour crowns

- Casting copings and subtractures

- Casting removable partial denture frameworks

Technology/Process

Continuous Digital Light Processing™ used with EnvisionTEC™ 3D printers.

E-Aqua Model

Eco-friendly material for orthodontic models

E-Aqua Model photopolymer is best-recommended for high-accuracy orthodontic models. This material allows an eco-friendly cleaning process by using just water, and no alcohol.

Full Description

A high green strength gives E-Aqua Model added strength and stability during the build, resulting in lower shrinkage and curling than similar products. The low viscosity of the liquid material allows for quick and easy cleanup of the models without the need to use alcohol.

Specs

- Tensile Strength: 55 MPa

- Elongation at Break: 5.5%

- Tensile Modulus: 2200 MPa

- Flexural Strength: 90 MPa

- Flexural Modulus: 2540 MPa

- Impact: 25 J/m

- HDT(Heat Deflection Temperature): 60.5°C at 1.82 MPa

- D Hardness 83

- Viscosity: 150 cP at 30°C

Application

- Crown and bridge models

- Orthodontic models

- Implant models

- Clear aligner models

- Diagnostic models

Technology/Process

- Continuous Digital Light Processing™ & Digital Light Processing technologies

E-Partial

Dental model making and clear aligner production

E-Partial is an accurate material for dental model making and clear aligner production. It maintains flexural strength to ensure clasp flex without breakage.

Full Description

E-Partial is a castable material developed to deliver delicate partial frameworks with thin features and some flexibility. Its stiffness allows for the production of a very hard retention grid and super-tight thin clasps to deliver a metal partial with the perfect fit every time.

Specs

- Tensile Strength: 57 MPa

- Elongation at Break: 3.6%

- Flexural Strength: 129 MPa

- Flexural Modulus: 3155 MPa

- HDT (Heat Deflection Temperature) – no heat treatment necessary: 130°C at 9,455 MPa, 78°C at 1.82 MPa

- Shore D 89

- Specific: Gravity 1.1 – 1.11 g/cm3

- Viscosity: 760 cP at 25°C

Application

- Crown and bridge models

- Orthodontic models

- Implant models

- Clear aligner models

- Diagnostic models

Technology/Process

- Continuous Digital Light Processing™ Technology on EnvisionTEC™ & Einstein 3D printers.

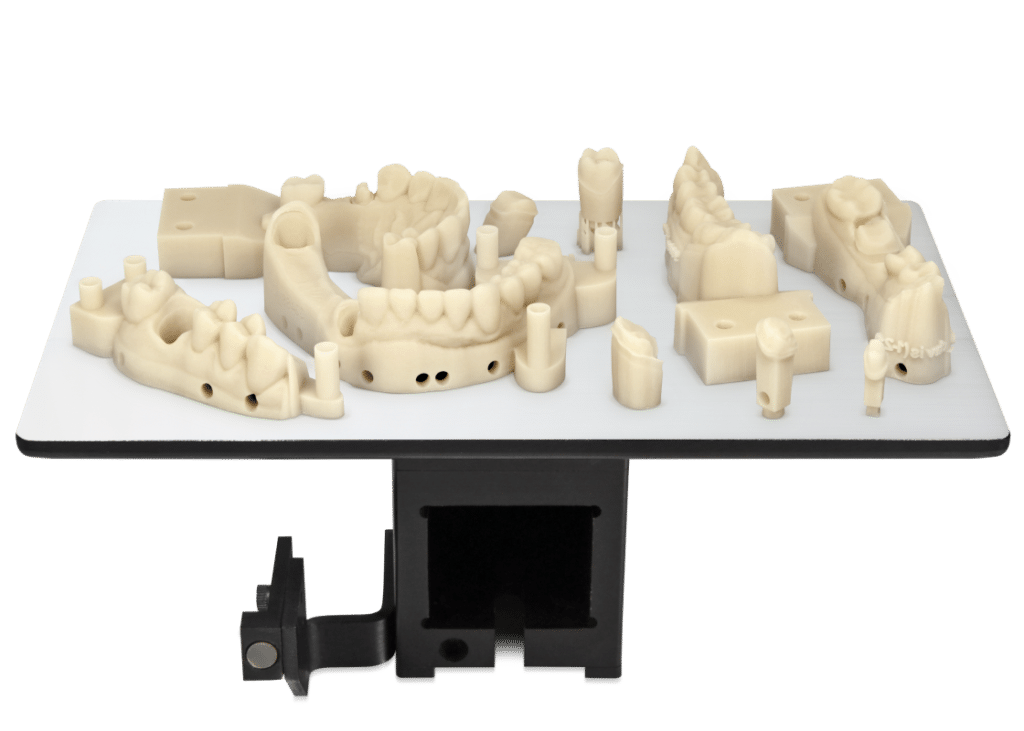

E-Model Light DLP

Material: E-Model Light DLP

E-Model Light DLP printing material is the perfect choice for a wide variety of high-accuracy dental modeling needs with exceptional surface needs.

Full Description

A high green strength gives E-Model added strength and stability during the build, resulting in lower shrinkage and curling than similar products. The low viscosity of the liquid material allows for quick and easy cleanup of the models.

Specs

- Tensile Strength: 55 MPa

- Elongation at Break: 5.5%

- Tensile Modulus: 2200 MPa

- Flexural Strength: 90 MPa

- Flexural Modulus: 2540 MPa

- Impact: 25 J/m

- HDT (Heat Deflection Temperature): 60.5°C at 1.82 MPa

- D Hardness 83

- Viscosity: 150 cP at 30°C

- Available colours: Natural, Light, Peach, Black, Beige

Application

- Crown and bridge models

- Orthodontic models

- Implant models

- Clear aligner models

- Diagnostic models

Technology/Process

Continuous Digital Light Processing™ used with EnvisionTEC™ 3D printers.

E-Model Beige

Material: E-Model Beige

E-Model Beige printing material for DLP and cDLM 3D printers is the perfect choice for orthodontic models for thermoforming aligners over.

Full Description

A high green strength gives E-Model Beige added strength and stability during the build, resulting in lower shrinkage and curling than similar products. The low viscosity of the liquid material allows for quick and easy cleanup of the models.

Specs

- Tensile Strength: 55 MPa

- Elongation at Break: 5.5%

- Tensile Modulus: 2200 MPa

- Flexural Strength: 90 MPa

- Flexural Modulus: 2540 MPa

- Impact: 25 J/m

- HDT(Heat Deflection Temperature): 60.5°C at 1.82 MPa

- D Hardness 83

- Viscosity: 150 cP at 30°C

Application

- Crown and bridge models

- Orthodontic models

- Implant models

- Clear aligner models

- Diagnostic models

Technology/Process

Continuous Digital Light Processing™ & Digital Light Processing used with EnvisionTEC™ 3D printers.

E-Denstone

Material: E-Denstone

E-Denstone is a resin for the rapid production of highly accurate, scannable dental models.

Full Description

With a look and feel similar to traditional gypsum models, E-Denstone delivers a matte finish, which assists in accurate scanning for verification purposes. This material allows the user to die trim, margin mark with a red pencil and hand wax to the die without concern over layer lines. Die paint sticks to the dies just like plaster and won’t peel off.

Specs

- Tensile Strength: 56 MPa

- Elongation at Break: 3.5%

- Flexural Strength: 115 MPa

- Flexural Modulus: 3350 MPa

- HDT (Heat Deflection Temperature), No heat treatment necessary: 140°C (284°F)

Application

- Crown and bridges models

- Mounting casts

- Counter models

- Casting partials

- Denture repairs

Technology/Process

Continuous Digital Light Processing™ & Digital Light Processing used with EnvisionTEC™ 3D printers.

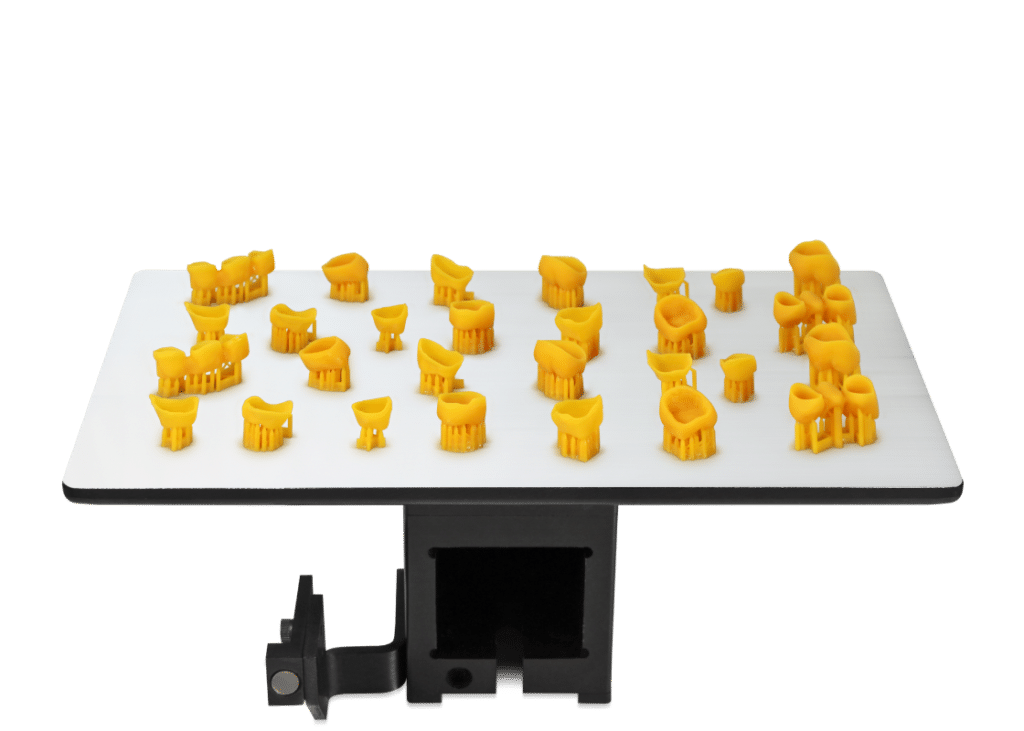

E-Tray

Material: E-Tray

E-Tray is a 3D printing material for use in producing individual customized impression trays.

Full Description

Dental impressions can be used for preliminary impressions, final impressions, and bite registrations, and are used for prosthodontics, orthodontics, dental crown and bridges, maxillofacial prosthetics, oral and maxillofacial surgery, in diagnosis, mouth guards, whitening trays, and for the permanent dental record to document before and after phases.

Specs

- Physical State: Liquid

- Colour: Blue

- Density: 1.1 g/cm3

- Viscosity: 700-1200 Pas

Application

- Custom impression trays

Technology/Process

Continuous Digital Light Processing™ used with EnvisionTEC™ 3D printers.

Machine Properties

Build Envelope |

Build Envelope180 x 101 x 175 mm (7.09 x 3.98 x 6.89 in.) |

Build Speed |

Build SpeedUp to 45 mm/hour, material dependent |

Native XY Resolution |

Native XY Resolution93 microns |

XY Resolution with Contour Gray Scaling |

XY Resolution with Contour Gray Scaling60 microns |

Dynamic Z Resolution |

Dynamic Z Resolution50 µm to 150 µm, material dependent |

Data Handling |

Data HandlingSTL files |

Footprint (L x W x H) |

Footprint (L x W x H)15.4 x 16.93 x 25.02 in. (39.1 x 43 x 63.6 cm) |

Weight |

Weight70 lbs (32 kg) |

Electrical Requirements |

Electrical Requirements110/220 VAC 50/60 HZ 5A |