MillBox

MILLBOX™

CIMsystem®

The Smartest Dental CAM system

MillBox offers a cutting-edge dental CAM solution, catering to all your restoration needs, regardless of the material used.

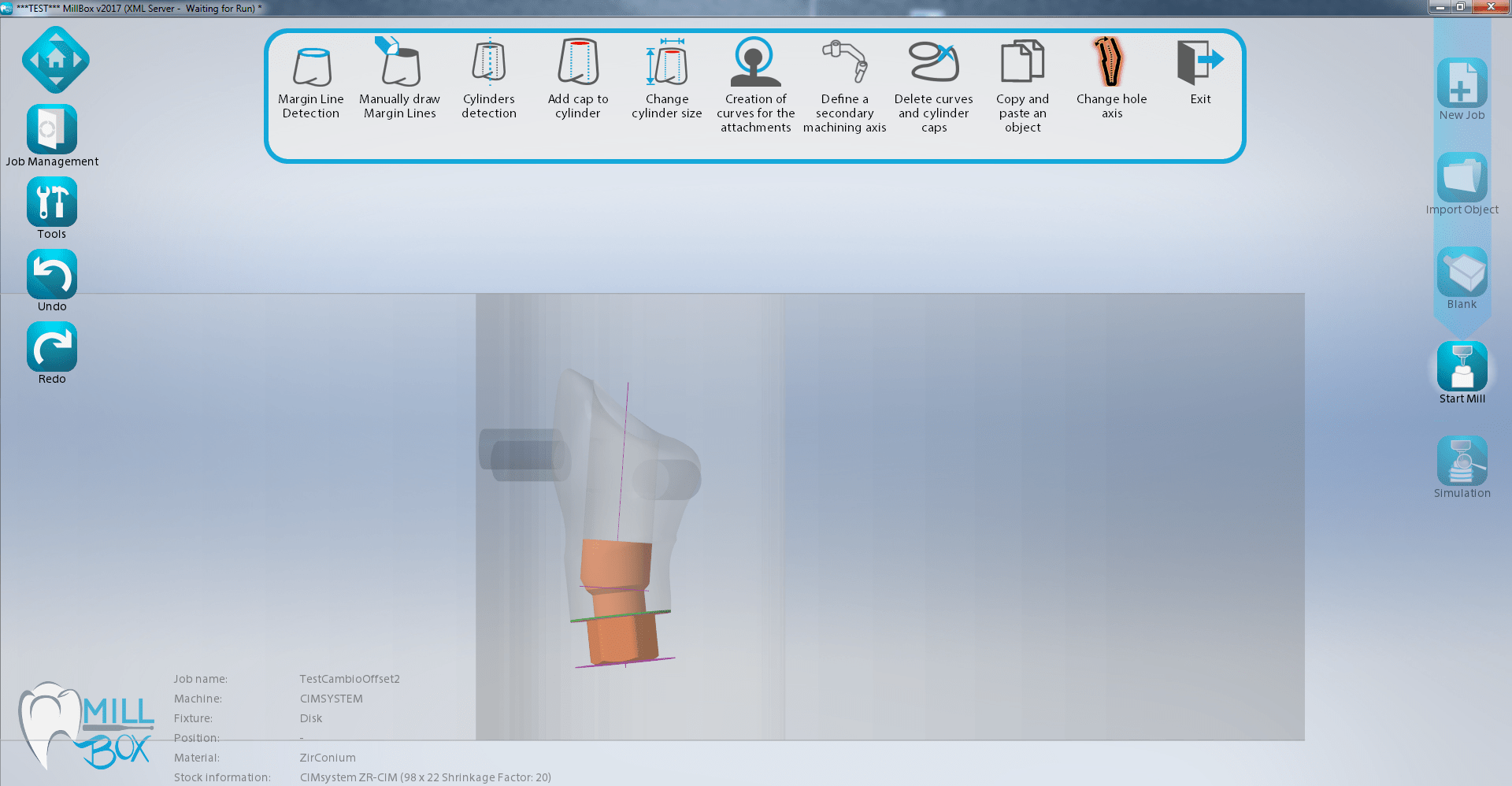

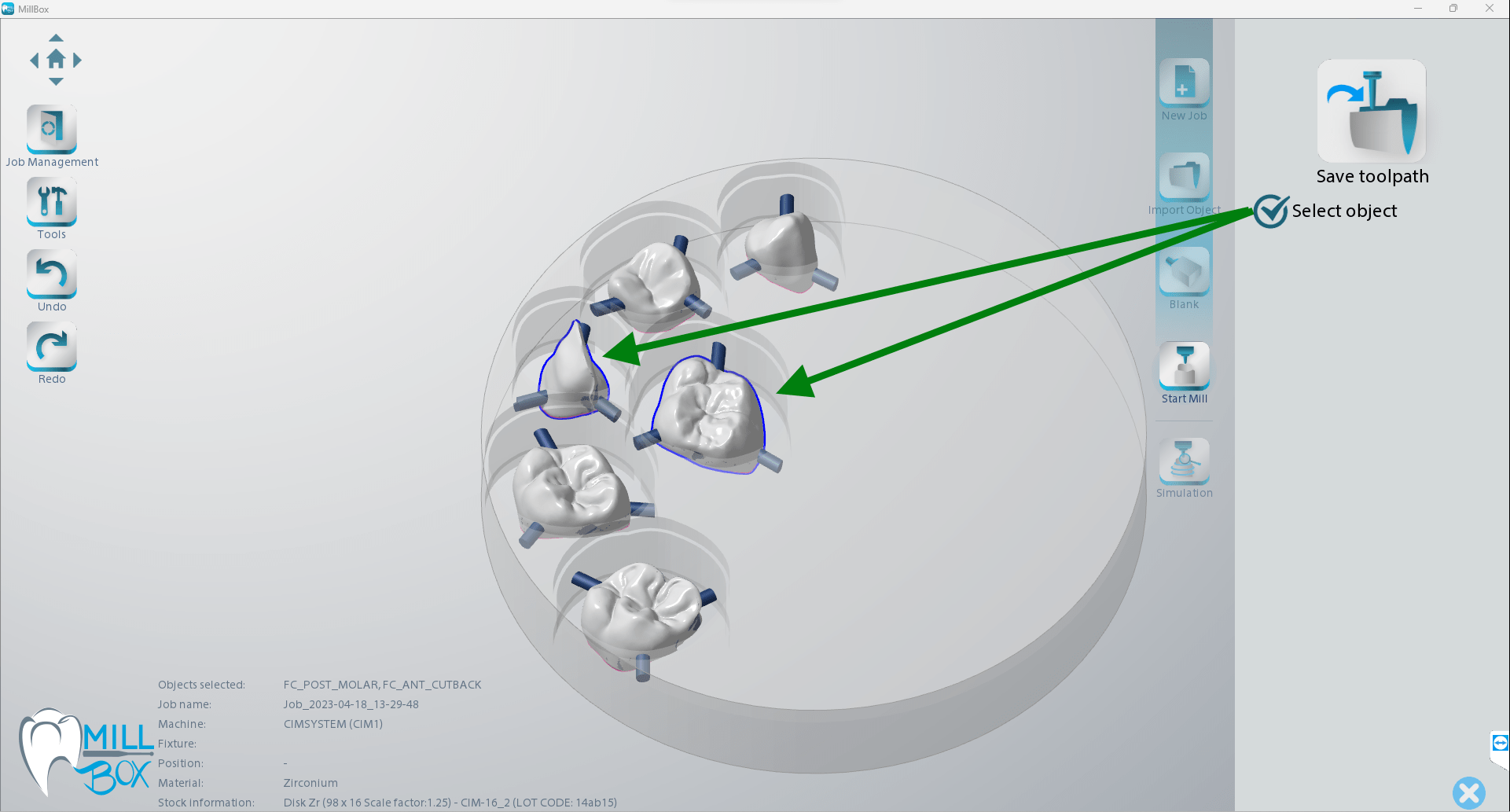

Featuring an intuitive and visually appealing user interface, MillBox streamlines the nesting and toolpath creation process, making it accessible to both beginners and experienced professionals. Its interface is purpose-built for immediate use, with exciting new functionalities to enhance workflow efficiency.

Tailored to meet the demands of dental lab technicians, clinicians, milling centers, and mill makers, MillBox ensures high-performance results in less time, to simplify your work into a few straightforward steps.

Features

Benefits

State of the art

Dental Manufacturing

- A.I. makes dental CAM more intuitive

- Automatic recognition of different types of implant-abutment connections (Internal vs. External)

- Automatically separates the surfaces that make up the implant connection from its customized part.

- A.I. enhances dental CAM safety

- It automatically detects the area of the emergency contour with the possibility of selecting the part using a unique feature and carrying out finishing operations designed to obtain an optimal result for this critical area in implant work.

- A.I. makes dental CAM more careful

- Automatically selects the most used blank based on the areas already used and the number of elements to be milled with the automatic positioning of the objects.

- A.I. makes dental CAM more flexible

- It allows you to use residues from other CAM software as well. Importing a photo enables the recognition of already used areas, and the contours are automatically reconstructed and stored as already used areas in the new blank.

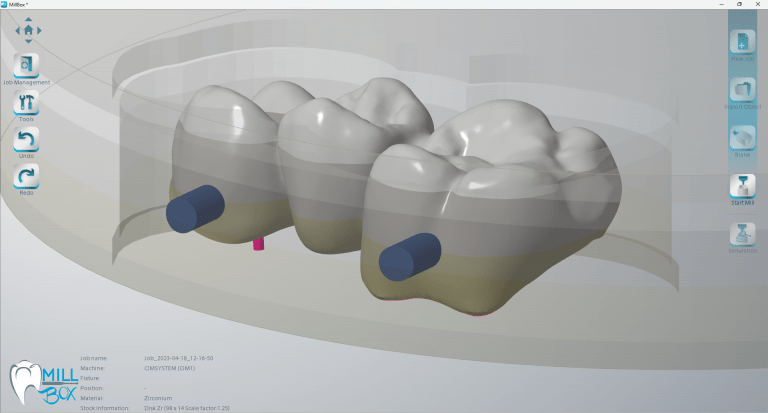

MillBox is a premier dental CAM Suite that is capable of driving any milling machine with a single interface. MillBox can mill any kind of restoration in any material and is equipped with a simple, yet powerful & easy-to-use interface that simplifies the nesting process for your cases.

It is highly customizable & fully featured to support standard and ad-hoc milling strategies according to your mill’s specific capabilities. MillBox uses predetermined libraries while affording you the flexibility of building your own strategy. MillBox also offers synergistic manufacturing workflows featuring both additive and subtractive technologies with the Make&Mill add-on.

MillBox is designed for dental lab technicians, clinicians, milling centers, mill makers and any user seeking a CAM (Computer Aided Manufacturing) that is constantly innovating and improving. This software also boasts specialized features for high production environments leveraging Artificial Intelligence and production automations.

Versions & Technical Features

MillBox Standard | Built with all the tools you need to get started in CAM |

MillBox Expert | Recommended for: Milling Centres, Mid-High Volume Production & Power Users |

|

Access to All Restorations |

☑ | ☑ |

Smart Support Pins

|

☑ | ☑ |

Priority-Based Milling | Prioritize your cases based on urgency. |

☑ | ☑ |

Designate Support Pins in Pre-Production | Designate support pins to simplify nesting with the free LAB3DExplorer utility. |

☑ | ☑ |

Multi-Project Toolpath Calculation | Easily group milling jobs in batches that can be calculated together |

☑ | ☑ |

Easy Upload and Navigation of STL Files | Multi-import files and filter through cases quickly and easily |

☑ | ☑ |

Intelligent Stock Management | Make smart use of partially used stock |

☑ | ☑ |

Multi-Shaded Material Visualization |

☑ | ☑ |

Material Barcode Scanning & Printing |

☑ | ☑ |

Complete Machining Simulation |

☑ | ☑ |

Mobile Notifications & Notification Sounds |

☑ | ☑ |

Machine Webcam Live View |

☑ | ☑ |

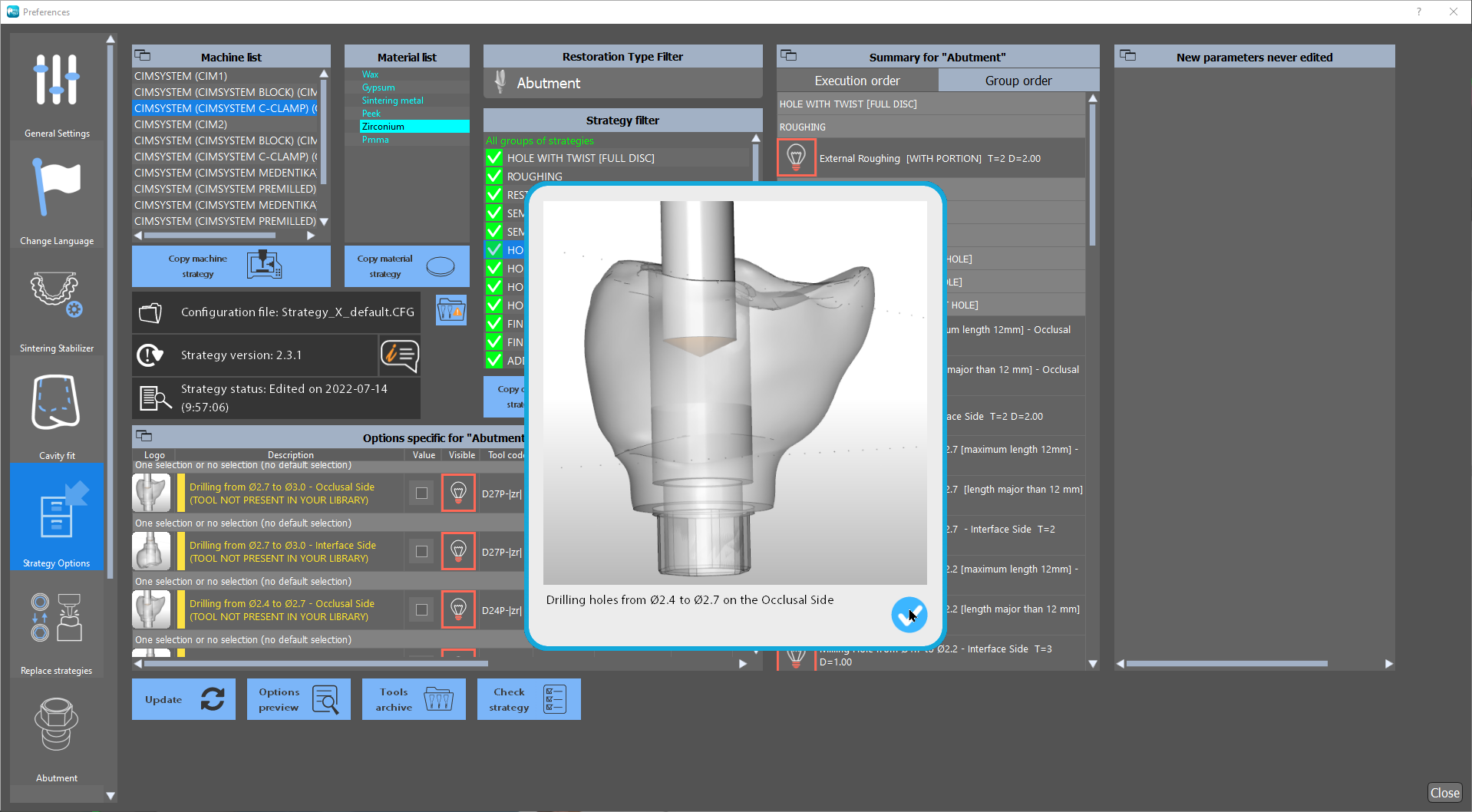

Strategy Editor Access | Easily adjust milling routines to suit your tooling or consumables |

☒ | ☑ |

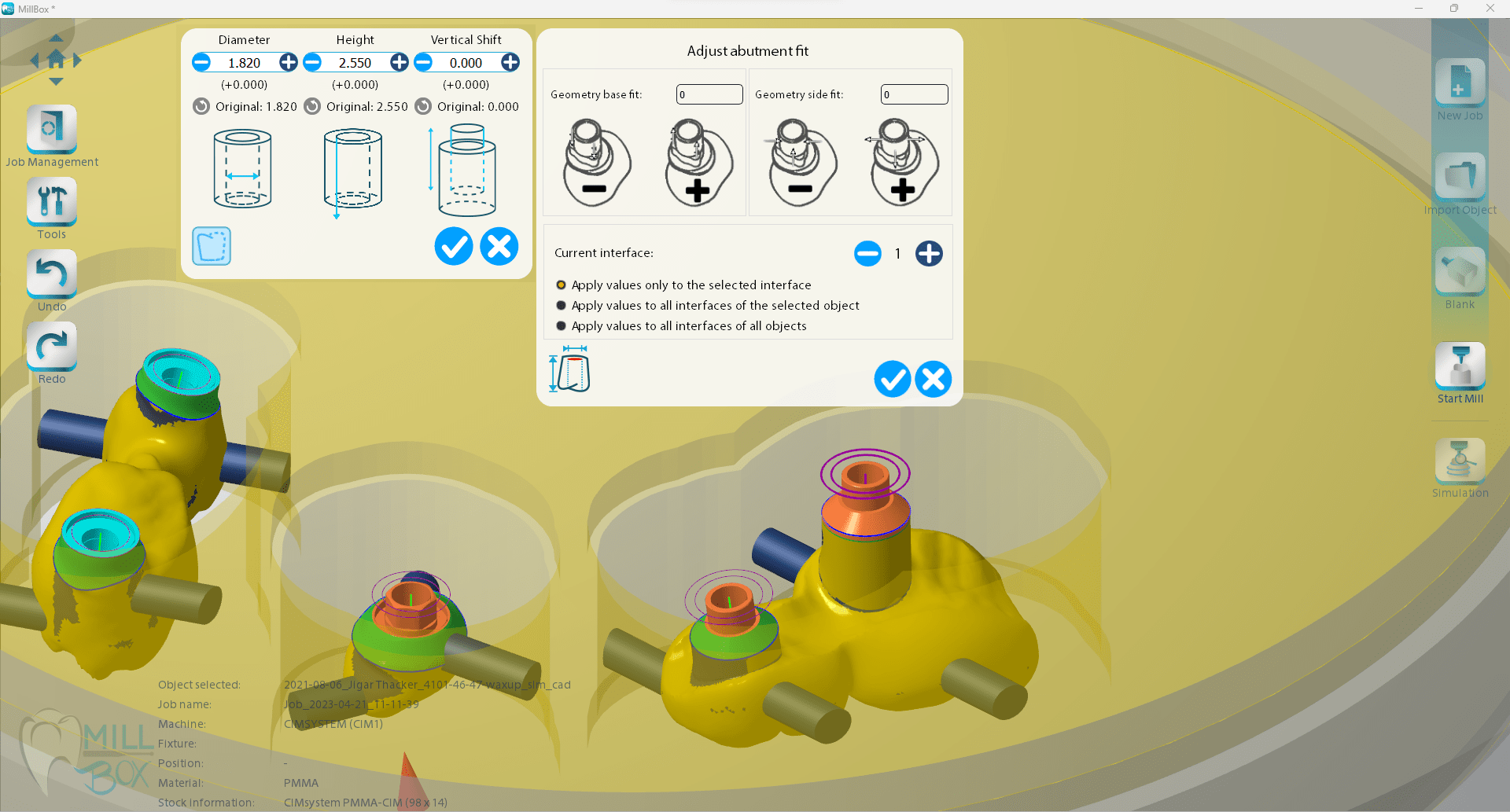

Implant Abutment Fine Tuning & Adjustments | QA is paramount when milling Implant Abutment cases. MillBox helps you to fine tune machining to produce consistent results, every time. |

☒ | ☑ |

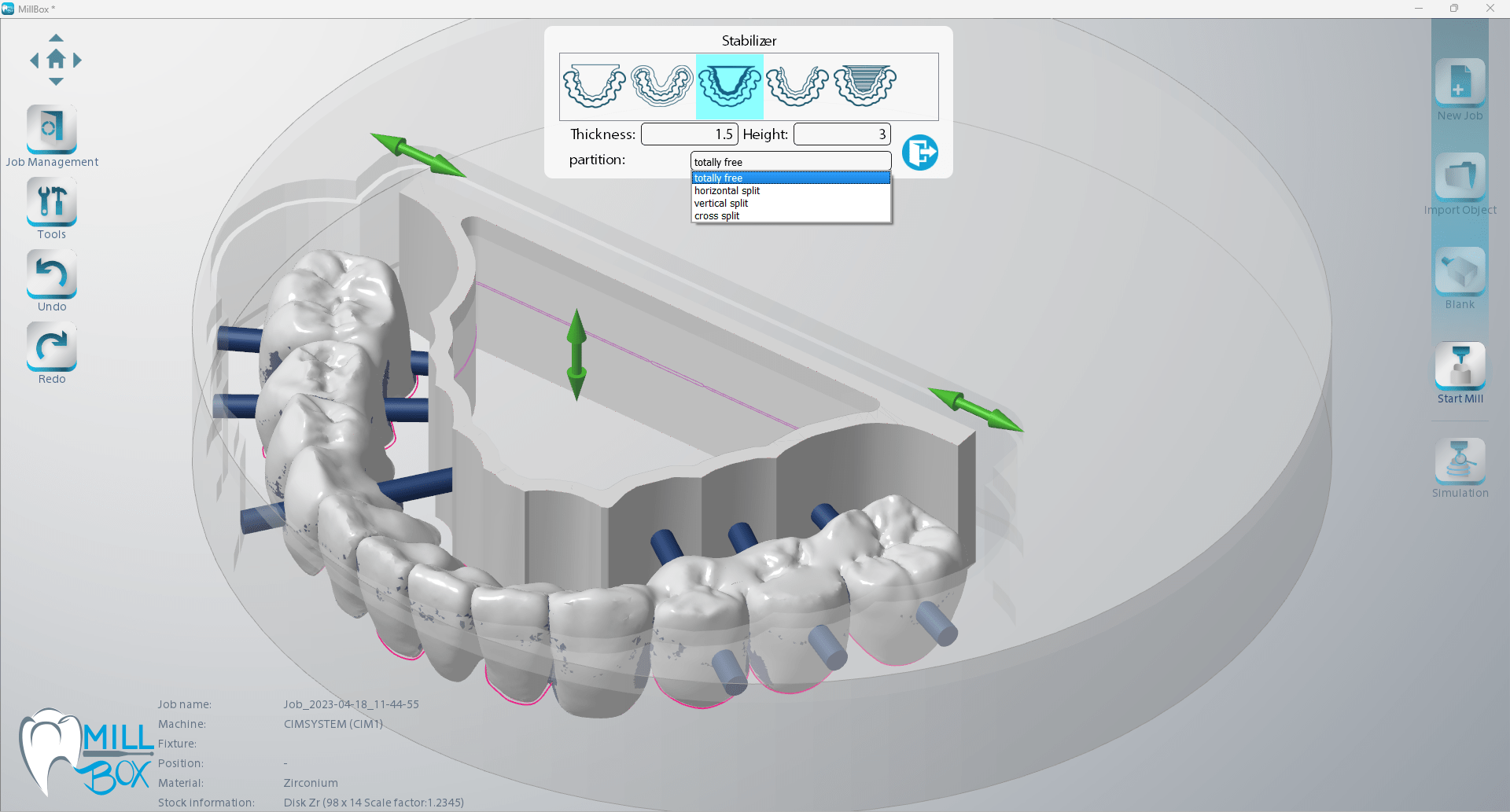

Customizable Sintering Stabilizers |

☒ | ☑ |

Copy & Paste Parts |

☒ | ☑ |

Access to SUM3D |

☒ | ☑ |

Optional Modules

You can acquire optional modules individually and integrate them into the standard Millbox setup for enhanced customization. See below a brief overview of some of the essential inclusions within the Comfort and Advanced packages.

The Advanced Module includes all functions, part of the Comfort Module, plus some extra.

COMFORT

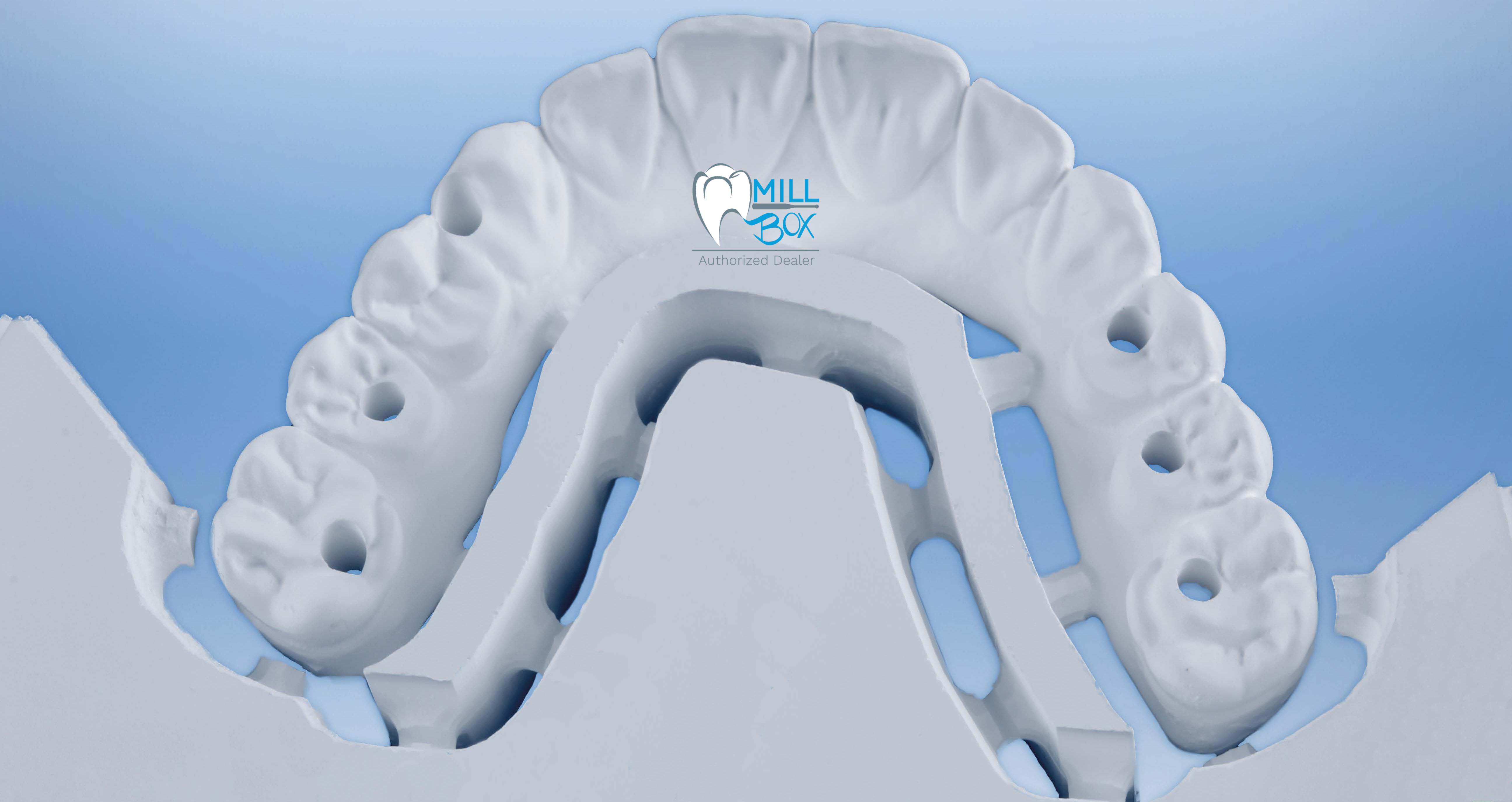

Creating Sintering Stabilizers on your parts during nesting can prevent the warping of parts and is crucial to maintaining uniform shrinkage during the sintering process. MillBox allows you to choose between 6 different types of standard bridge stabilizers. Each stabilizer has its own structure that adapts to the kind of object requiring support. Some stabilizers are material-specific.

MillBox also supports the use of custom-designed stabilizers if desired.

This feature allows you to select, define, and visualize a multi-shaded blank.

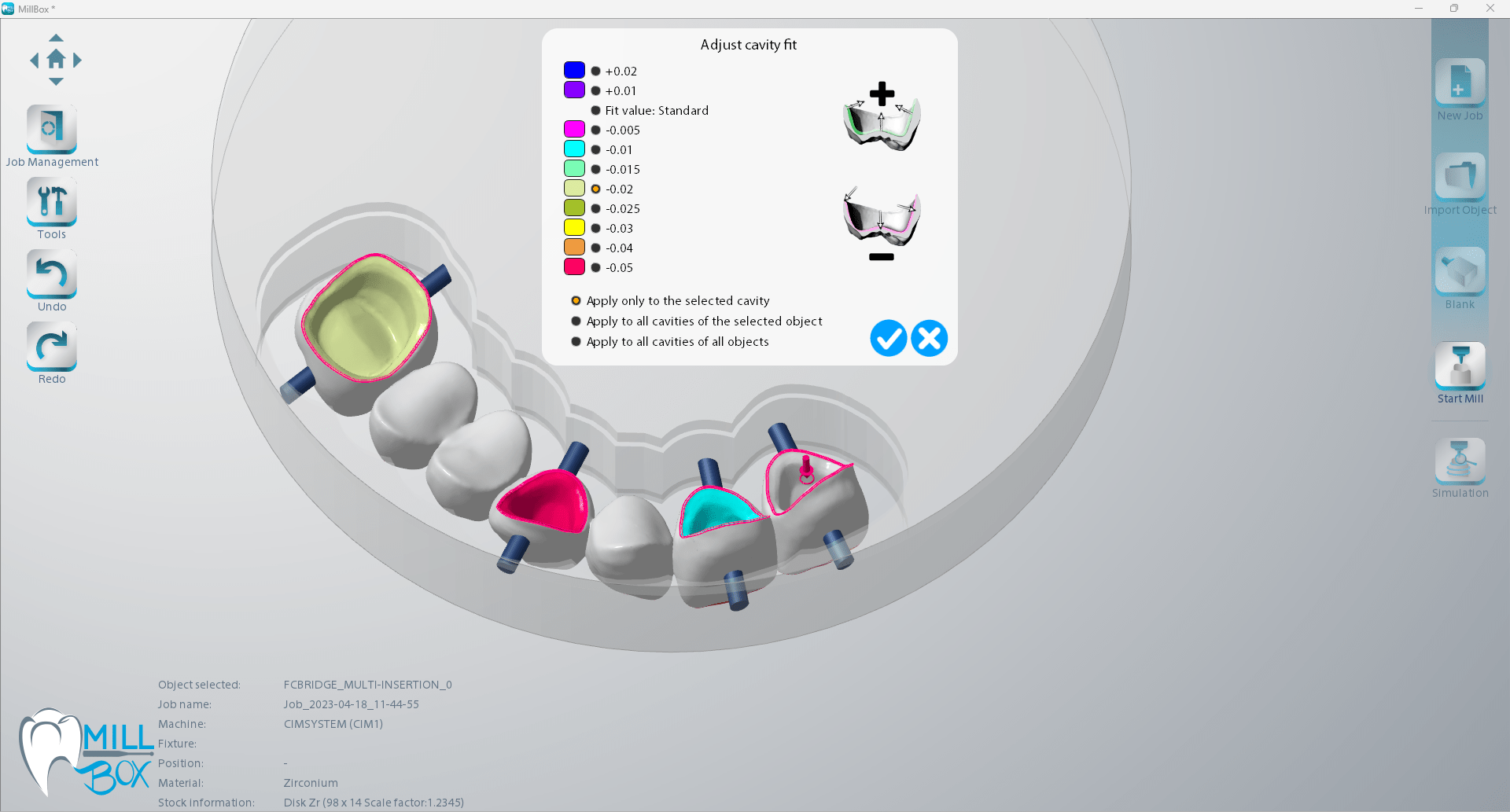

If the fit of a milled restoration is too tight or loose, you can make adjustments within the CAM that affect how much material is left behind or how much additional material will be cut away. These changes should be performed in the CAD, but can now be executed during nesting, saving you the time to redesign a case.

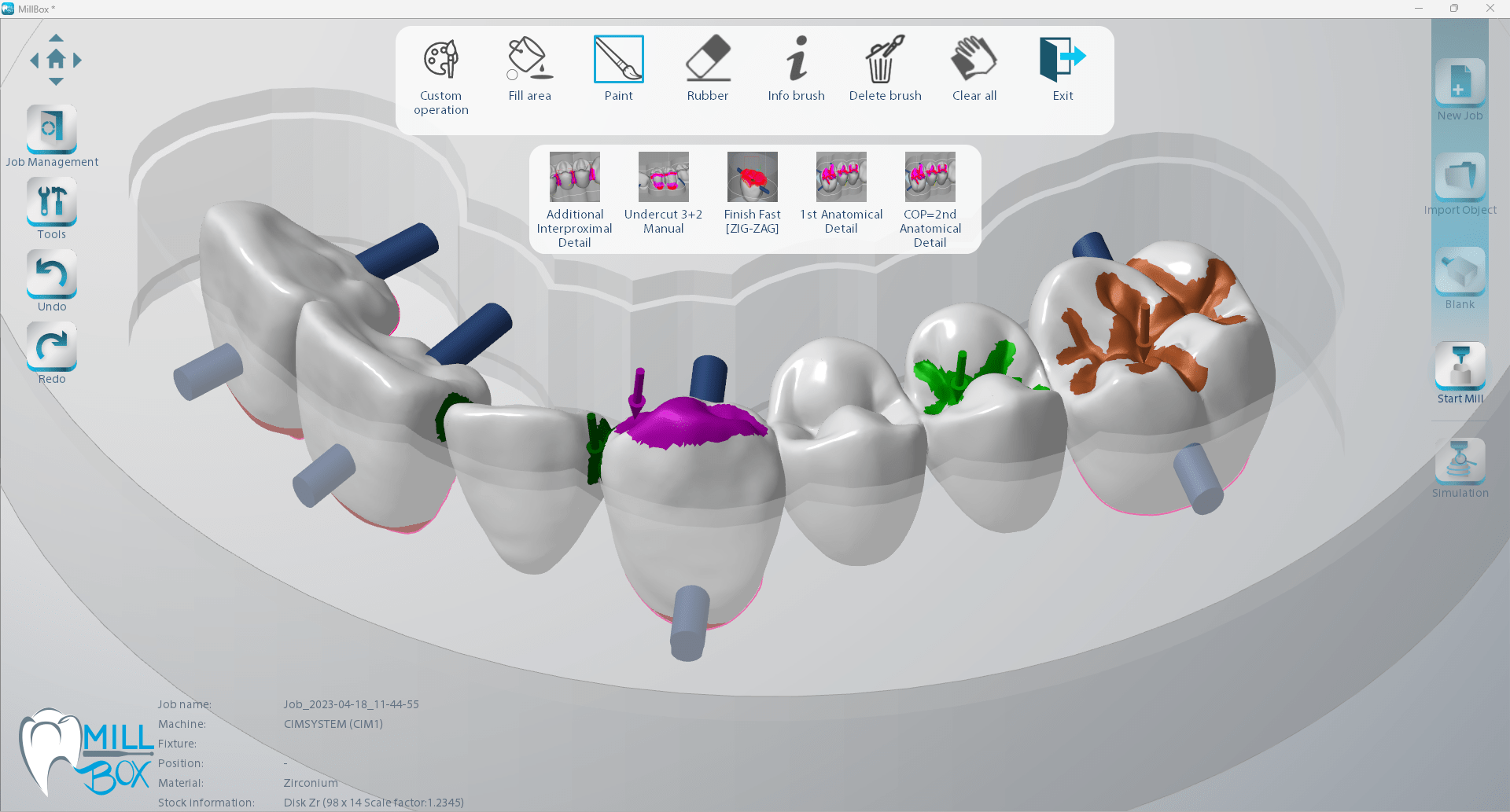

With targeted machining, you can define special or unique features on a part that requires additional detail or finishing. Using the brush tool, you can virtually paint areas that may require a different level of finishing. This feature can be applied through one of several categories of special finishing – new categories are added as needed.

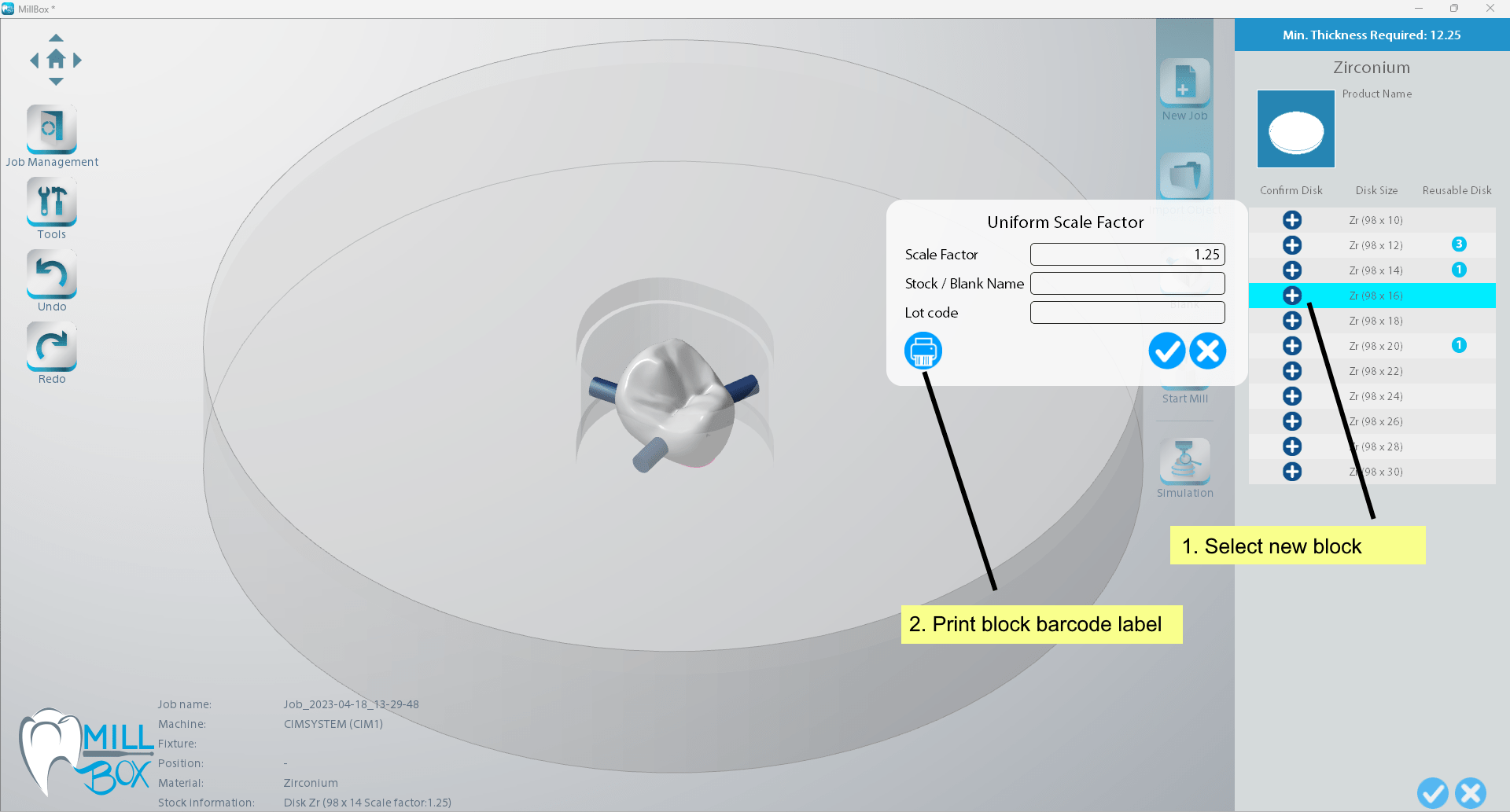

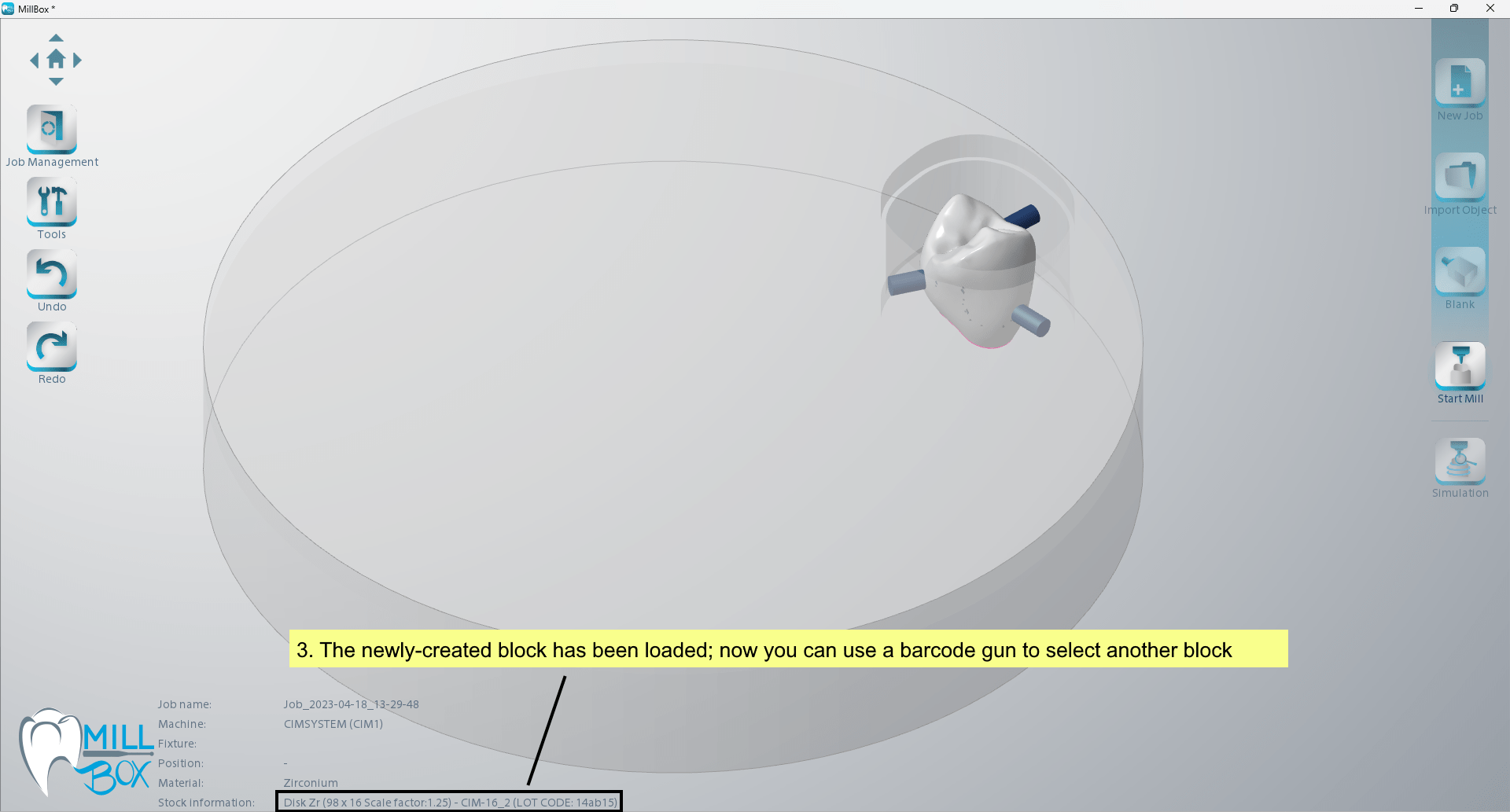

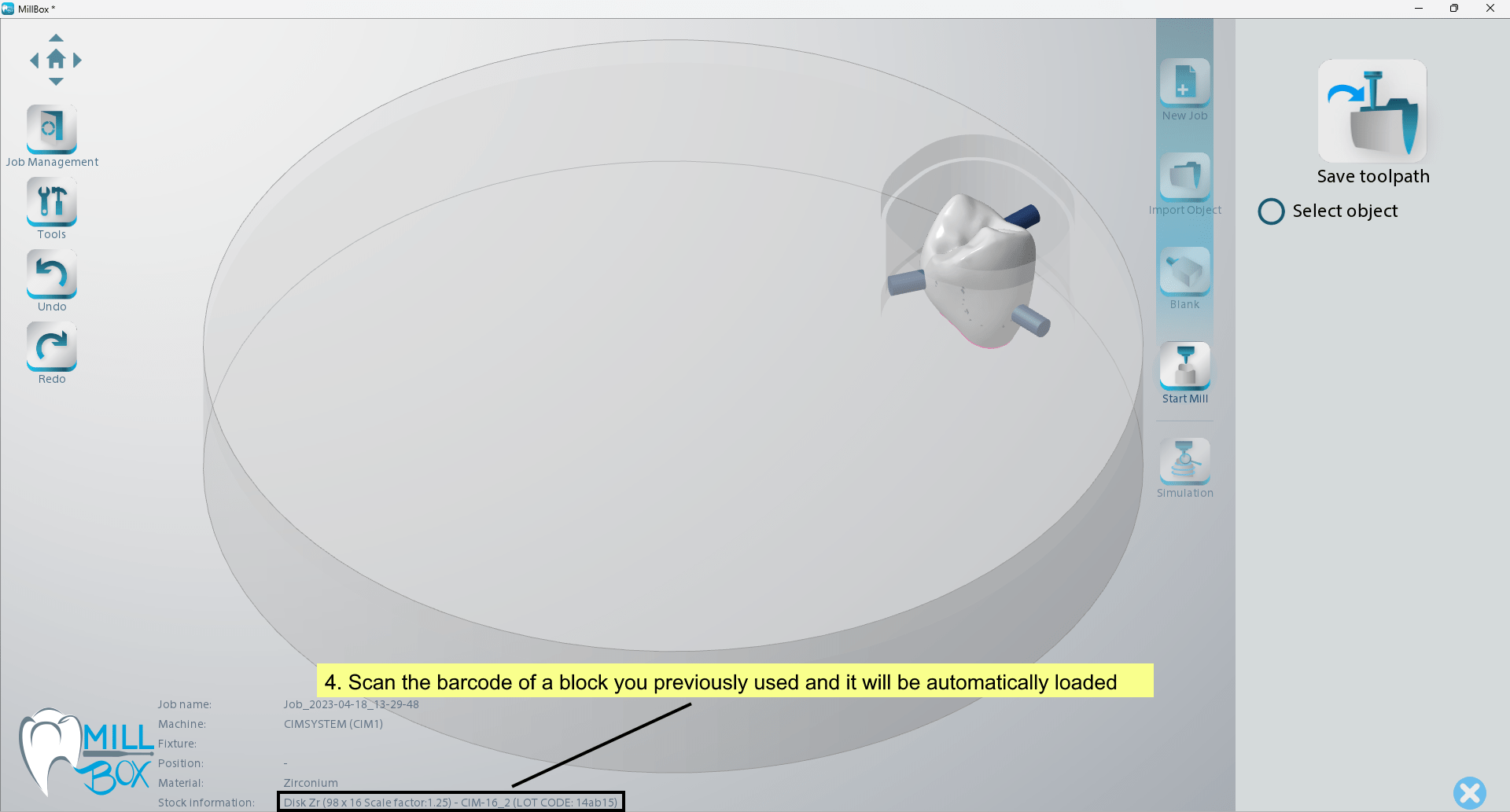

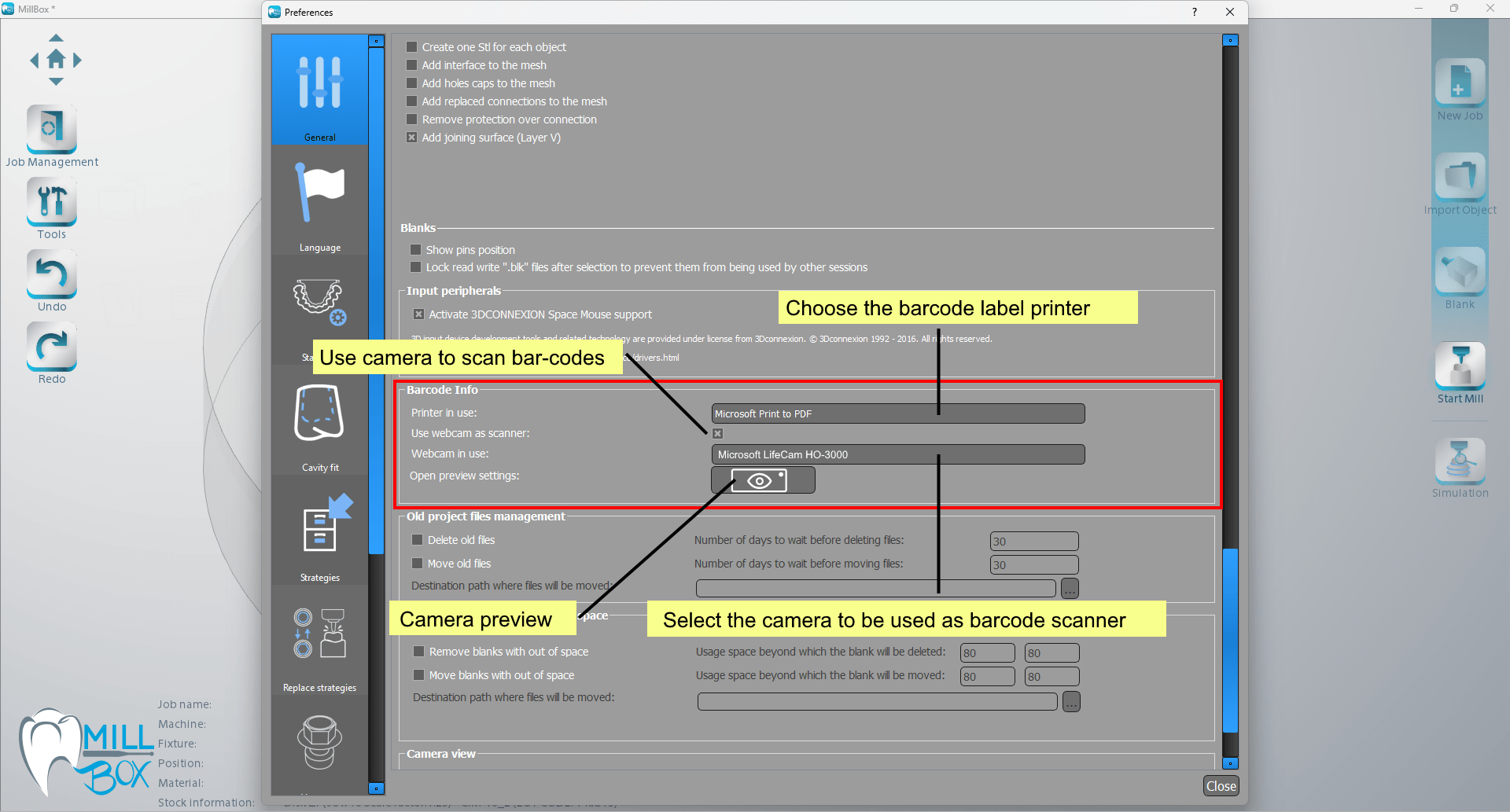

With this feature, MillBox can associate a unique code for every new blank the user creates. Upon blank creation, you can print a unique barcode label specific to the material and affix it directly to the side of the blank. As you progress through the workflow, you can scan the barcode label (using a webcam or barcode scanner). When the code is scanned, MillBox will automatically import the corresponding blank as long as it is presented in the partially used stock library.

|

|

|

|

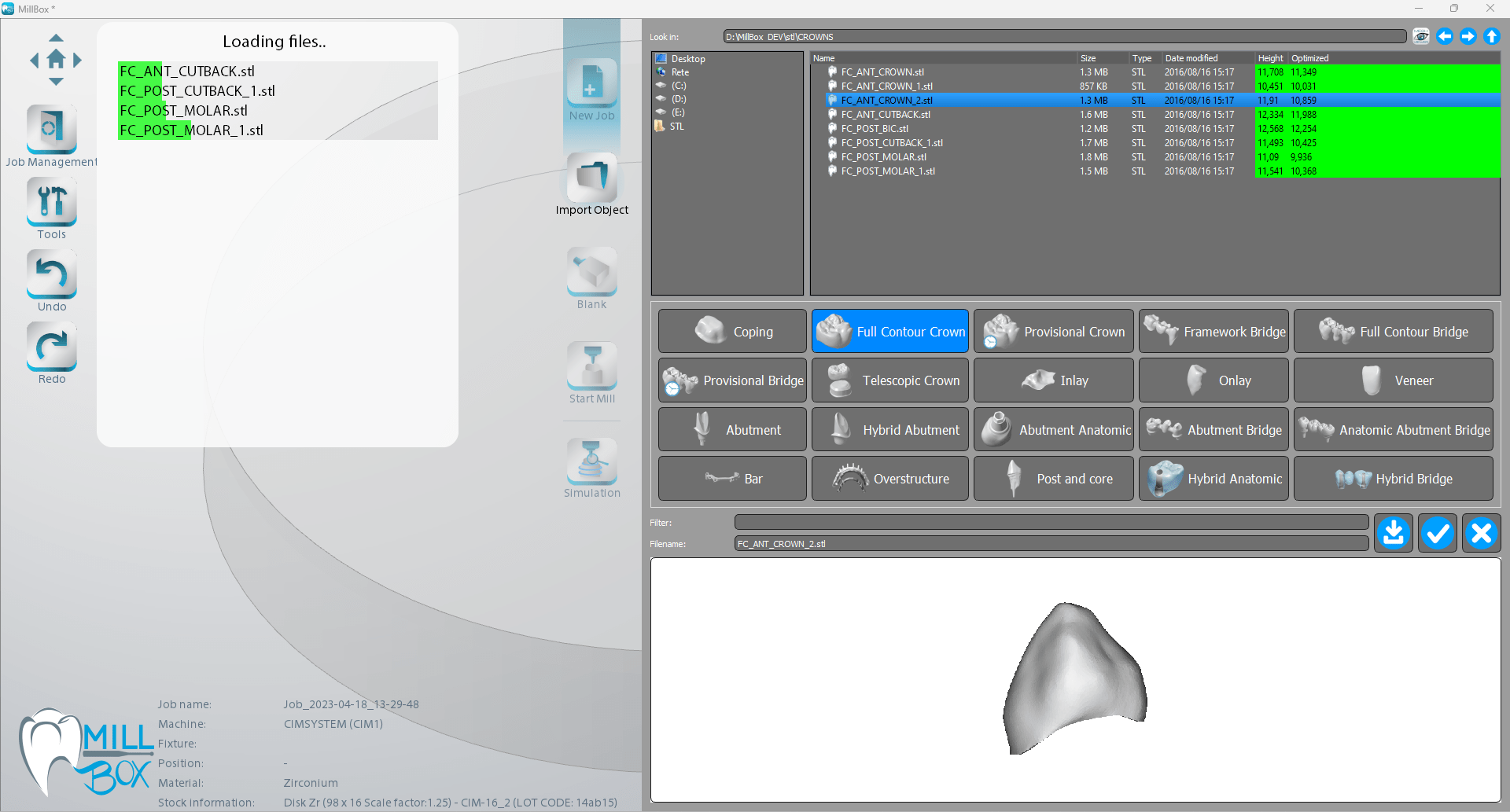

MillBox can import up to 14 files at the same time. This can save a lot of chair time spent nesting. While files are being loaded in the background, MillBox’s interface remains unlocked so you can select additional files for import – even if they are different object types. This results in up to 80% faster loading times when importing files.

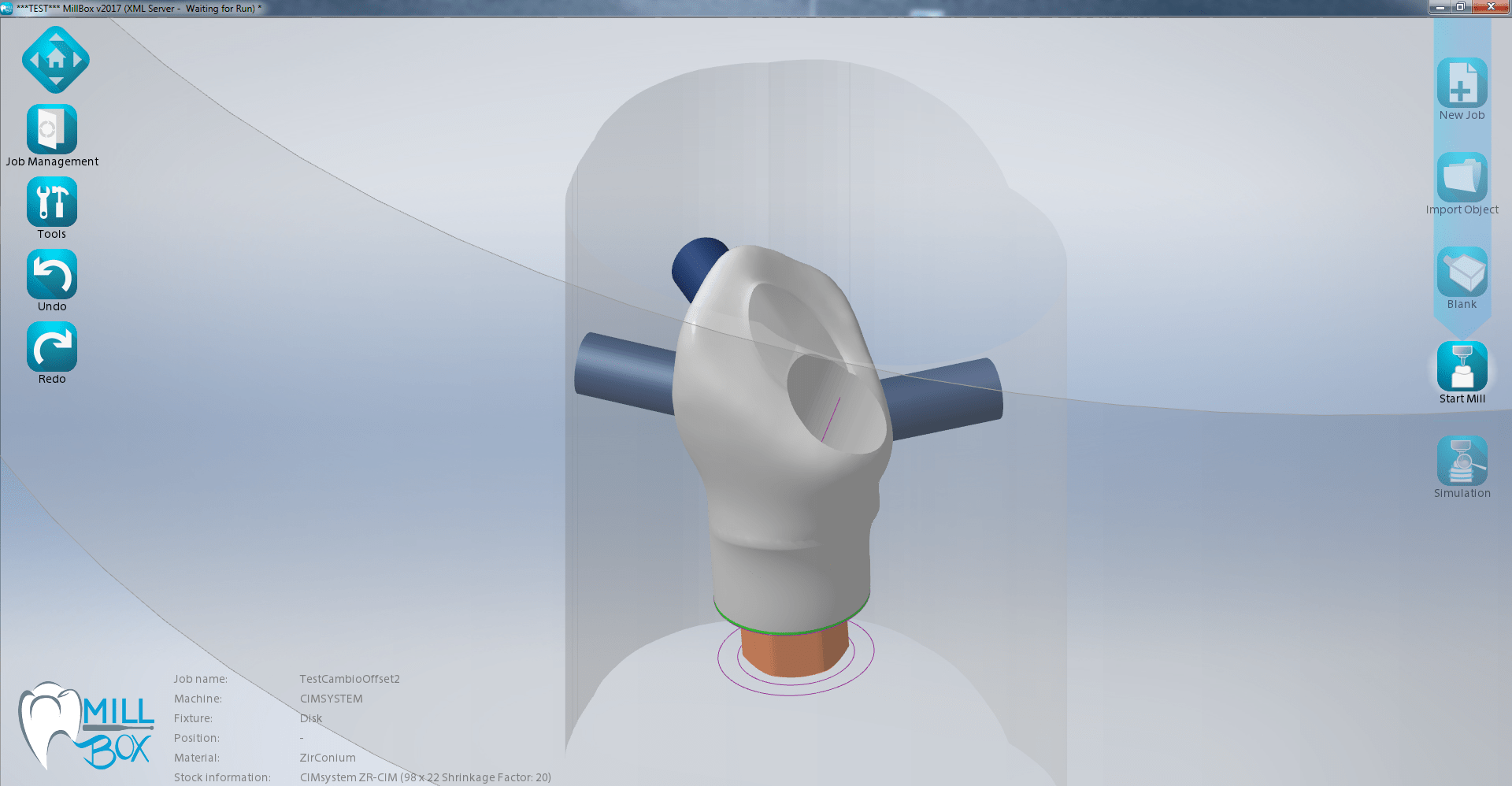

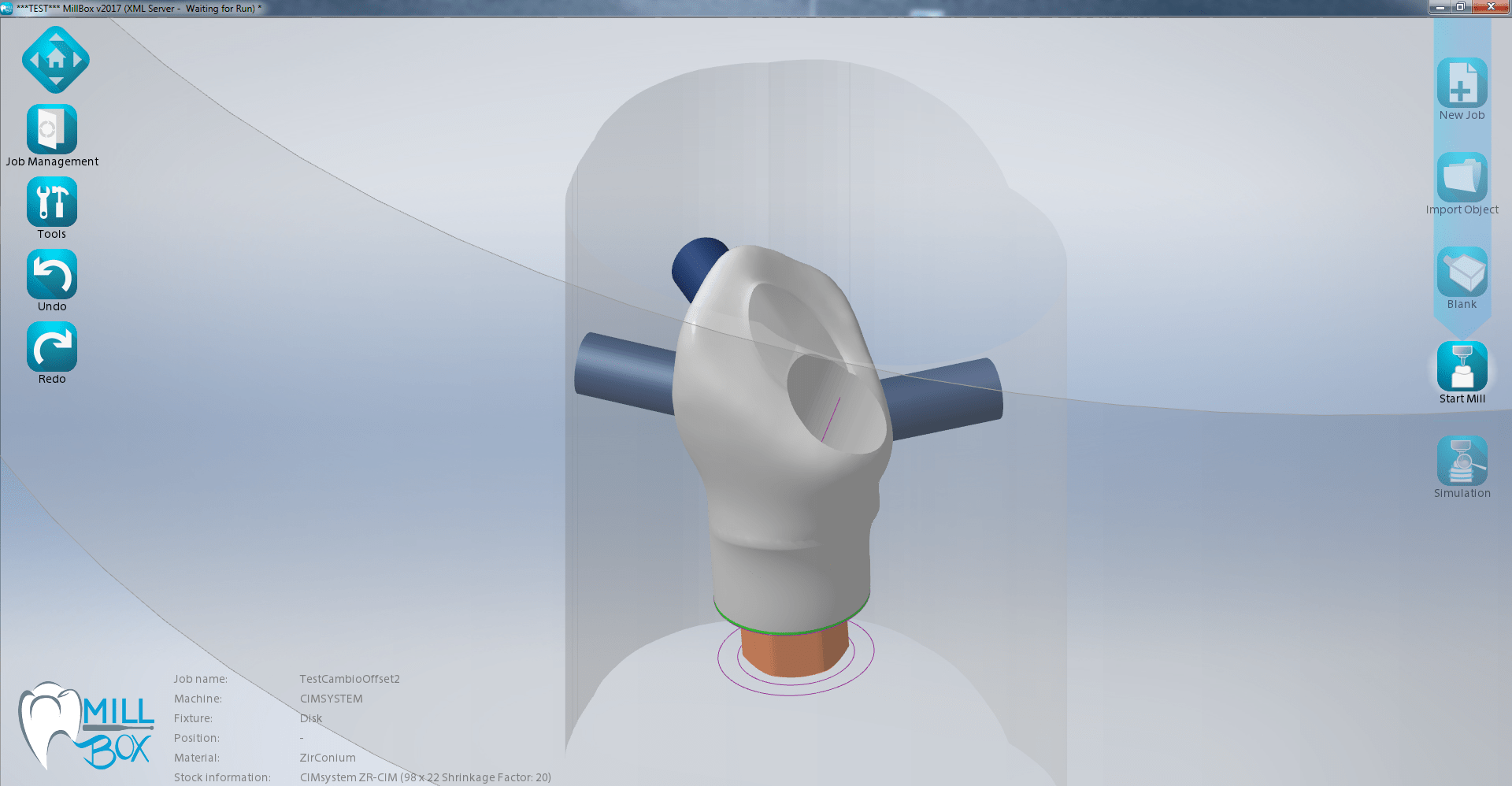

MillBox can manage machines with open face/C-clamp fixtures. This allows you to place a part with additional facial details oriented at the edge of the disc. MillBox will mill at the edge of the collar to allow direct access to the part. This typically results in moving the rotation axis to 90 degrees, as shown.

The tilting axis may pivot back and forth up to 30 degrees to get better detail.

If the milled implant does not fit perfectly in the analog / implant, you can make adjustments directly within MillBox to correct the issue. This tool allows for adjustments in all axes as well as the capability to add this information/preference to a replacement library for future use.

This allows you to solve a fit issue on the fly.

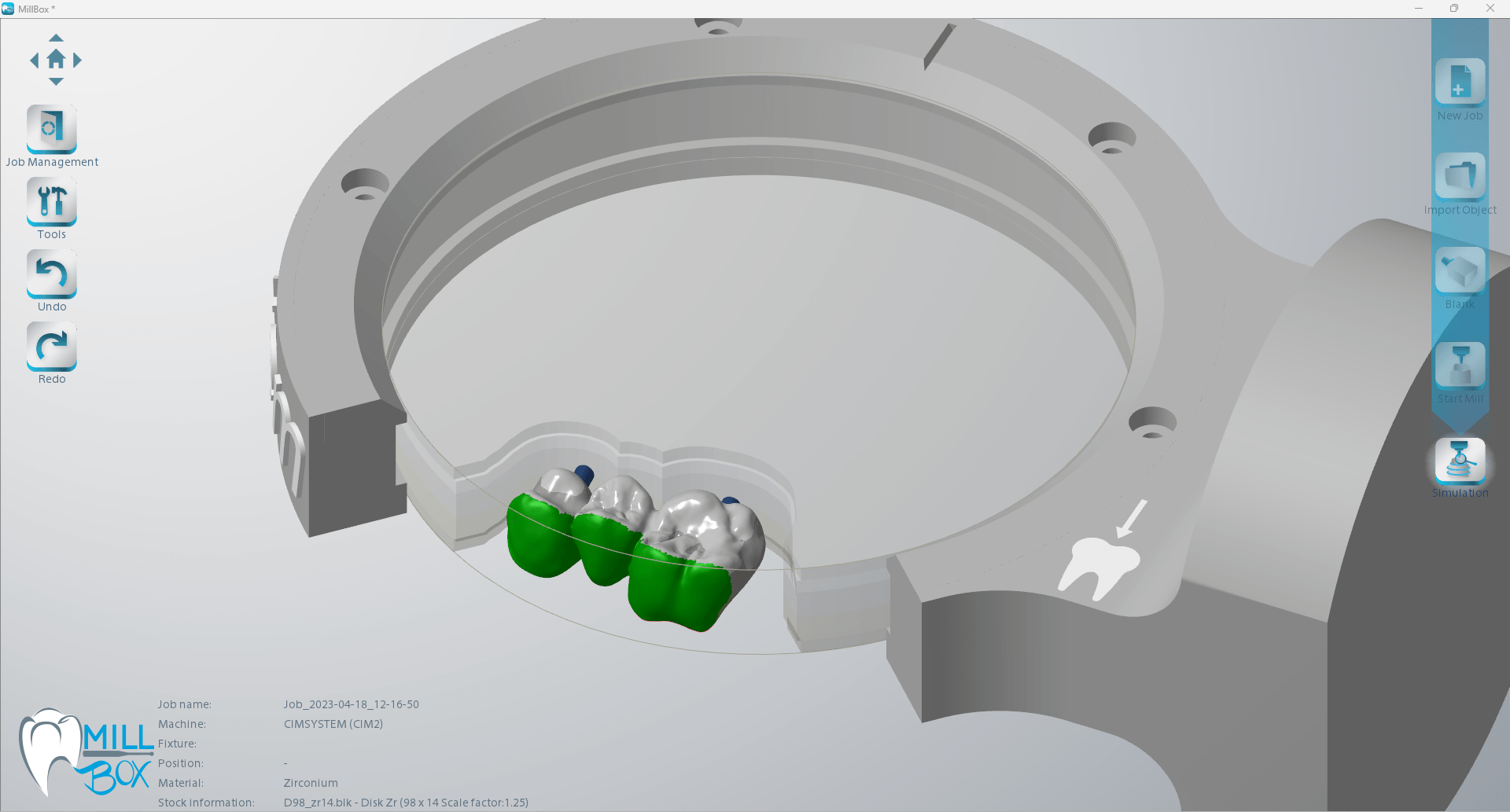

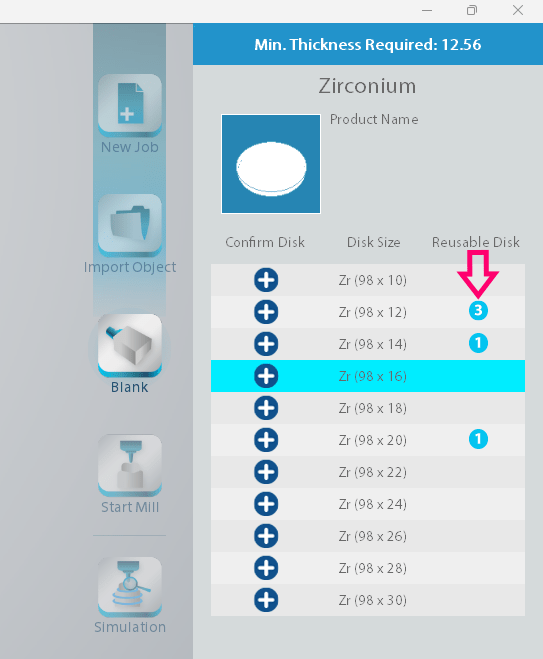

Navigate to the section that shows a list of partially used discs. In this area, MillBox can automatically select/suggest items from available disks in your library.

MillBox analyzes existing materials and will try to suggest a disc with the minimum space remaining that can still fit all restorations imported in the job. This Intelligent Stock Selection helps you utilize previously used material before allocating a new disc for milling.

ADVANCED

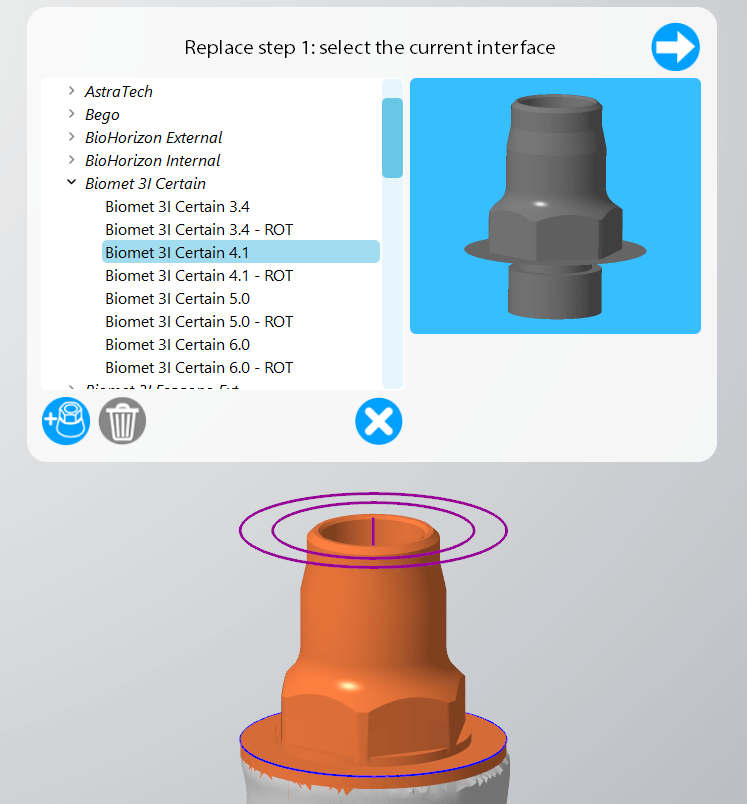

Added Support for displaying simultaneously Implant Replace Interfaces belonging to the same group.

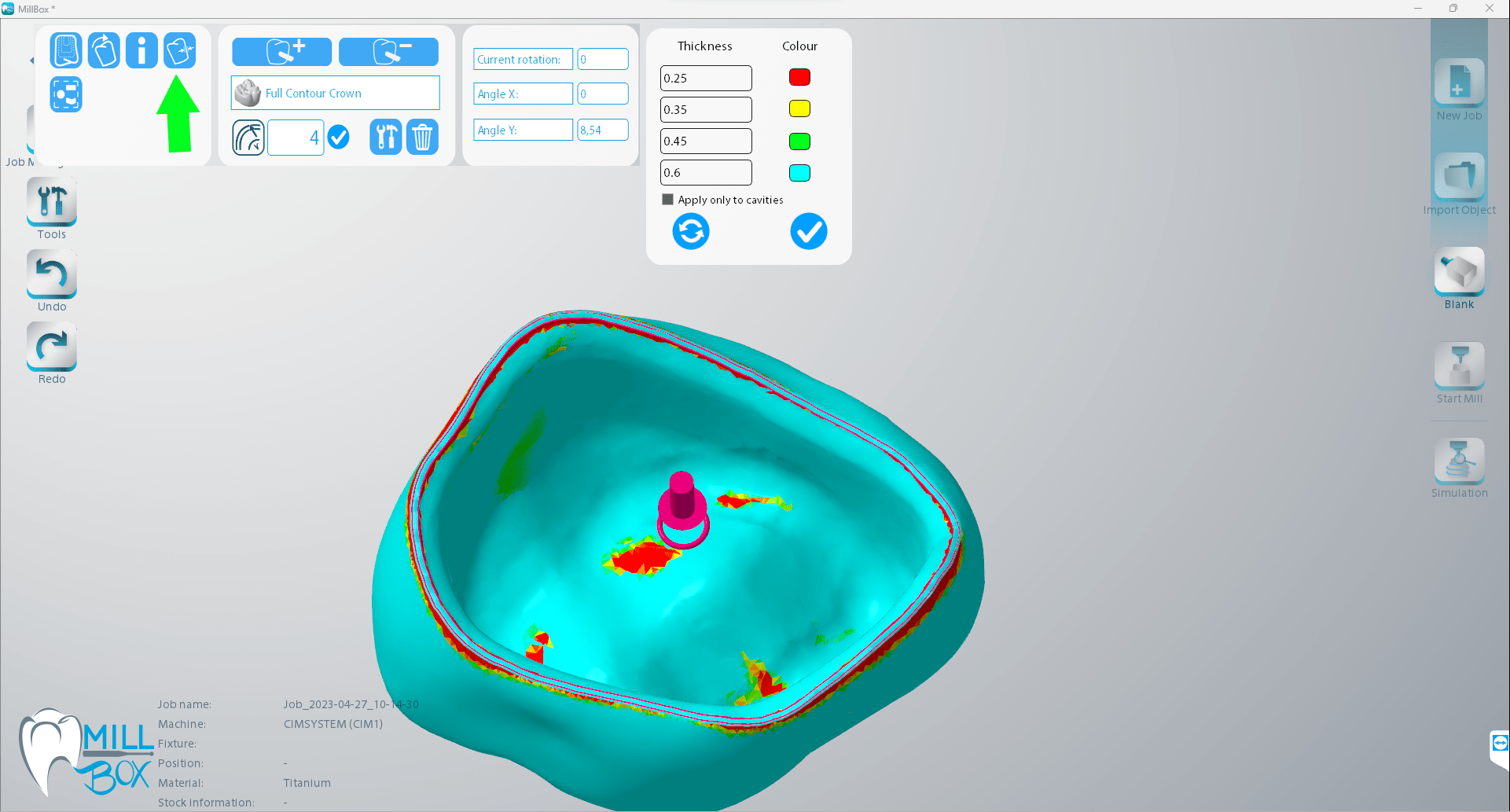

Visualize a thickness color-map superimposed on the restoration to be milled. When you select this tool, a colour-legend with pre-set and customizable thicknesses will be displayed, and the mesh will be coloured by thickness. The thickness legend can be unique and custom for each material through MillBox’s configuration. Users can click any object to analyze and display its thickness when the tool is activated.

It’s possible to mill only some objects, the calculation will start in the background for selected objects, and the % of the calculation will be shown in objects area. There will be no tools information dialogue and no request to update tools usage, both dialogues are confirmed in the background MillBox. Clicking on the icon that replaces objects milled will display information on the object and the possibility of opening the project that contains it.

This feature can be applied to abutments that have an angled screw hole. This allows the user to change the orientation of the occlusal hole. Since the milling result will be changed compared to the original design, it is recommended that the user carefully checks the changes to ensure that it is still suitable for their application.

When the tool is active, you can simply click from one part to the next to continue analyzing various parts in the job.