Oqton

Oqton

Dental Manufacturing OS

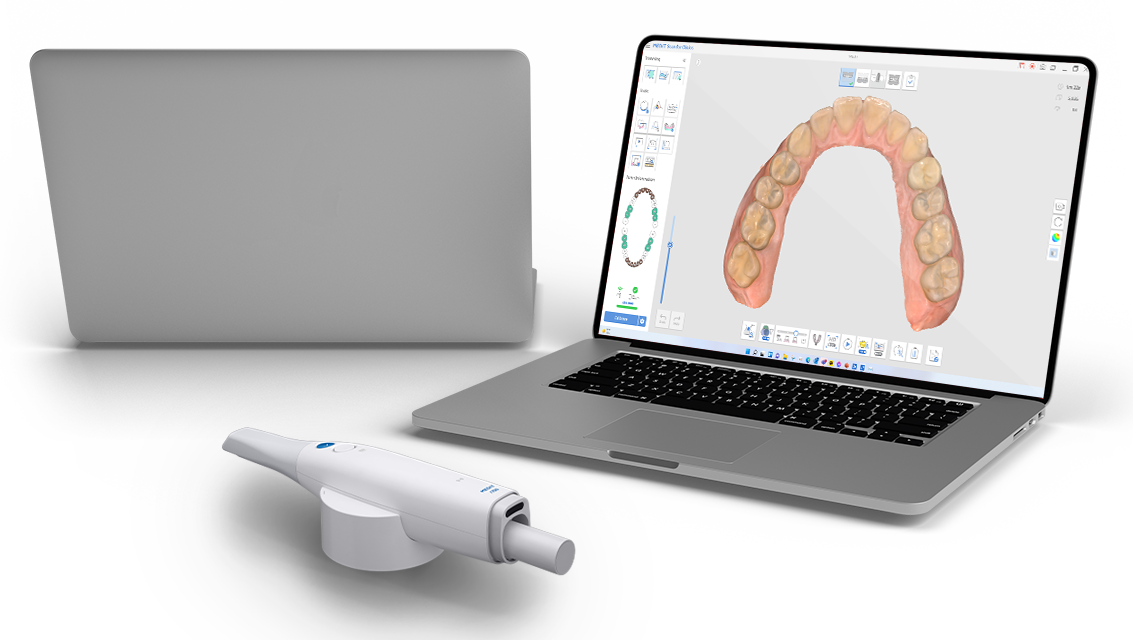

Automated manufacturing operating system (OS) for dental labs, powered by AI

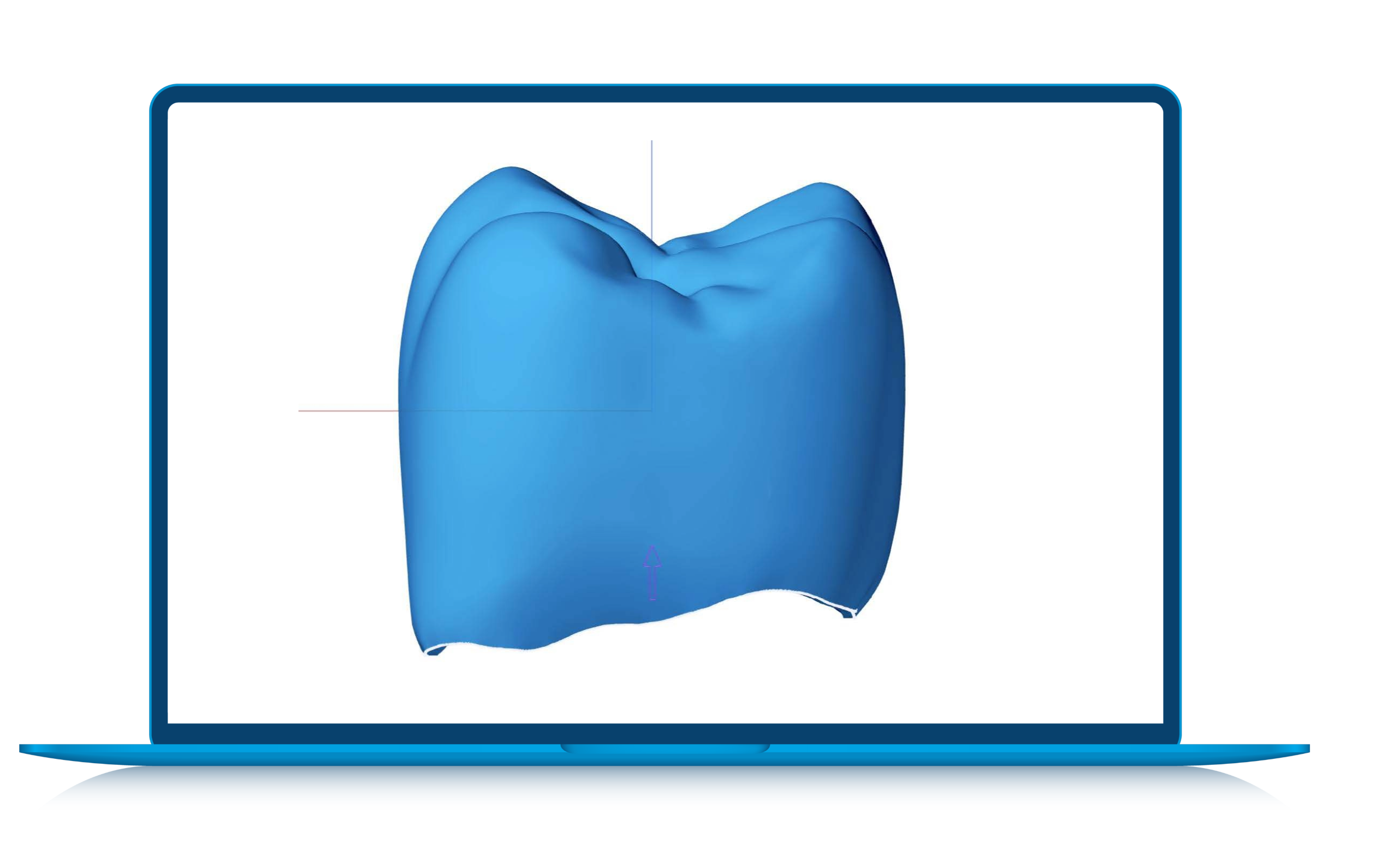

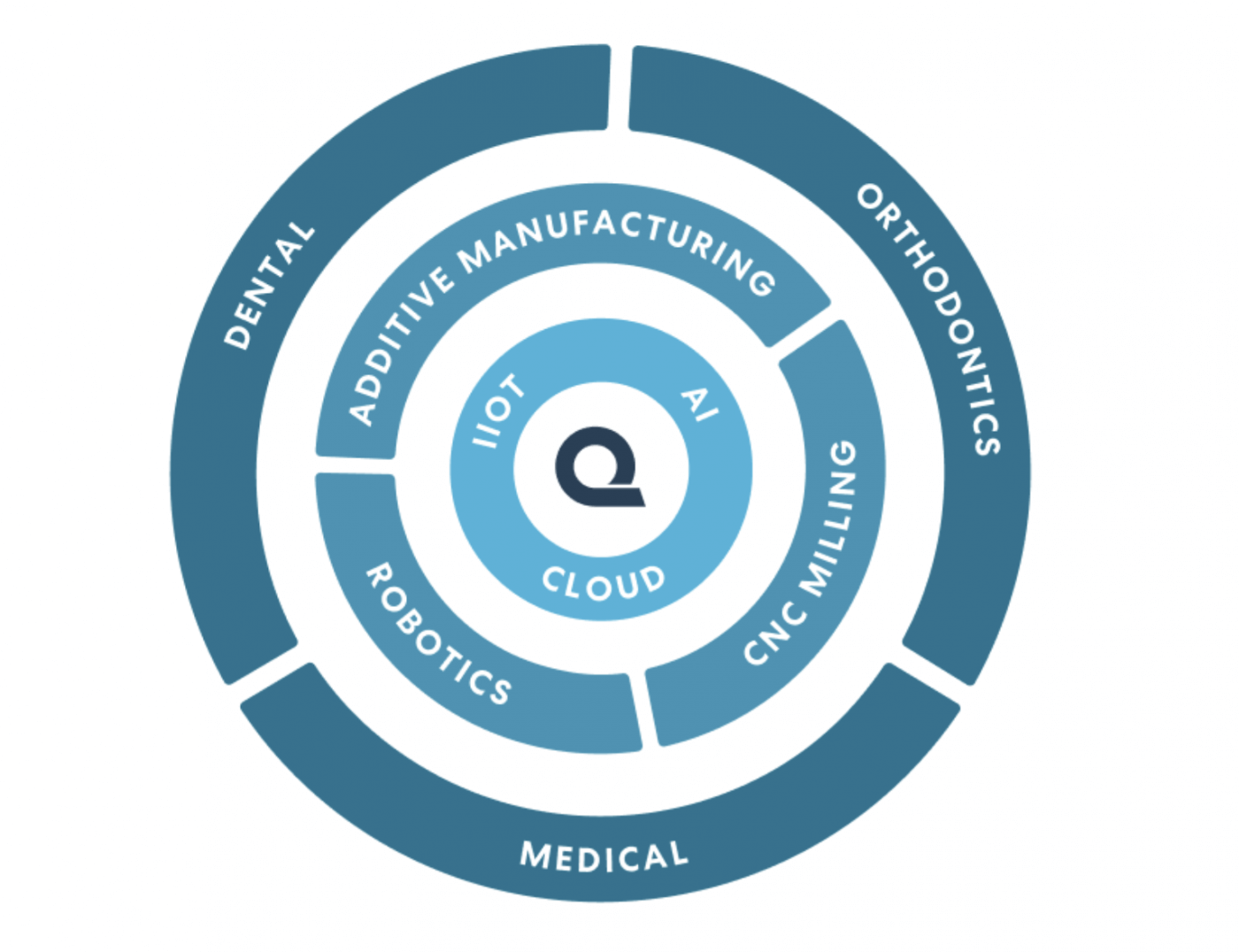

Oqton is an all-in-one manufacturing operation system designed for dental labs and powered by artificial intelligence. Thanks to its automated data preparation, you can streamline additive manufacturing and CAM operations while improving machine productivity and managing your entire production workflow creating full traceability.

Oqton. AI-driven dental production.

Oqton provides automated dental workflows to help you meet growing production goals while significantly reducing manpower requirements. An end-to-end, integrated dental production system, Oqton ensures full traceability to future-proof your business.

The Oqton platform is agnostic and can replace multiple disconnected software applications across your machines.

Features

Oqton’s partners. Industry well-known players.

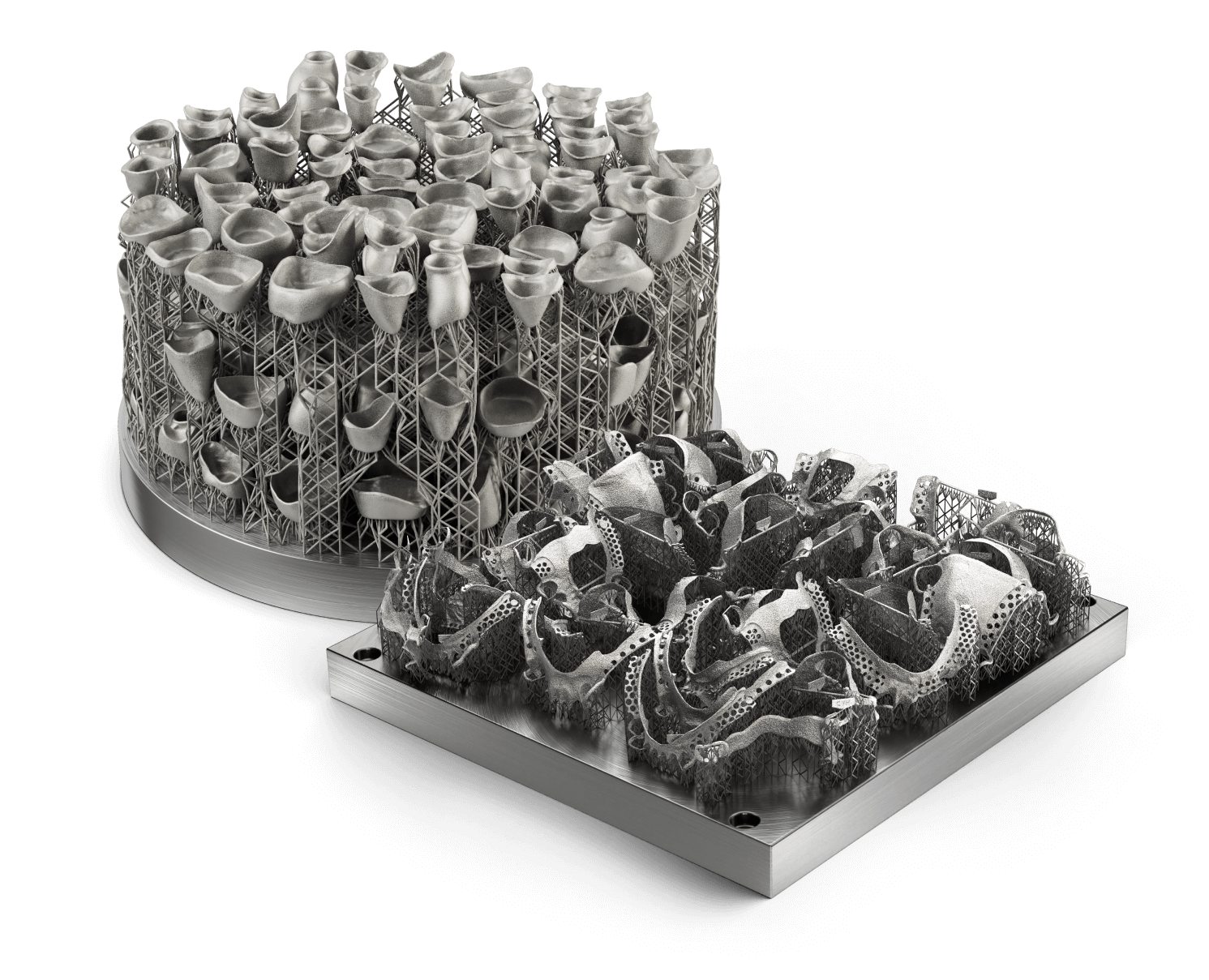

3D Printing Applications

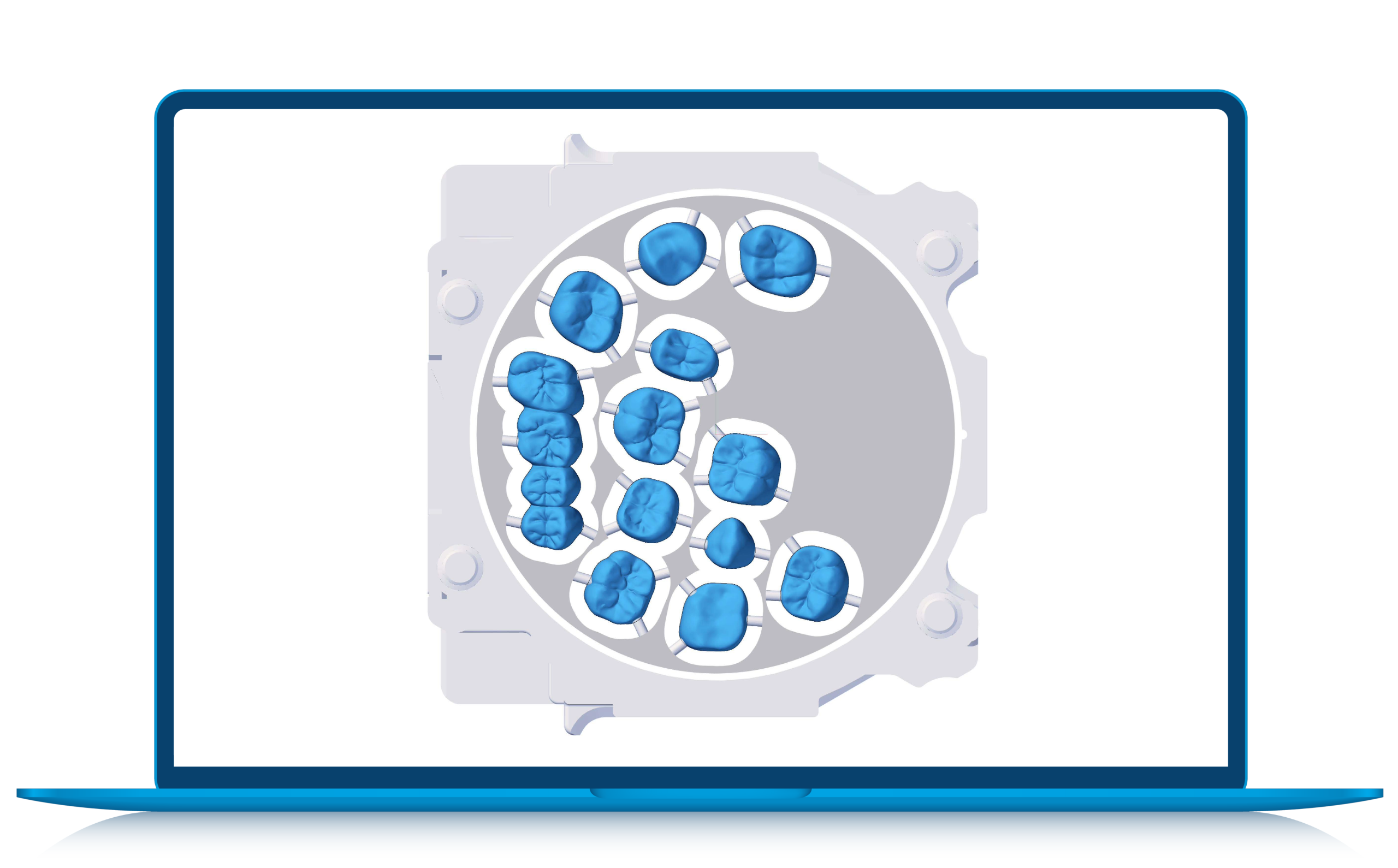

Connect and Automate Clear Aligners Production

- Oqton connects design, 3D printing, thermoforming, laser marking, CNC milling, labelling and packaging manufacturing processes.

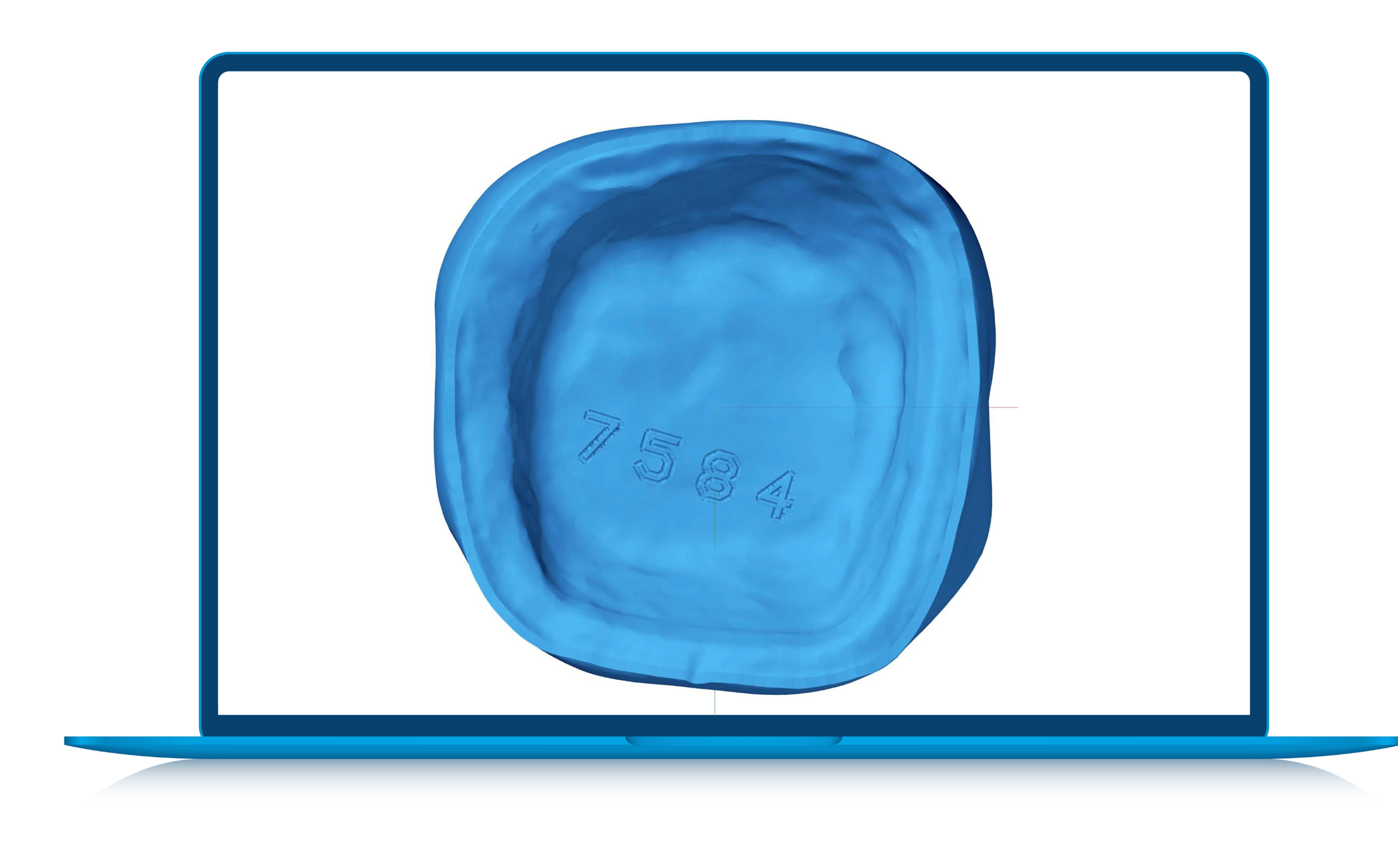

- Fully automated data preparations and optimized nesting for cost-effective production

- Easily scalable, across multiple locations, and ready for any volume

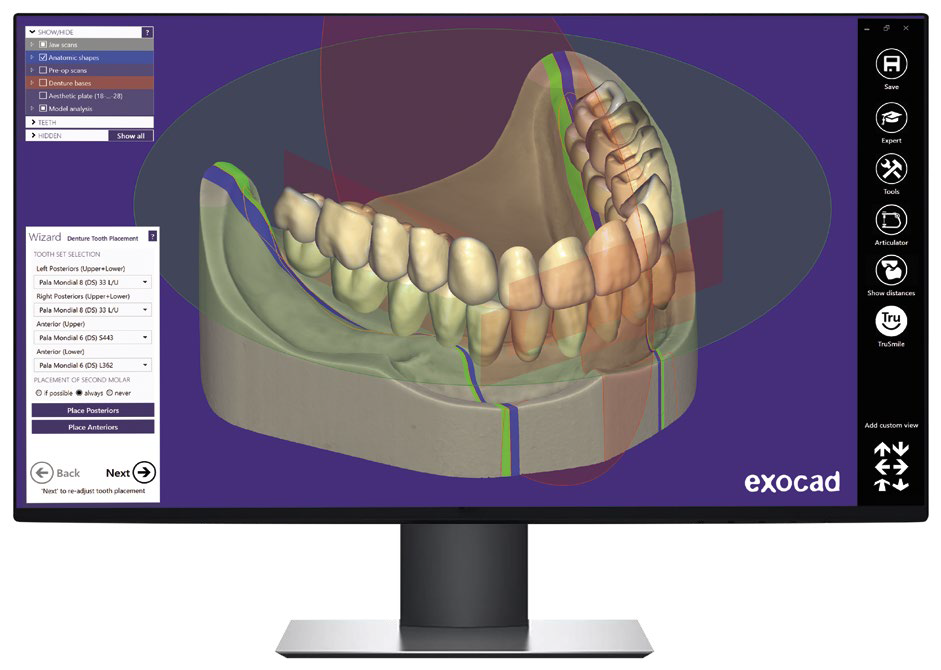

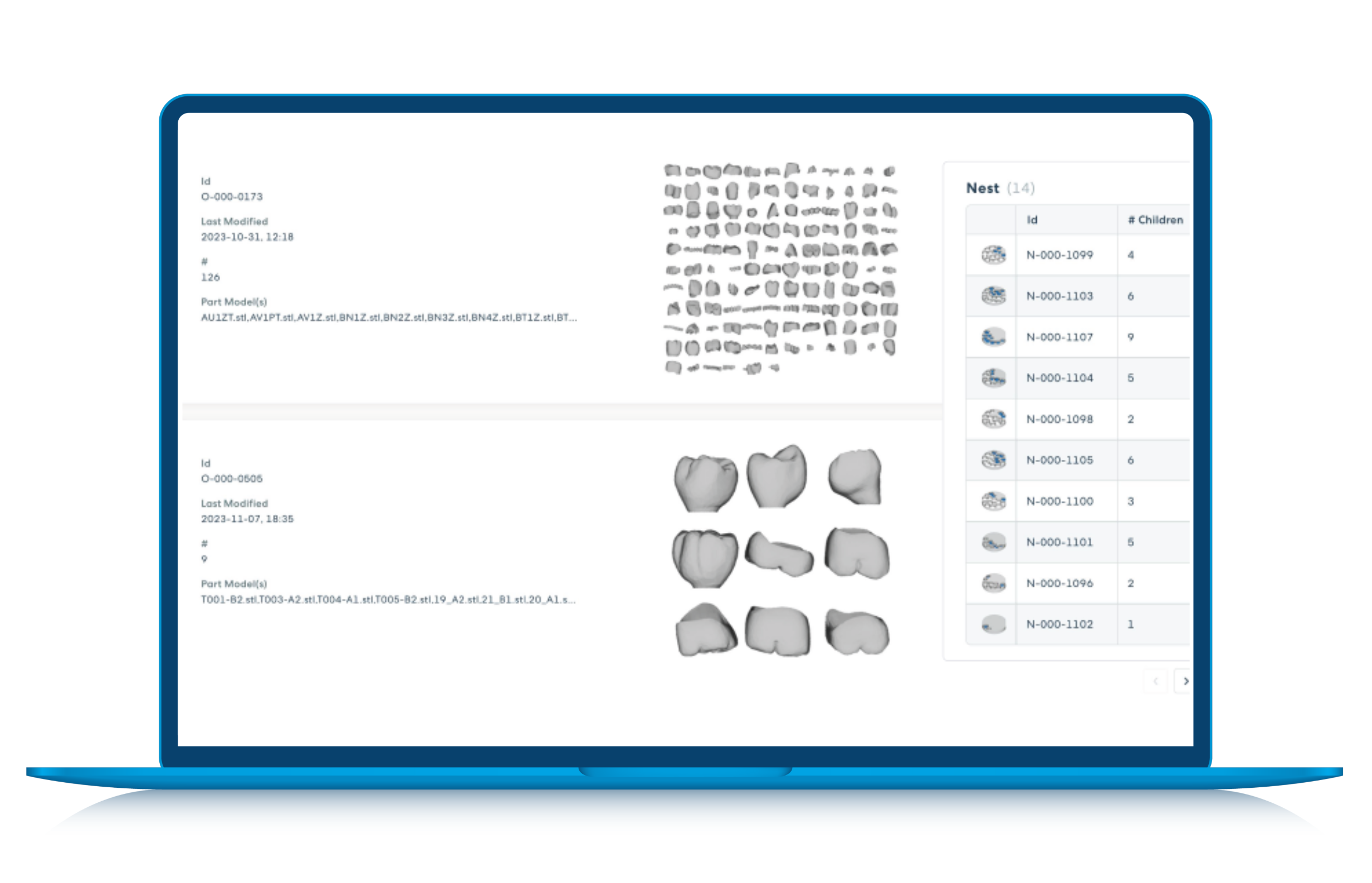

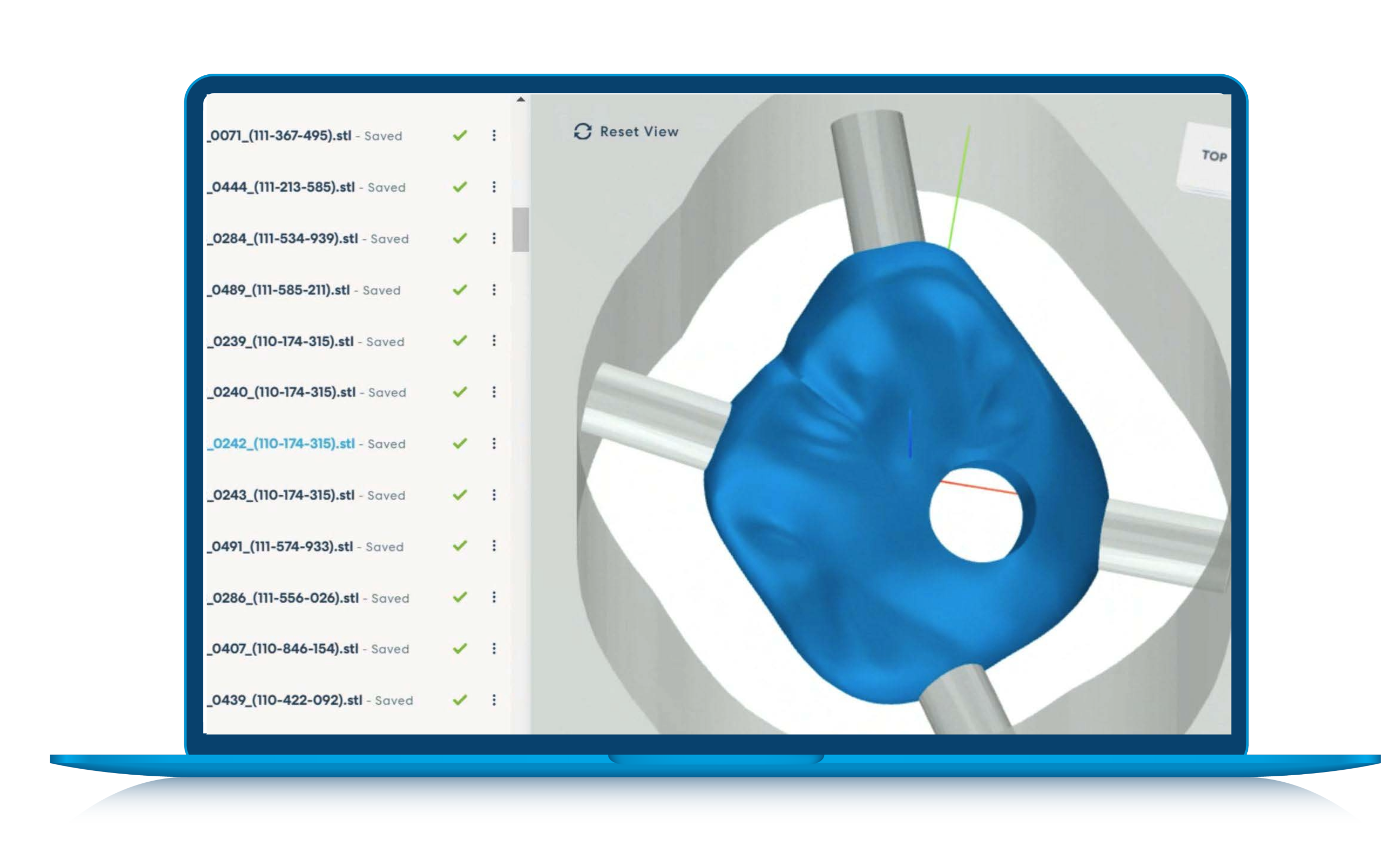

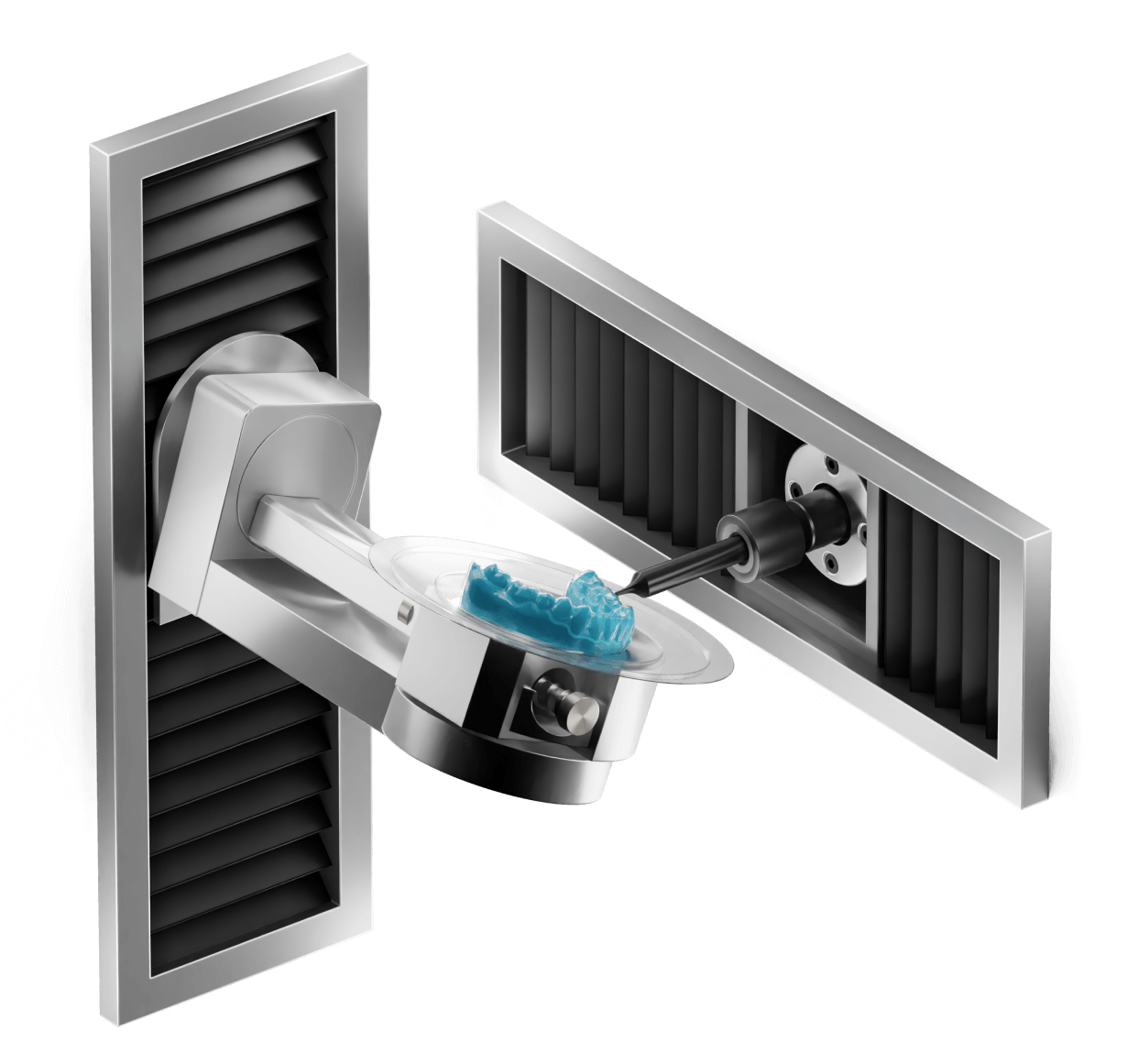

No More Repetitive Tasks in CNC Milling

- AI-driven automation of CAM workflows, including automatic stock selection, nesting, and toolpath generation

- Machine learning capabilities for orientation and pin placement

- Optimized machining efficiency and consistent results based on feature detection and automated assignment of milling templates.

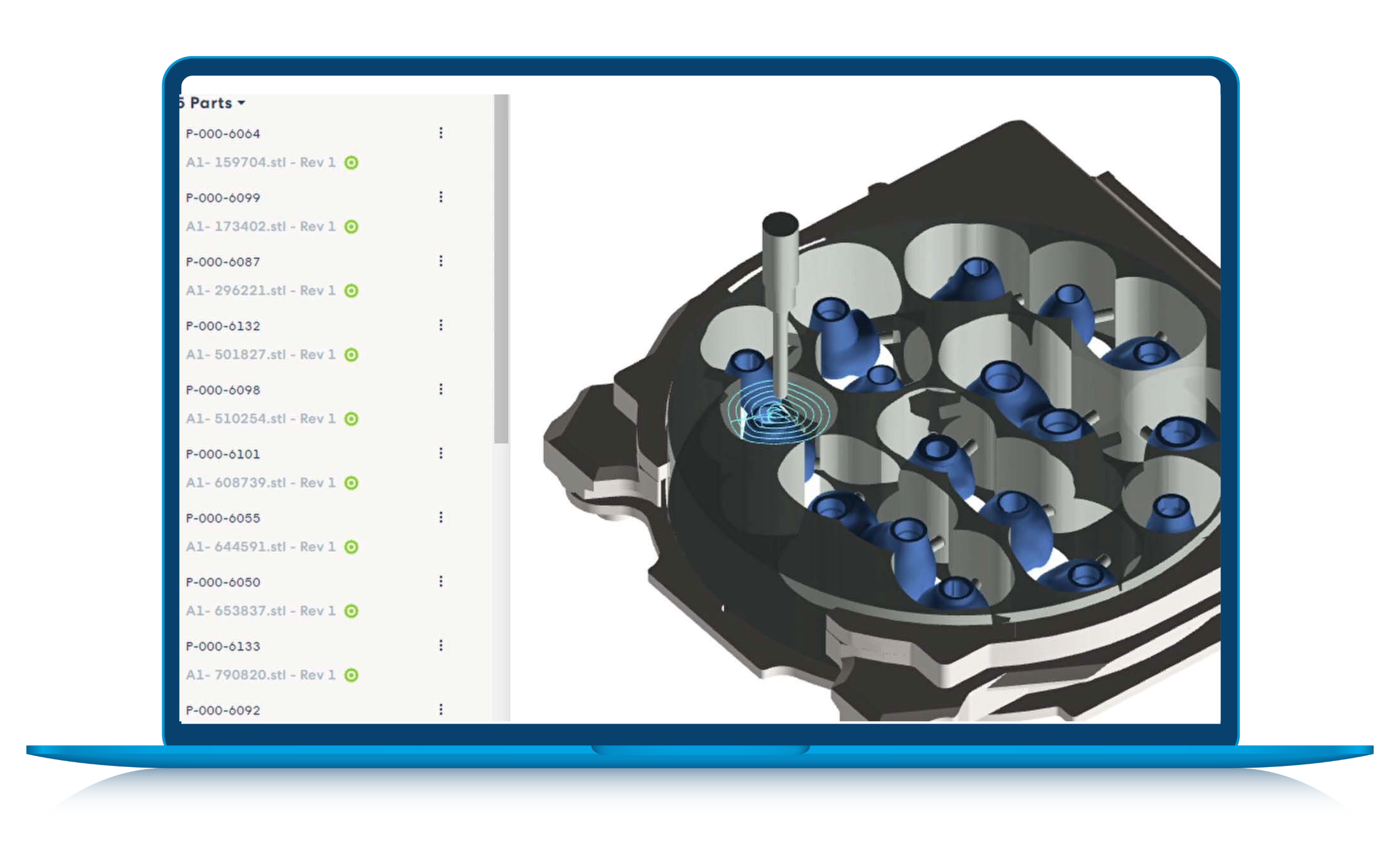

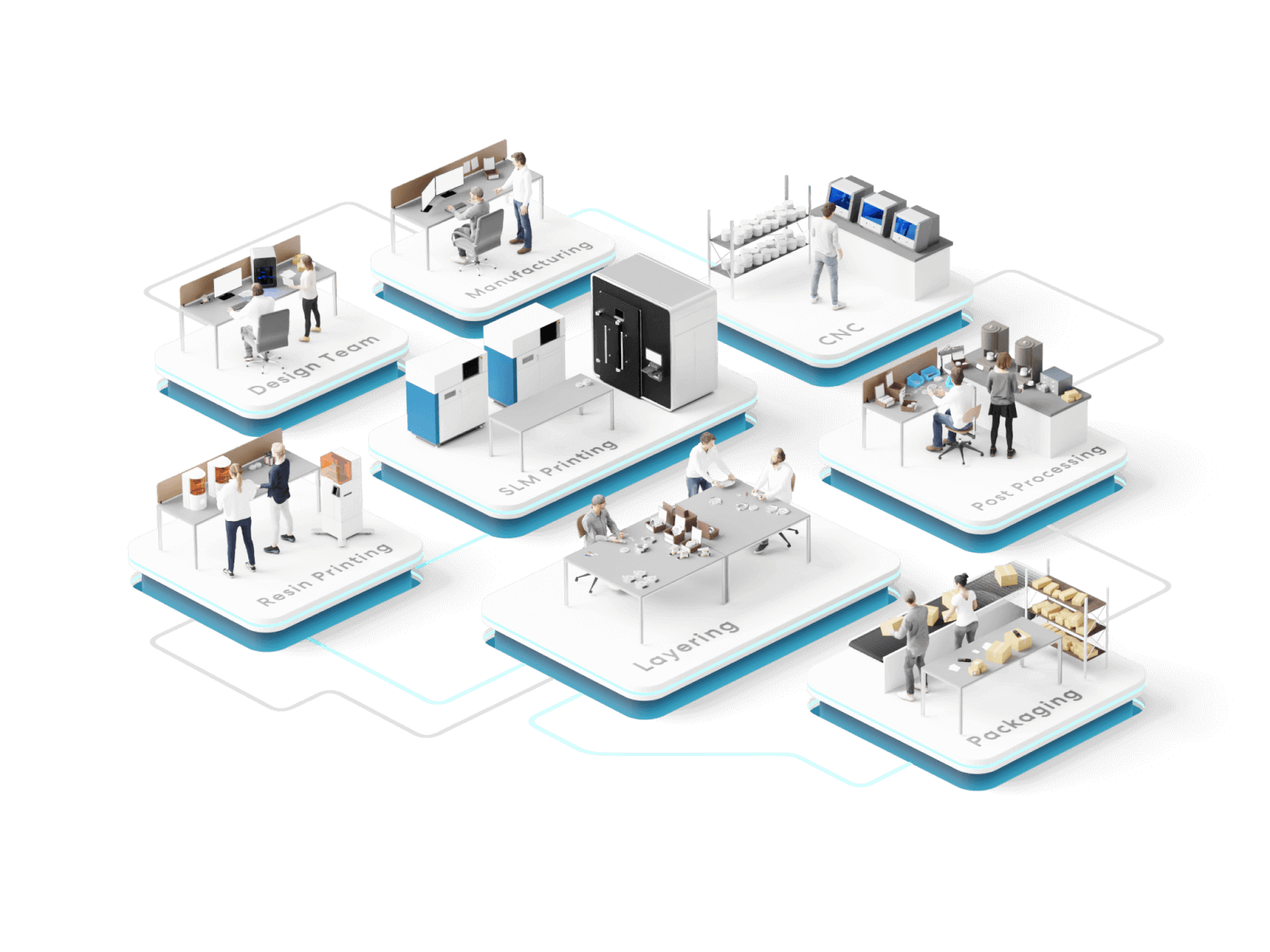

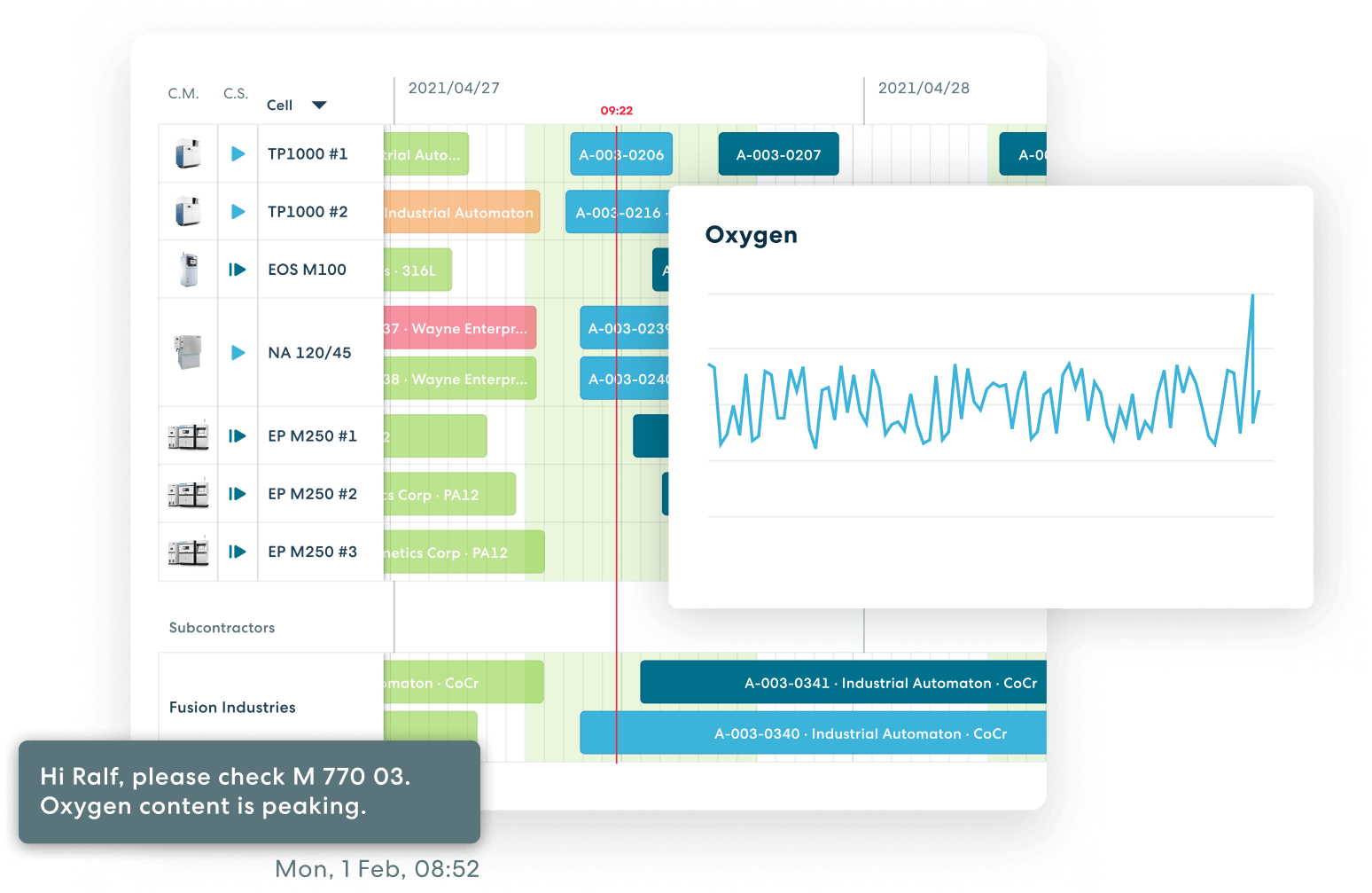

Highly Efficient Production Management

- Prepare, plan, schedule, track and trace your entire production facilities

- End-to-end traceability of materials, tools, parts and jobs with full revision history

- Rich data can be gathered automatically by integrating and connecting CAM, MES and IoT

Dental CNC Milling Workflow

Discover how Manufacturing OS can enhance productivity in your dental CNC milling workflow.