2oneLab® 2CREATE

2oneLab

2CREATE

The future of dental prostheses production

The 2CREATE is a game-changer for dental labs, offering a lower cost and higher productivity metal 3D printing option for producing dental prostheses. With an open-material system architecture and a high-powered 250W fiber laser, you can process CoCr and Titanium powders from the supplier of your choice further optimizing operational costs and ensuring flexibility.

Simplify Your Metal Digital Workflows

With the 2CREATE metal 3D printer, you can redefine the way your lab produces metal applications. Powered by 250 W CW fiber laser and laser powder bed fusion technology, this 3D printer can process demanding alloys at high printing speeds while maintaining quality and durability. You’ll be able to manufacture higher-quality 3D-printed dental applications in less time compared with conventional processes.

Key Features

System Highlights & Performance

Efficiency and Power in a Compact Size

2CREATE is compact, requiring less floor space than other metal 3D printing systems on the market. Its 110 mm x 100 mm build volume ensures parts can be printed quickly and precisely, enabling your lab to maximize throughput.

FDA and Health Canada Approved Materials

With an open-material system architecture, the 2CREATE can process common dental alloys with the potential to scale to even more applications in the future.

| Cobalt-based alloy

CoCr |

Titanium

Ti64IV |

Part Properties

- Maximum Part Size:

- 100 x 100 mm

- Typical Layer Thickness:

- 20 µm – 40 µm (adjustable)

- Materials:

- Steel, Cobalt Chrome, Titanium, Aluminium, Inconel

Hybrid Workflow

Step 1

3D Printing and De-Powdering

Once the printer has completed the printing process, the component must be depowdered. To do this, the powder surrounding the component is removed from the build envelope. This can be done manually or with the aid of a vacuum cleaner which can then be separated with 2Clean powder recycling system for future use.

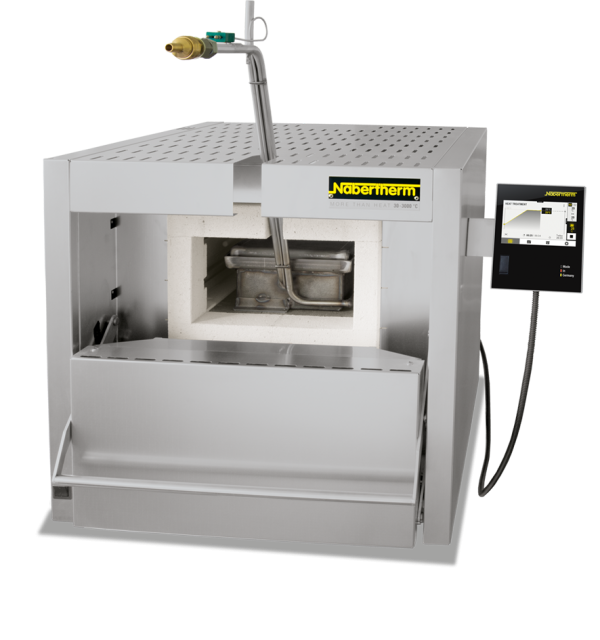

Step 2

Heat Treatment

During the printing process, internal stresses occur due to the high-temperature gradient in the material. Through annealing the part with high heat you are able to relieve stresses and prevent part deformation.

Step 3

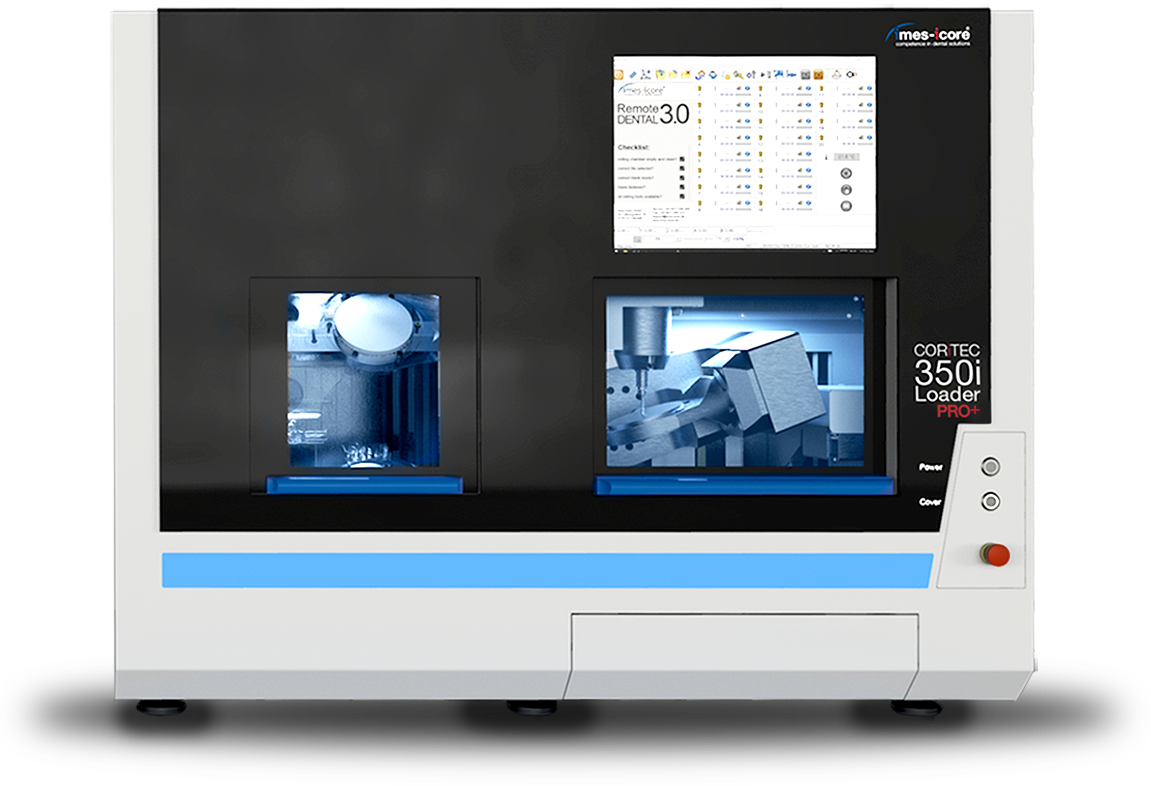

Milling / Machining

In order to automate the process, parts 3D printed with the 2CREATE can go through a hybrid milling process to achieve improved accuracy and surface finish as well as create the right abutment interfaces.

Step 4

Surface treatment

The final step in the process ensures the highest quality fit and finish for the end patient. Through the DLyte dry-electropolishing process you can create a mirror finish on your metal components without the need for arduous and labor-intensive hand polishing.

2BUILD

Innovative software to simplify the dental metal 3D printing workflow

The 2BUILD software is developed for smart automation and optimization of your 3D printing results.

It’s extremely user-friendly thanks to features like:

|

|

- Its print files are in a transparent G-code format, making the 3D printing process straightforward.

User Interface

Easily monitor the build process and operating conditions at a glance with the

2CREATE user-friendly interface

2CREATE Advantages

Easy connection to start the 3D printing process

The 2CREATE has a very compact design. Thanks to its air-cooled fiber laser, a 230V connection (1 phase) is sufficient. You’ll only need the inert gas to operate the system. For CoCr (Cobalt Chrome), you need Nitrogen; for the Titanium, you’ll need Argon.

Rapid 3D printing

In the case of components such as crowns or partials and the selected powder, the 3D printing time on the 2OneLab system’s fully loaded build plate of 100 mm diameter is approx. 5 hours.

Open system

CoCr (Cobalt Chrome) and Titanium are among the typical materials used in the dental sector. Thanks to the open system architecture of the 2CREATE 3D printer, there are no restrictions regarding the material used. Its software helps you to quickly create new printing parameters for new materials.

Large build platform

Depending on the shape of your dental indication, you can 3D print up to 100 crowns on the 2CREATE’s build plate.

Technical Specifications

2CREATE Metal Printer

Process |

ProcessPowder Bed Fusion |

Machine Size |

Machine Size720 x 860 x 1790 mm, 450 kg |

Build Envelope Size |

Build Envelope Size110 x 110 mm |

Reservoir Volume |

Reservoir Volume110 x 200 mm |

Laser Source |

Laser SourceFiber Laser 250 W |

Precision Optics |

Precision OpticsF-Theta Lens |

Power Supply |

Power Supply230 V / 1 – 50 / 60 Hz |

Inert Gas |

Inert GasNitrogen, Argon |