DLyte Desktop Dental

GPAINNOVA

DLyte Desktop Dental

Accessible and affordable metal surface finishing

The DLyte Dental system is a compact metal surface finishing machine powered by DLyte dry electropolishing technology. Small to medium-sized dental and orthodontic labs can now smooth and polish dental appliances like removable partial dentures, bars, and crowns, in-house with an automated workflow. From grinding to smoothing to mirror finishing, the DLyte Desktop Dental system will simplify your metal post-processing and leave you with stunning metal devices.

Dry Electropolishing

in a Compact Footprint

Suitable for cobalt-chrome (CoCr), titanium (Ti) and stainless steel

Powered by groundbreaking dry electropolishing technology, the DLyte Desktop Dental and Desktop Pro systems enable the metal surface finishing of any cast, sintered, or milled metal part whether they’re cobalt chrome, titanium, or stainless steel. With a wide range of compatible materials, an easy-to-use platform, and an affordable price point, the DLyte desktop systems make high-quality automated metal surface finishing accessible to dental labs of any size.

Two Systems

Designed for Flexibility

DLyte Desktop Dental

DLyte Desktop Dental is the compact version for the treatment of cobalt chrome.

DLyte Desktop Pro

DLyte Desktop Pro is suited for the treatment of titanium and stainless steel.

Key features

Applications

Fixed Prosthesis

|

|

|

|

Implant Prosthesis

|

|

|

|

Removable Prosthesis

|

|

Cobalt Chrome | Casting |

Advantages

Plug and Play

At the press of a button, technicians can now begin surface finishing metal parts from the comfort of their desktop. With no prior training, DLyte Desktop Dental machines maneuvering is as easy as a walk in the park.

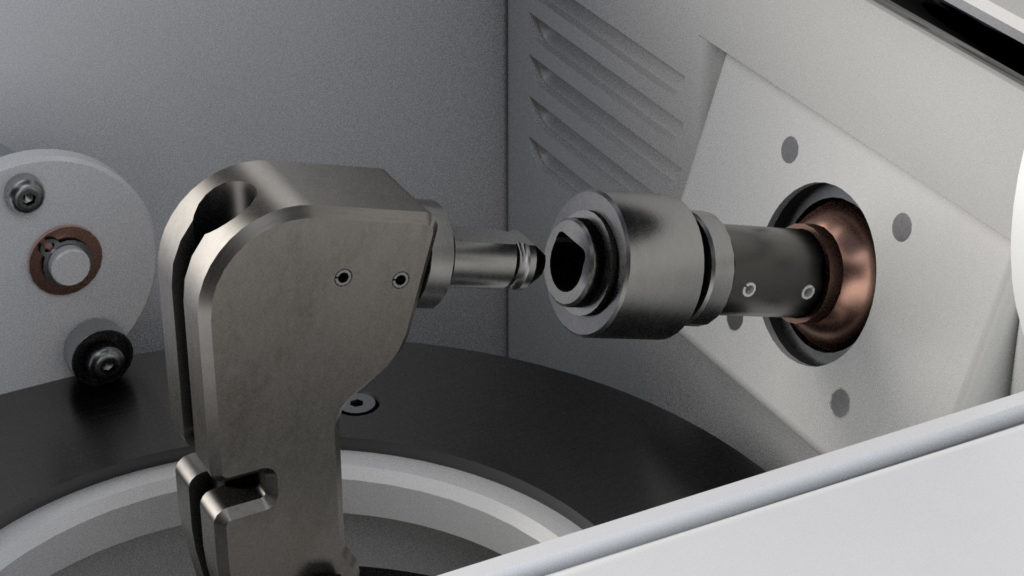

Quick Coupling and Releasing of the Holder

You can reduce the loading and unloading times thanks to the convenient holder fixation system with easy pressure and automatic locking system.

Ultra-Compact and Silent

No matter how limited your space is, you can have access to the latest surface metal finishing technology with the DLyte Desktop. It is extremely space-saving as it can be operated on top of a 450 mm x 521 mm table. Besides its compact size yet high performance, the machine’s operation is smooth and silent.

Easy Electrolyte Handling and Storage

The DLyte Desktop equipment uses solid electrolytes which ensures a clean, quick and safe media loading and unloading. This is an essential advantage as it is highly recommended for the media to be removed from the machine and be stored in order to preserve optimum performance.

DLyte HUB

Connectivity is everything and DLyte Desktop is no different. It comes with Ethernet and USB ports offering connectivity to the new client’s portal in the cloud “HUB DLyte“.

HUB DLyte is a unique access point where you can activate electrolytes and download user and maintenance manuals, product technical datasheets, and process parameters for your DLyte machines. This access to the consumables activation is efficient and secure. In addition, the new cloud platform allows you to be informed about your polishing processes, electrolyte status and so much more.

How it Works

DLyte Desktop systems work by combining the electrical flow created by the high-precision rectifier with the movement of the pieces through the electropolishing media. This results in ion exchange, removing material only from the peaks of roughness. The process does not round edges and can access internal corners that are not easily accessed mechanically.

Step 1

The parts are clamped onto the holder.

Step 2

The holder is coupled.

Step 3

The program is selected.

Step 4

Surface finishing treatment takes place.

Before DLyte surface finishing

After DLyte surface finishing

Technical Specs

Desktop Dental

|

Desktop PRO

|

|

MATERIALS |

||

Cobalt Chrome |

✔ | ✔ |

Stainless Steel |

✖ | ✔ |

Titanium |

✖ | ✔ |

INITIAL KIT |

||

Holder Finger |

✔ | ✔ |

Holder Bars with Analogs |

Not included | ✔ |

Holder Spring |

Not included | Not included |