Digital Dentistry Expands to Dental Institutes

“In cases where the complex, multi-faceted dental surgical procedures are required, the ability to predetermine the best possible outcome is the key.”- David Keynan, DentalCare

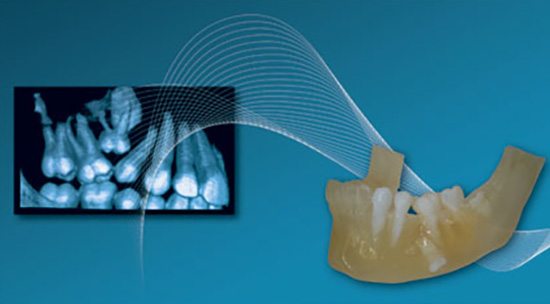

X-Ray Vision

Considered one of the largest national dental institutes for CT and X-Ray scans, DentalCare has stayed ahead of the competition by integrating CT and 3D printing solutions. This enables them to lead the market and fulfill orders with speed and efficiency without having to sacrifice on the quality of the final product.

The Challenge

DentalCare provides dental and orthodontic services to treatment clinics that include CT imaging, ICAT, digital panoramic images as well as 3D printed models. The company found itself in an optimal position for growth as their catalogue of services and offerings were robust and of high quality. In an effort to expand, DentalCare purchased an Objet Eden260V 3D printer in order to streamline their business and increase their output that would be cost-effective.

Complex, multi-faceted surgical procedures require the ability to predetermine the best possible outcome. Dental modeling – made possible by advanced 3D printing systems, enables dentists to evaluate several different treatment scenarios before deciding on a plan that ensures a patient’s needs are met. DentalCare might be involved in oral and maxillofacial surgery, dental trauma, oral pathology, dental reconstruction, correction of dental deformity and dental implants.

DentalCare wanted to optimize the outcome of comprehensive reconstructive oral procedures, while at the same time minimize invasiveness and patient discomfort. Their 3D printed models are widely used due to their accuracy, fast build time and ease of sterilization. They are also highly resilient, enabling drilling and fixing of screws and model plates. Additionally, the support removal process preserves thin and delicate structures while eliminating an after-production step that can degrade the model surface, making it possible to build complex dental models of anatomical structures. The fine-detail printing, adequate layer thickness and smooth surface output make Objet 3D printers suitable for all dental solutions provided by DentalCare.

The Solution

DentalCare was about to produce multiple real-scale models using the Objet Eden260V printer from Stratasys to identify the right solution for each case. The models created were easy to use, fast, durable and retained a high level of precision in the part’s finish- ensuring a high quality product for DentalCare’s customers.

The Results

Going digital has never been more important for the dental industry. DentalCare is an example of a major player in the dental market turning traditional CT images into digital, manufacture-ready dental models with short turnaround times thanks to 3D printers. Using the Objet Eden260V, the team’s technicians have an easier time producing models and their daily production output has skyrocketed. Going digital has seen DentalCare grow in quality and production, providing more dental solutions than ever before. Their investment has returned tenfold through increased business opportunities, customer orders and dental model production that is faster and at a reduced operating cost. 3D printing solutions help DentalCare to develop innovative models and stay ahead of the competition.