Fast, Accurate Models Drive Orthodontic Appliance Development

“Since we began leveraging Stratasys’ 3D printing technology, we’ve experienced faster turnarounds, better capabilities and a vibrant, growing business”- James Bonham, Specialty Appliances Partner

Clear Savings

3D printing technology provides a faster, better and more affordable technique to creating a one-to-one replica of a patient’s mouth. Georgia-based Specialty Appliances is an advanced digital dental lab that produces high-quality orthodontic appliances and dental models that has adopted 3D printing technology into its daily workflow.

Using both the Objet Eden260V and Eden500V 3D printers from Stratasys, the company is able to mass produce accurate and durable dental models using VeroDentPlus material, resulting in fewer appointments and shorter treatment time for patients.

3D Printing Revolutionizing Orthodontics

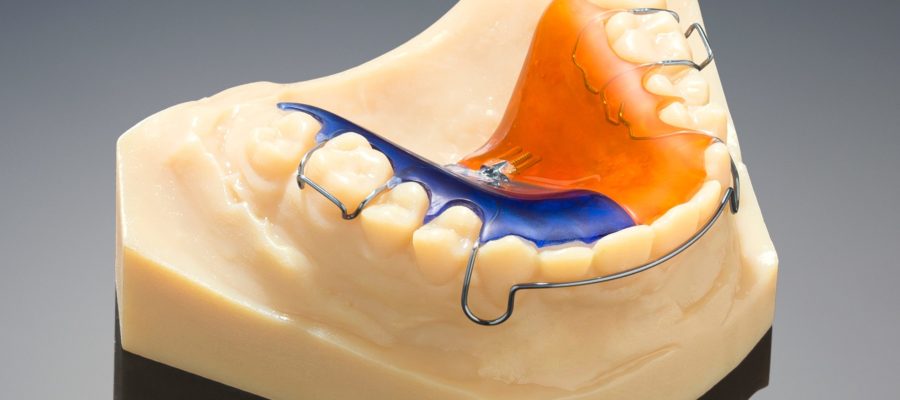

VP of Specialty Appliances Arlen Hurt saw first-hand how 3D printing solutions could improve her business and change the field of orthodontics. “Everything that we do in the development of an orthodontic appliance—whether it be a palatal expander or a Herbst appliance to correct an overbite—is based on a physical model,” Hurt explains. “With the advent of intraoral scanners, it became clear that printing dental models with a 3D printer would be faster, more accurate and less prone to human error than the traditional impression-based approach.” Hurt adds that, “intraoral scanners and Stratasys 3D Printers have allowed us to deliver custom appliances a week sooner without the need to take impressions.”

Specialty Appliances’ first 3D printer was the Objet Eden 260V from Stratasys in 2011 and saw an increase in printer usage in cases from 6% to 24% in just 18 months. The company now uses three Objet 3D printers in-house.

“We looked at and evaluated every printer on the market, but we were drawn to Stratasys by its large number of references, easier approach to post-processing, and fewer maintenance issues,” Hurt recalls. “Once our usage exploded, we added the third printer because when you depend on a piece of equipment for production, you need a backup to support rapid growth.”

Stone Models vs. 3D Prints

Traditional stone models usually take a week to produce from an impression. With 3D printing, models can be ready on the same day that the scan is created. Other benefits of 3D printing over stone models include a high level of accuracy and durability. With a 3D scan, Specialty Appliances can produce dental models from intraoral scan data with a resolution that is within 40 microns of dimensions of the patient’s actual teeth. The durability of 3D printed dental models also prevent crumbling and deterioration as with stone models. The Objet 3D printer allows Specialty Appliances to make multiple models on a single print, increasing productivity while spending less.

Hurt says, “Thirty years ago, nobody would have thought that this was possible, but with advances in materials and productivity gains, we know where our business is headed, and that 3D printing will play an important role in our growth and success”

Fewer Appointments, Less Treatment Time

One of the most notable benefits is the need for fewer appointments and less treatment time for patients. In other words, patients can get their braces off sooner and avoid potential relapse or movement of the teeth between procedures.

“Taking impressions can consume entire appointments,” notes James Bonham, a Specialty Appliances partner who manages sales and marketing. He says that 3D printing shortened a typical procedure—like mounting an appliance through a band or crown seated on the molars—from six weeks and three appointments to two weeks and two appointments. “Everyone benefits: the orthodontist, his staff and most importantly, the patient.”

“Stratasys 3D Printers have helped us carve out a unique spot in the marketplace by enabling us to provide services to customers in a digital 3D world,” Bonham continues. “Since we began leveraging Stratasys 3D printing technology, we’ve experienced faster turnarounds, better capabilities and a vibrant, growing business.”