Make&Mill

CIMSystem

Make&Mill™

A Hybrid Solution for Subtractive & Additive Technologies

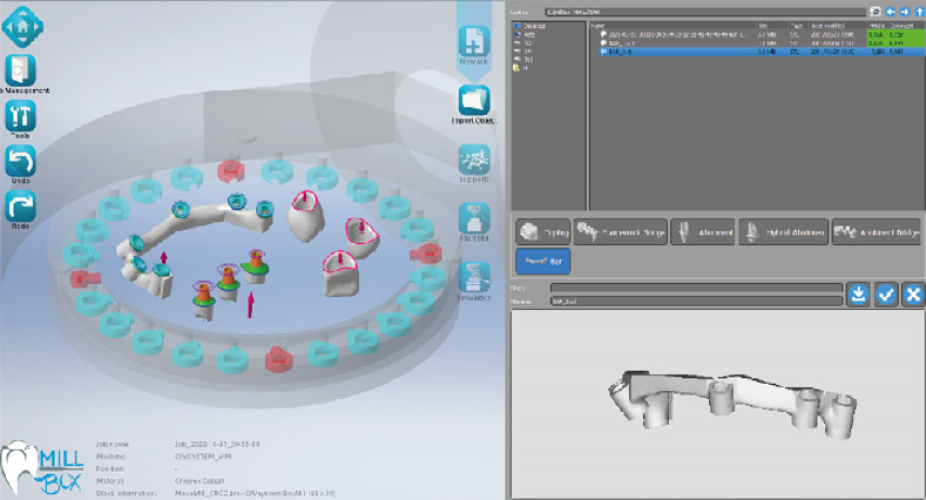

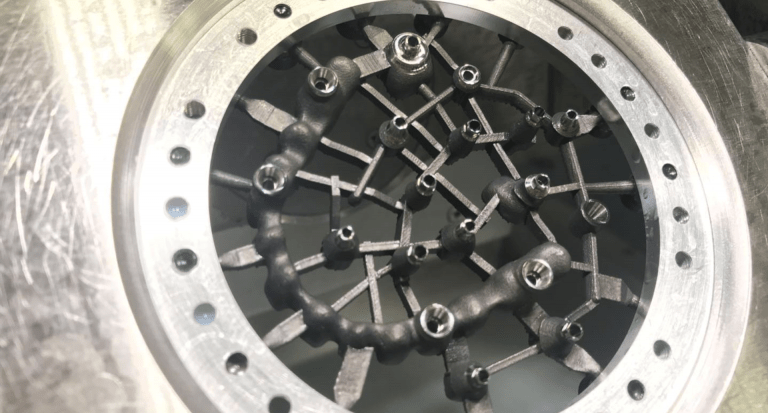

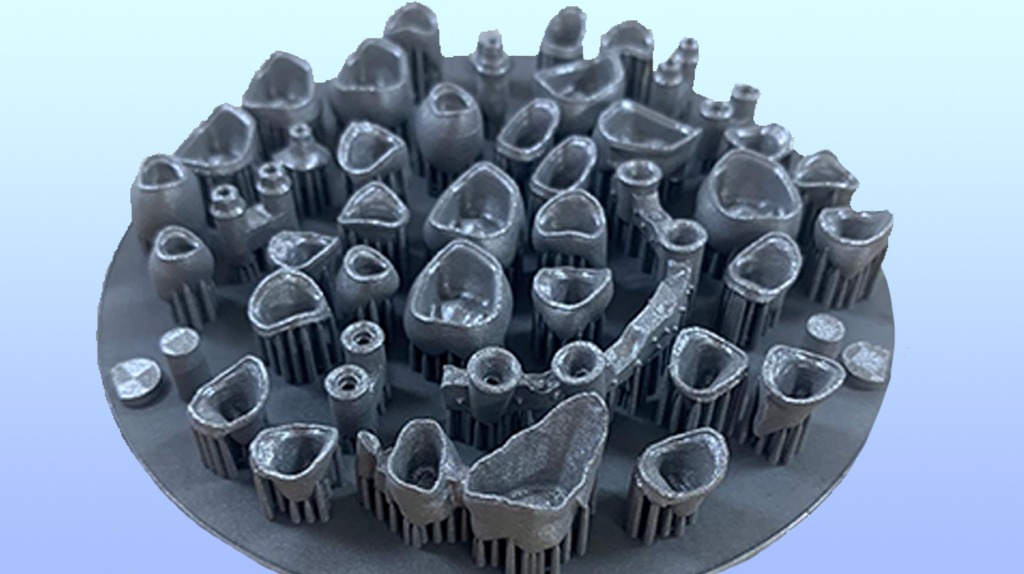

Make&Mill is an add-on module for MillBox that's developed to serve two different manufacturing technologies, additive and subtractive--all in one single software application.

Whether in sintered metal or resin 3D-printed, the produced dental part via additive manufacturing, will be brought to perfection by milling.

Features

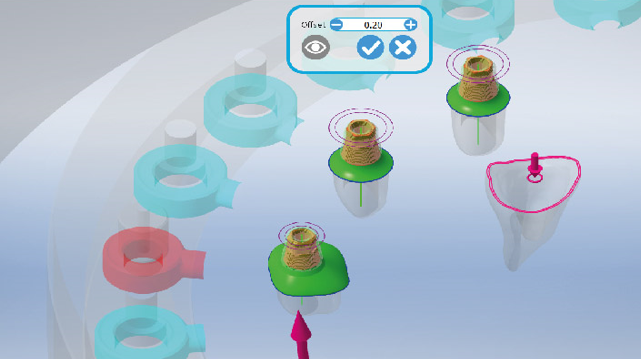

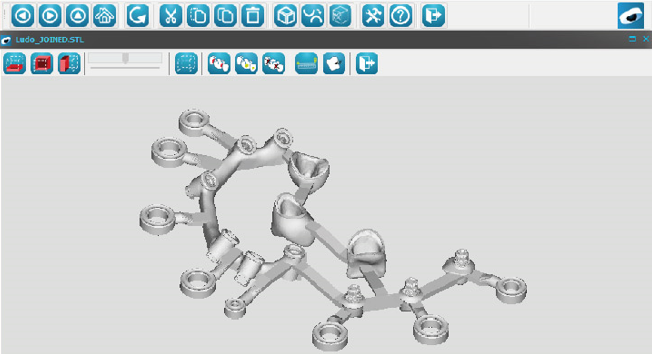

Easy Addition of the Parts

Great potential is the possibility of choosing the part to be finished and adding the material at the desired point.

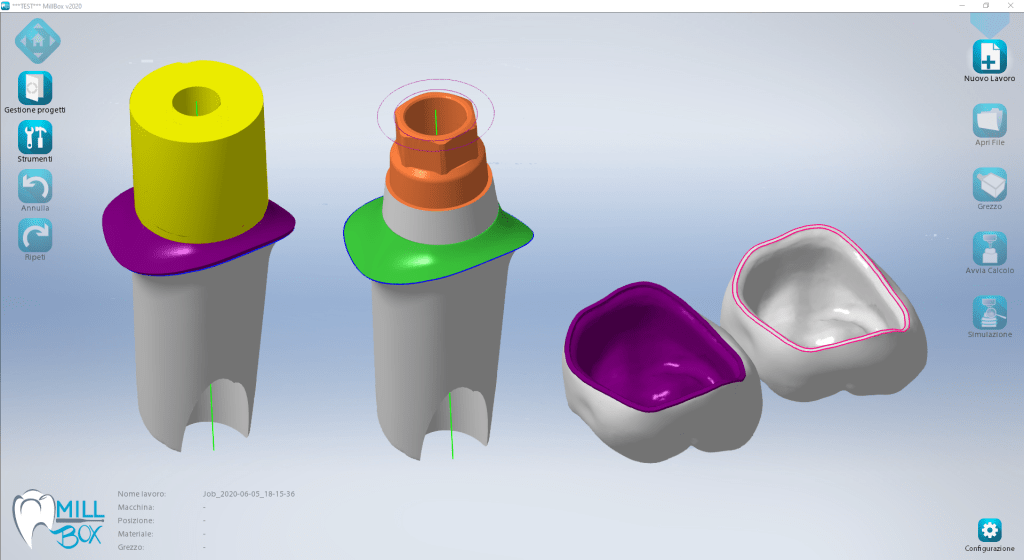

Fast Automatic Recognition

Automatic function for the recognition of parts with an implant, the system can create custom caps according to different personal technical needs.

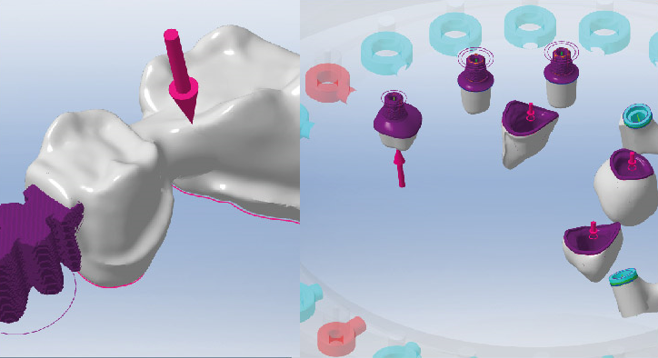

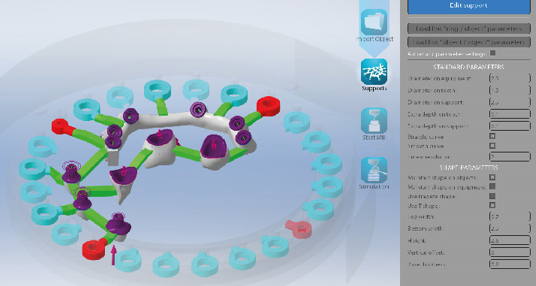

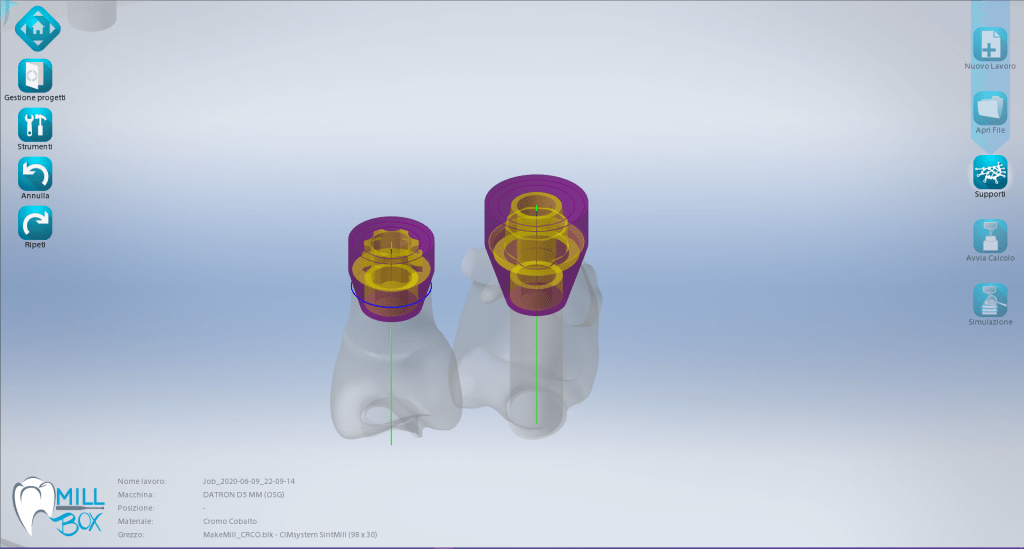

Easy Calibration | Simple calibrating procedure and support insertion.

With Make&Mill it is possible to remove and reposition the support equipment simply and error-free.

Perfect Milling on Both Sides and “From Plate”

Make&Mill is a hybrid solution that allows machining on both sides and allows a perfect finishing of all the fitting parts. It is also possible to process the parts with an implant by machining from one side with the specific module, “from plate”.

Requirements

Minimum Requirements |

Recommended Requirements |

|

Hardware |

Intel 64bit or AMD 64bit Processor RAM 16/32 GB HDD: SSD\Msata > 500 GB Graphic Card Nvidia RTX\GTX 4 GB RAM Monitor 24″ |

Intel I9 64bit or AMD Ryzen 9 64bit RAM 32 GB HDD: SSD\Msata 1 Tb Graphic Card Nvidia RTX 4 GB Monitor 24″ |

Operating System |

Windows 10 64bit Windows 11 64bit |

Windows 10 64bit |